A kind of method of gravity separation of gibbsite type bauxite

A gibbsite type and bauxite technology, applied in the direction of solid separation, etc., can solve the problems of a large number of flotation reagents, complicated process, difficult to use, etc., achieve good sustainable development, widen source channels, and high comprehensive utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) After crushing 1t of gibbsite-type bauxite 1, send it into the ball mill, and the filling rate of steel balls is 28% (mass percentage of steel balls: large ball Ф80mm: 20%, medium ball Ф55mm: 60% , small ball Ф35mm: 20%), carry out dry grinding until the mass content of particle size ≤ 74 μm is 64.56%, the mass content of particle size ≤ 10 μm is 17.12%, and the monomer dissociation degree of each mineral is 72%. Mineral powder;

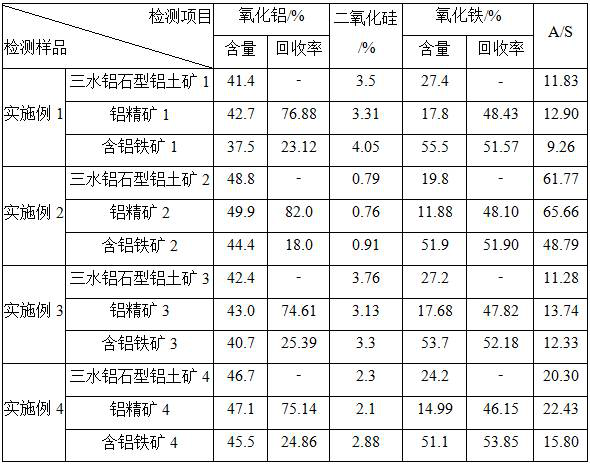

[0041] (2) Slurry the mineral powder obtained in step (1) with sodium aluminate solution until the mass concentration of the pulp is 10%, and then send it into the jig machine, and perform wet grinding at 25°C, with a stroke of 15mm and a stroke frequency of 120 times / min. After gravity separation, 0.745t (dry basis) aluminum concentrate 1 and 0.255t (dry basis) aluminum-bearing iron ore 1 were obtained respectively (the main components are shown in Table 1).

[0042] The process of wet gravity separation in step (2) is roughing, sweeping...

Embodiment 2

[0044] (1) After crushing 1t of gibbsite-type bauxite 2, send it to the rod mill, and the steel rod filling rate is 25% (mass percentage of steel rod: Ф70mm: 60%, Ф60mm: 40%), Carry out dry grinding until the mass content of the particle size ≤ 74 μm is 72.3%, the mass content of the particle size ≤ 10 μm is 28.35%, and the monomer dissociation degree of each mineral is 88%, and the ore powder is obtained;

[0045] (2) Slurry the mineral powder obtained in step (1) with water until the mass concentration of the pulp is 8%, send it to a shaker, and carry out wet gravity separation at 20°C, with a stroke of 10mm and a stroke frequency of 160 times / min. 0.802t (dry basis) aluminum concentrate 2 and 0.198t (dry basis) aluminum-bearing iron ore 2 were obtained respectively (the main components are shown in Table 1).

[0046] The process of wet gravity separation in step (2) is roughing, sweeping and refining, and the middlings obtained from sweeping and refining are returned in seq...

Embodiment 3

[0048] (1) After crushing 1t of gibbsite-type bauxite 3, send it to the rod mill, and the steel rod filling rate is 27% (the mass percentage of the steel rod is: Ф70mm: 40%, Ф60mm: 50%, Ф50mm : 10%), carry out dry grinding until the mass content of the particle size ≤ 74 μm is 76.0%, the mass content of the particle size ≤ 10 μm is 24.63%, and the monomer dissociation degree of each mineral is 79%, and the ore powder is obtained;

[0049] (2) Send the ore powder obtained in step (1) into the cyclone separator, under the wind pressure of 0.15MPa and the feed concentration of 4.0kg / m 3 Next, after dry gravity separation, 0.736t (dry basis) aluminum concentrate 3 and 0.264t (dry basis) aluminum-containing iron ore 3 were obtained respectively (the main components are shown in Table 1).

[0050] The process of the dry re-selection in step (2) is roughing, sweeping and concentrating, and the middlings obtained from the sweeping and concentrating are concentrated and returned to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com