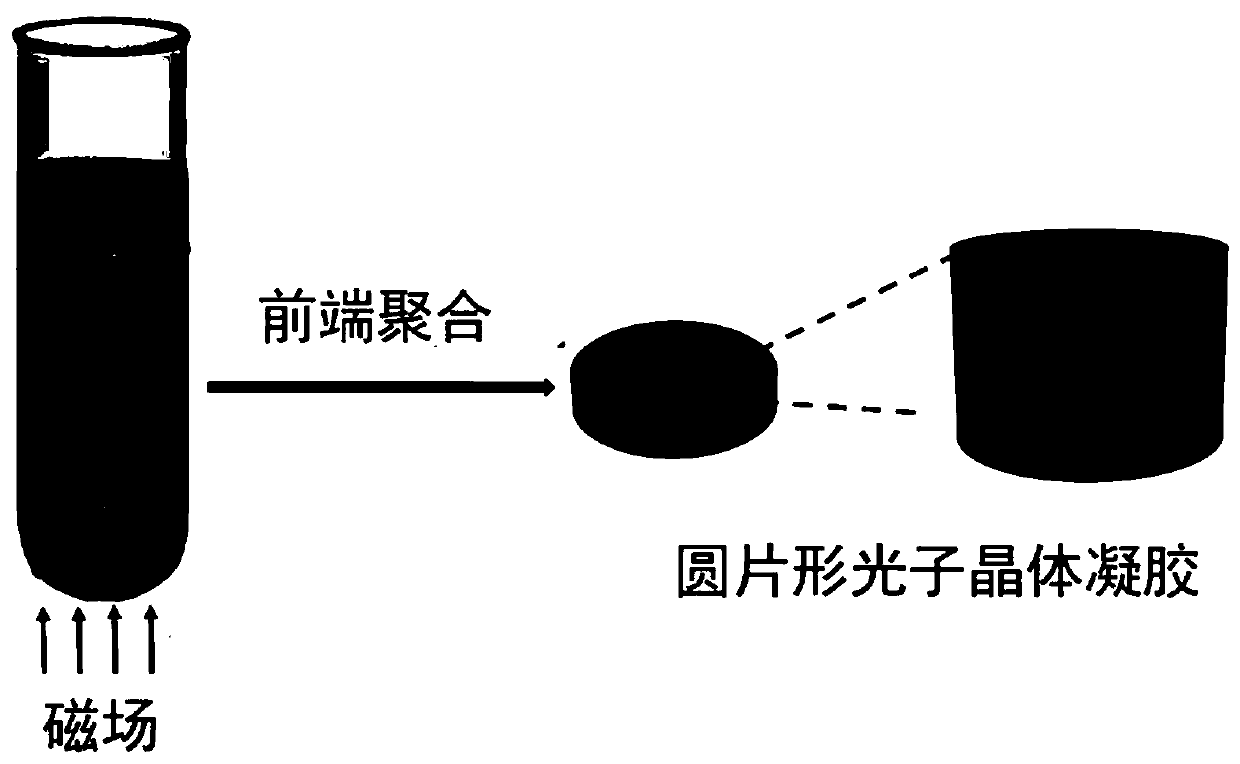

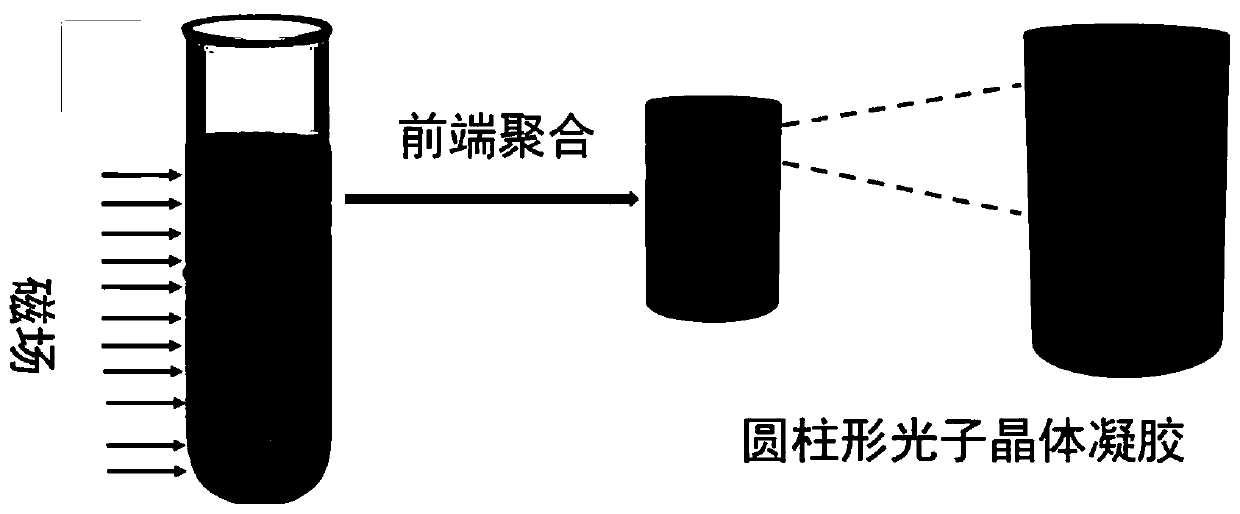

Method for preparing magnetic response photonic crystal gel through front-end polymerization

A technology of photonic crystals and front-end polymerization, applied in gel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of time-consuming, cumbersome steps, high energy consumption, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 0.54g of ferrocene was dissolved in 42.5g of acetone. After ultrasonic dispersion for 30 minutes, 1.7ml of hydrogen peroxide was slowly added dropwise. After magnetic stirring for 2h, the solution was transferred to the reactor, heated and maintained at 220°C. After 72 hours, the reaction kettle was naturally cooled to room temperature, magnetized separation and drying were collected to obtain magnetic ferroferric oxide nanoparticles with a particle size of 177nm, and 0.02g of magnetic particles with an average particle size of about 177nm were dispersed in 2g of N,N-dimethyl In the base formamide solvent, ultrasonically disperse until a uniform solution is obtained. Add 2.16g of methylol acrylamide, 1.44g of N-vinylcaprolactam, 0.5g of β-cyclodextrin, and ultrasonically disperse uniformly. Continue to add 0.1g initiator benzoyl peroxide and crosslinking agent N,N'- to the above solution. 0.2g methylene bisacrylamide, shake quickly and stir evenly. The final mixture is ...

Embodiment 2

[0028] 0.54 g of ferrocene was dissolved in 42.5 g of acetone, and after ultrasonic dispersion for 30 minutes, 1.4 ml of hydrogen peroxide was slowly added dropwise, and after magnetic stirring for 2 hours, the solution was transferred to the reactor, heated and maintained at 230°C. After 60 hours, the reaction