Rhenium sulfide nanotube, and preparation method and application thereof

A nanotube, rhenium sulfide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of flammability, high reaction temperature, and danger of lithium compounds, and achieve excellent electrochemical performance. The effect of performance, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

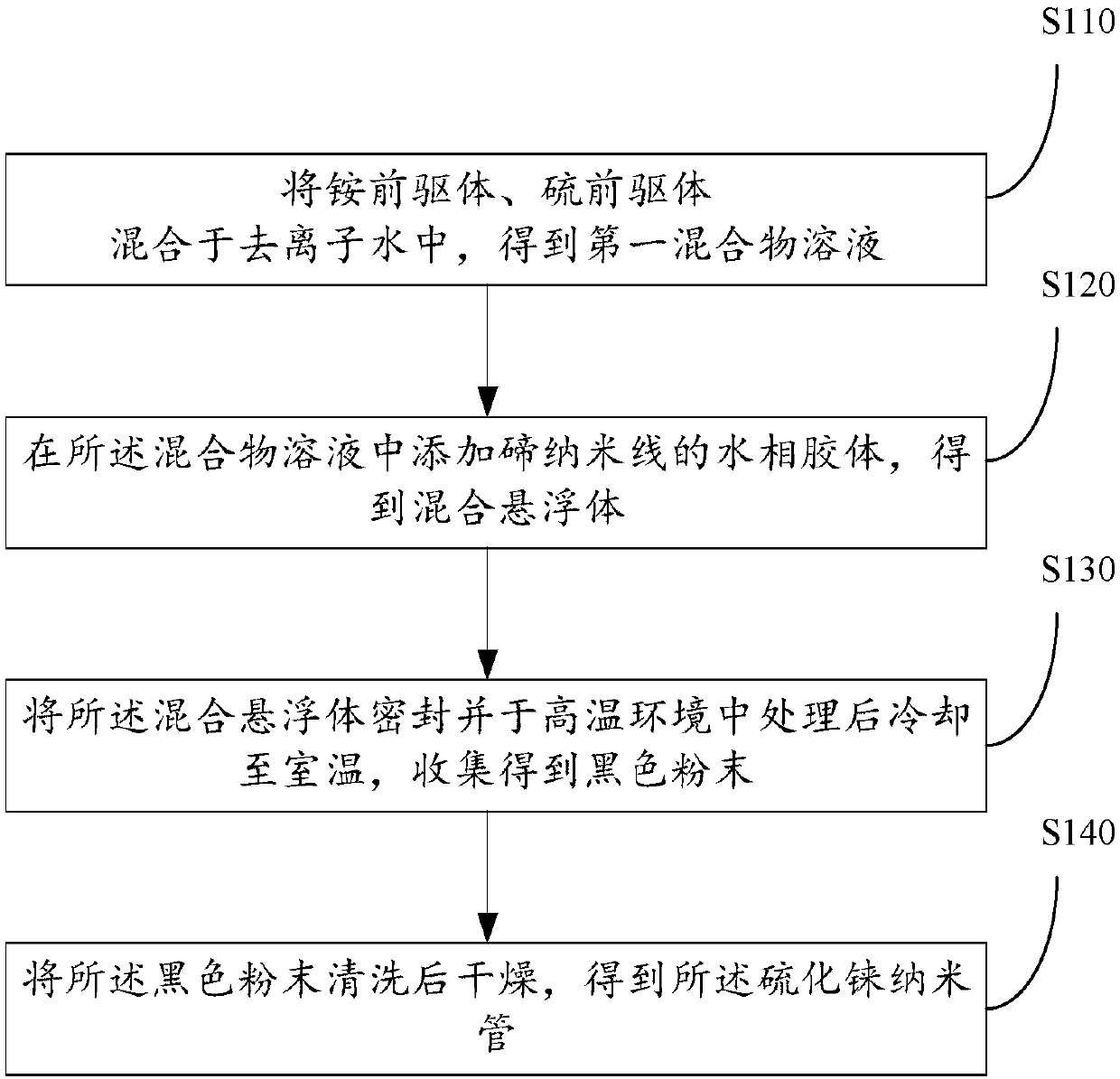

[0036] see figure 1 , a flow chart of the steps of the preparation method 10 of the rhenium sulfide nanotube provided in the embodiment of the present invention, comprising the following steps:

[0037] Step S110: mixing the rhenium precursor and the sulfur precursor in deionized water to obtain a first mixture solution.

[0038] In some preferred embodiments, the rhenium precursors include ammonium perrhenate, rhenium trichloride, rhenium pentachloride, potassium perrhenate, methyl rhenium trioxide, rhenium pentacarbonyl bromide, pentacarbonyl chloride At least one of rhenium chloride or dirhenium decacarbonyl.

[0039] In some preferred embodiments, the sulfur precursor is at least one of thiourea or thioacetamide.

[0040] In some preferred embodiments, the mass ratio of the rhenium precursor to the sulfur precursor is 1:(2-40).

[0041] Step S120: adding an aqueous phase colloid of tellurium nanowires to the mixture solution to obtain a mixed suspension;

[0042] see ...

