Zirconium-containing polyborosilazane precursor aerogel, silicon-boron-carbon-nitrogen/zirconium dioxide ceramic aerogel, and preparation method and application of ceramic aerogel

A technology of polyborosilazane and silicon boron carbon nitrogen, which is applied in the field of airgel materials, can solve the problems of dispersibility, limited performance, and the inability to achieve uniformity of composite material materials, and achieve the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

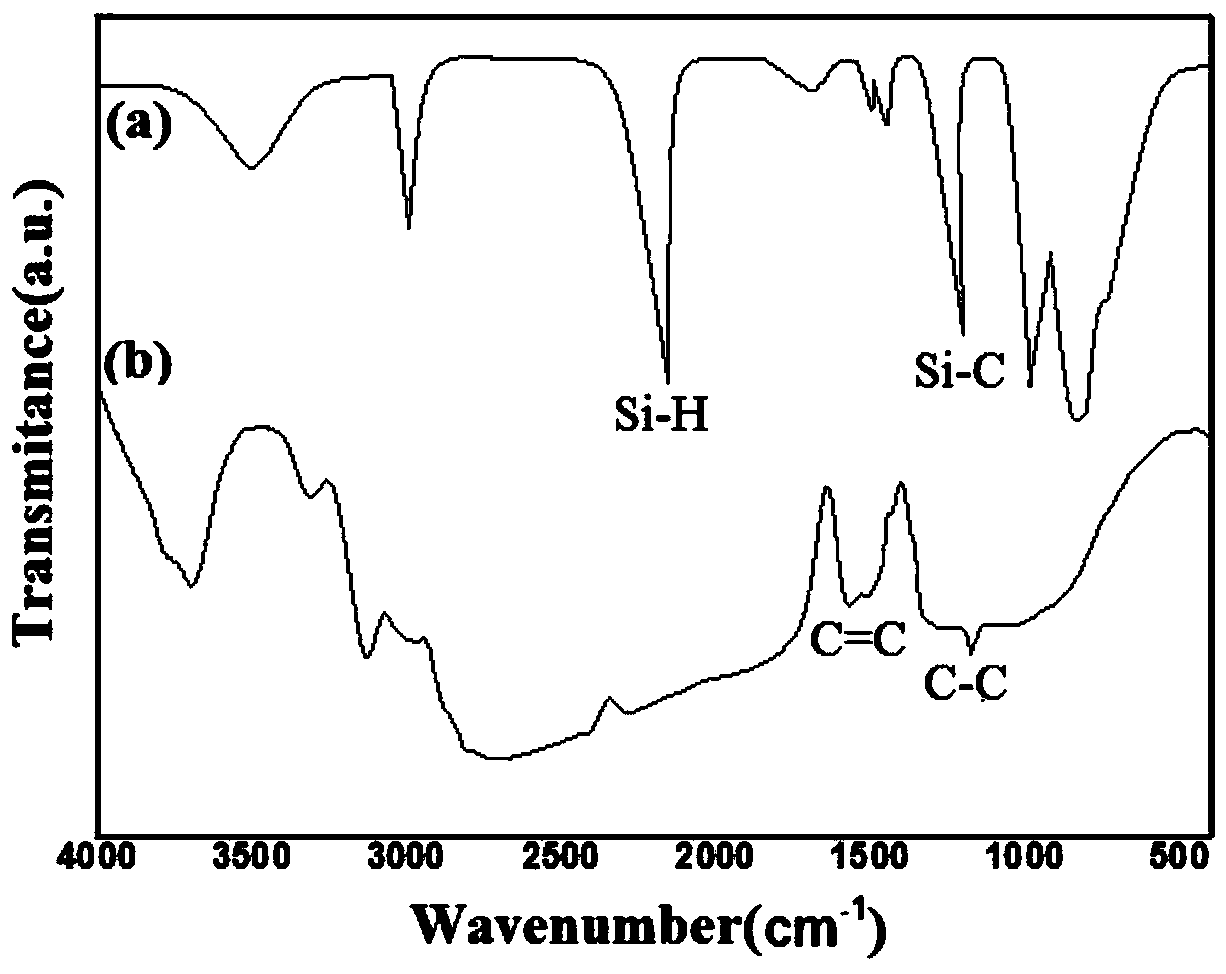

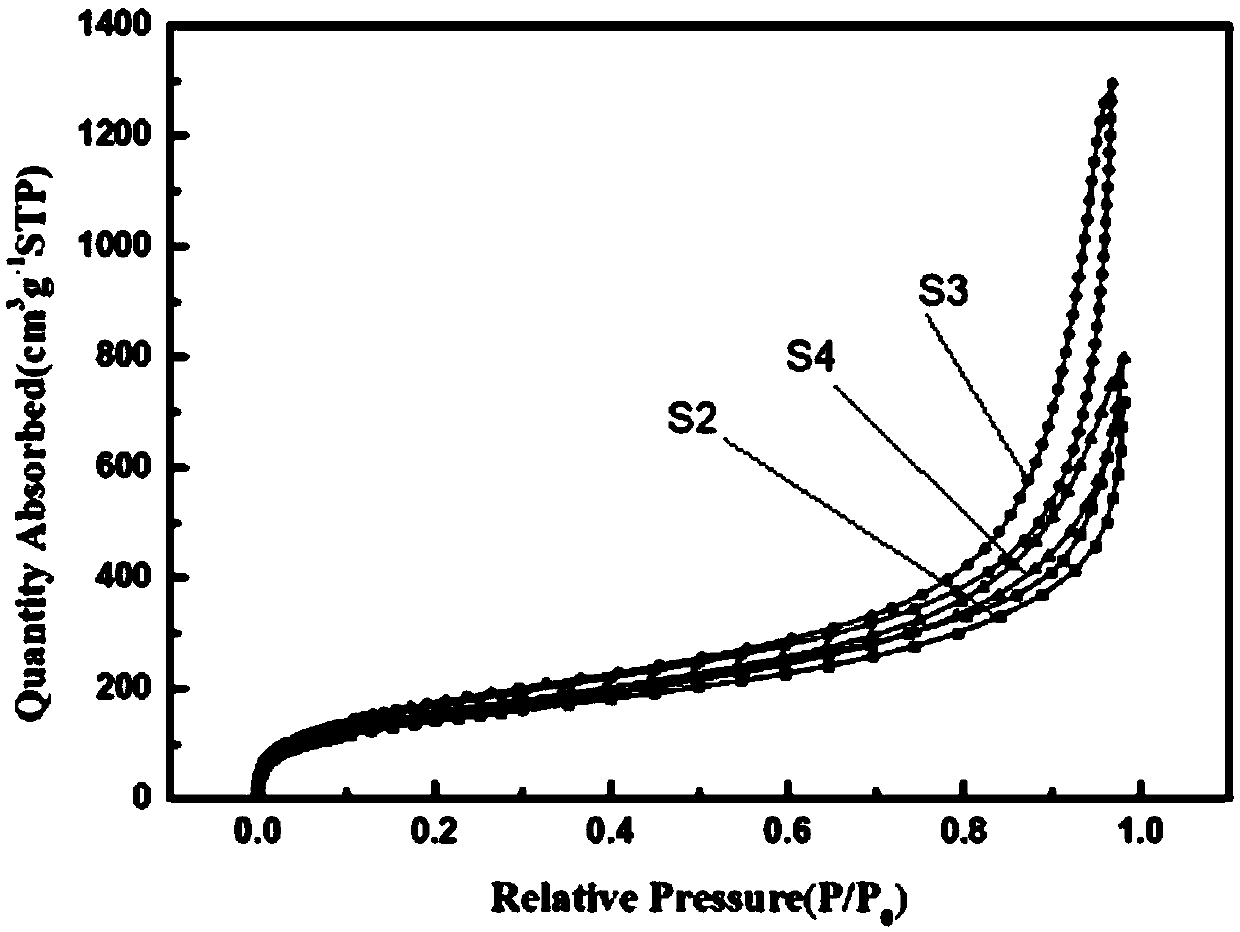

[0045] Preparation of zirconium-containing polyborosilazane (PBSN-TBZ) airgel:

[0046] Add PBSN (polyborosilazane) and TBZ (tetrabutyl zirconate) into a glass cup filled with tetrahydrofuran (THF) solvent in a mass ratio of 2:1, 3:1 and 4:1, respectively, and stir to obtain Homogenous precursor solution. Then, 0.6 g of divinylbenzene (DVB) was added into the homogeneous precursor solution to form a mixed transparent solution, and at the same time, the addition of solutes with different mass ratios ensured that the initial solvent volume concentration was 90%. The reaction mixture was stirred until homogeneous and transparent, then transferred to a polytetrafluoroethylene-lined reaction vessel and sealed. Finally, the reaction kettle was placed in an electric blast drying oven, the temperature was raised to 150° C. at a rate of 5° C. / min, and the temperature was maintained for 5 hours to complete the reaction. Then naturally cooled to room temperature to prepare a zirconium-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com