kettle was naturally cooled to room temperature, magnetic separation and drying were collected to obtain magnetic ferroferric oxide nanoparticles with a particle size of 135 nm, and 0.03 g of magnetic particles with an average particle size of about 135 nm were dispersed in 2.5 g of dimethyl sulfoxide. In the solvent, ultrasonic dispersion until a homogeneous solution is obtained. Add 2g of N,N-dimethylacrylamide, 1g of N-vinylcaprolactam, 0.6g of β-cyclodextrin, ultrasonic dispersion, continue to add the initiator 0.05g of azobisisobutyronitrile, crosslinker diethylene 0.08g of base benzene, shake quickly and stir evenly. The final mixed solution was transferred to a t...

Embodiment 3

[0030] 0.54g of ferrocene was dissolved in 42.5g of acetone, and after ultrasonic dispersion for 30 minutes, 2.1ml of hydrogen peroxide was slowly added dropwise, and after magnetic stirring for 2h, the solution was transferred to the reactor, heated and maintained at 200°C. After 80h, the reaction kettle was naturally cooled to room temperature, magnetic separation and drying were collected to obtain magnetic ferroferric oxide nanoparticles with a particle size of 215nm, and 0.02g magnetic particles with an average particle size of about 215nm were dispersed in 2.2g 1-methyl- Disperse ultrasonically in 2-pyrrolidone solvent until a uniform solution is obtained. Add 1.4g of acrylamide, 0.4g of N-isopropylacrylamide, 0.4g of β-cyclodextrin, and ultrasonically disperse uniformly. Continue the above solution to add 0.1g of initiator azobisisoheptonitrile and crosslinker of dimethacrylic acid. The ethanol ester 0.05g is quickly shaken and stirred evenly. The final mixed solution w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com