Embodiment 1

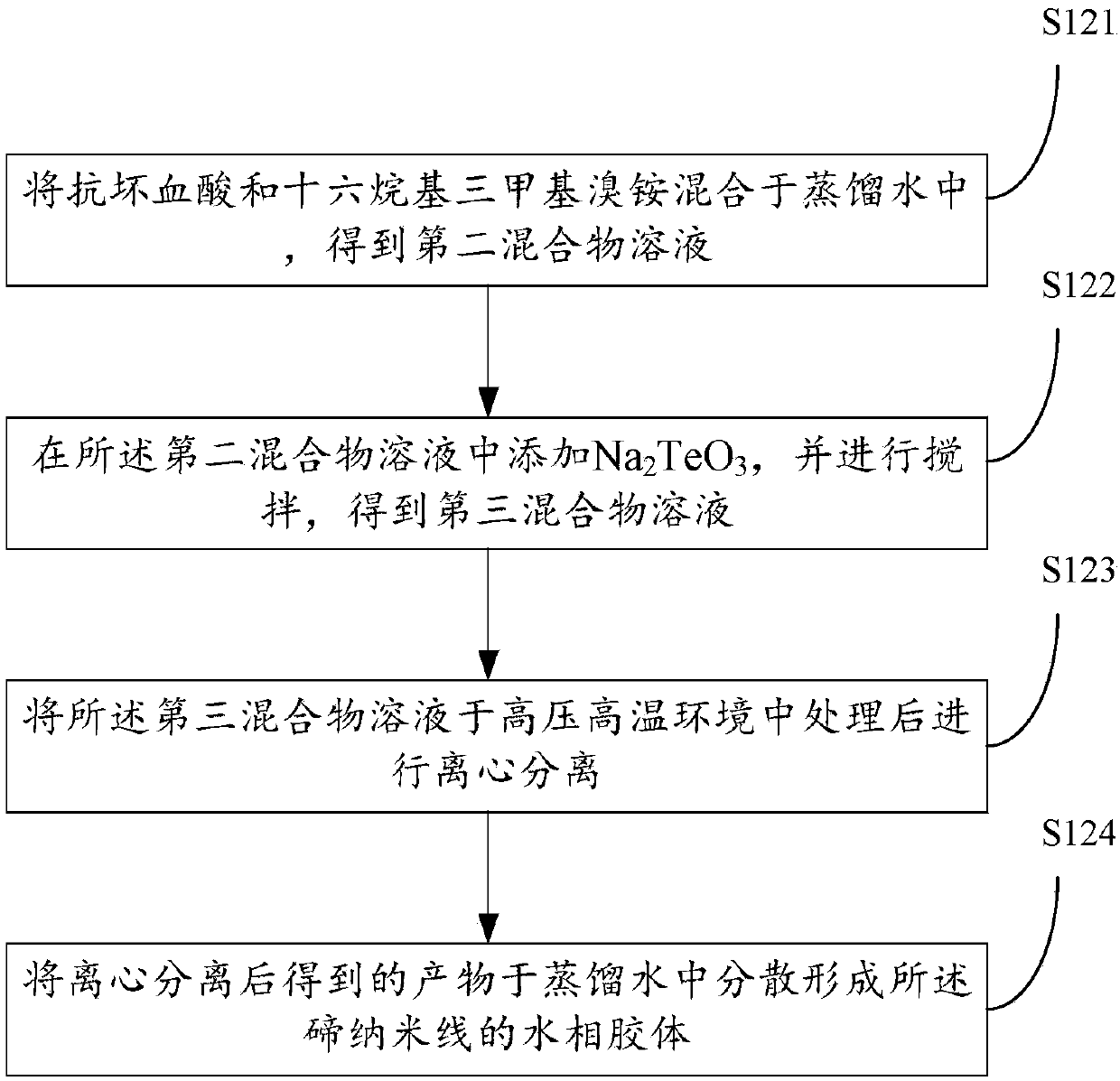

[0069] Preparation of Aqueous Colloids of Tellurium Nanowires

[0070] Mix ascorbic acid and cetyltrimethylammonium bromide with a mass ratio of 3:1 in distilled water to obtain a second mixture solution; add the second mixture solution to a glass beaker filled with 30 milliliters of distilled water, and then add 0.052 g Na 2 TeO 3 , and magnetically stirred for 30 minutes to obtain a third mixture solution, which was transferred to a 50 ml autoclave, and treated in an electric furnace at 70° C. for 24 hours, and then separated by centrifugal force for 10 minutes, and the centrifugal speed was 6000 rpm. The product obtained after centrifugation was dispersed in 10 ml of distilled water to form the aqueous phase colloid of the tellurium nanowires.

[0071] Preparation of rhenium sulfide nanotubes

[0072] Mix ammonium perrhenate and thiourea in deionized water at a mass ratio of 1:2 to obtain a first mixture solution; add an aqueous colloid of tellurium nanowires to the mixt...

Embodiment 2

[0074] Preparation of Aqueous Colloids of Tellurium Nanowires

[0075] Mix ascorbic acid and cetyltrimethylammonium bromide with a mass ratio of 20:1 in distilled water to obtain a second mixture solution; add the second mixture solution to a glass beaker filled with 30 milliliters of distilled water, and then add 0.052 g Na 2 TeO 3 , and carried out magnetic stirring for 30 minutes to obtain a third mixture solution, which was transferred to a 50 ml autoclave, and treated in an electric furnace at 10° C. for 24 hours, and then separated by centrifugal force for 10 minutes, and the centrifugal speed was 12000 rpm. The product obtained after centrifugation was dispersed in 10 ml of distilled water to form the aqueous phase colloid of the tellurium nanowires.

[0076] Preparation of rhenium sulfide nanotubes

[0077] Mix rhenium trichloride and thioacetamide in deionized water at a mass ratio of 1:40 to obtain a first mixture solution; add an aqueous phase colloid of telluriu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com