Gallium nitride HEMT device structure and preparation method thereof

A device structure and gallium nitride technology, applied in the field of microelectronics, can solve the problems of device performance degradation and reliability, and achieve the effects of simple manufacturing process, high breakdown voltage resistance and high breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

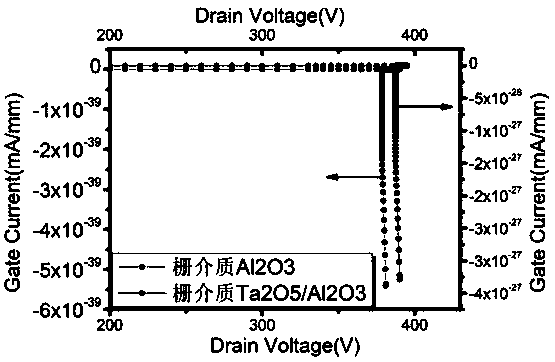

Problems solved by technology

Method used

Image

Examples

Embodiment 1

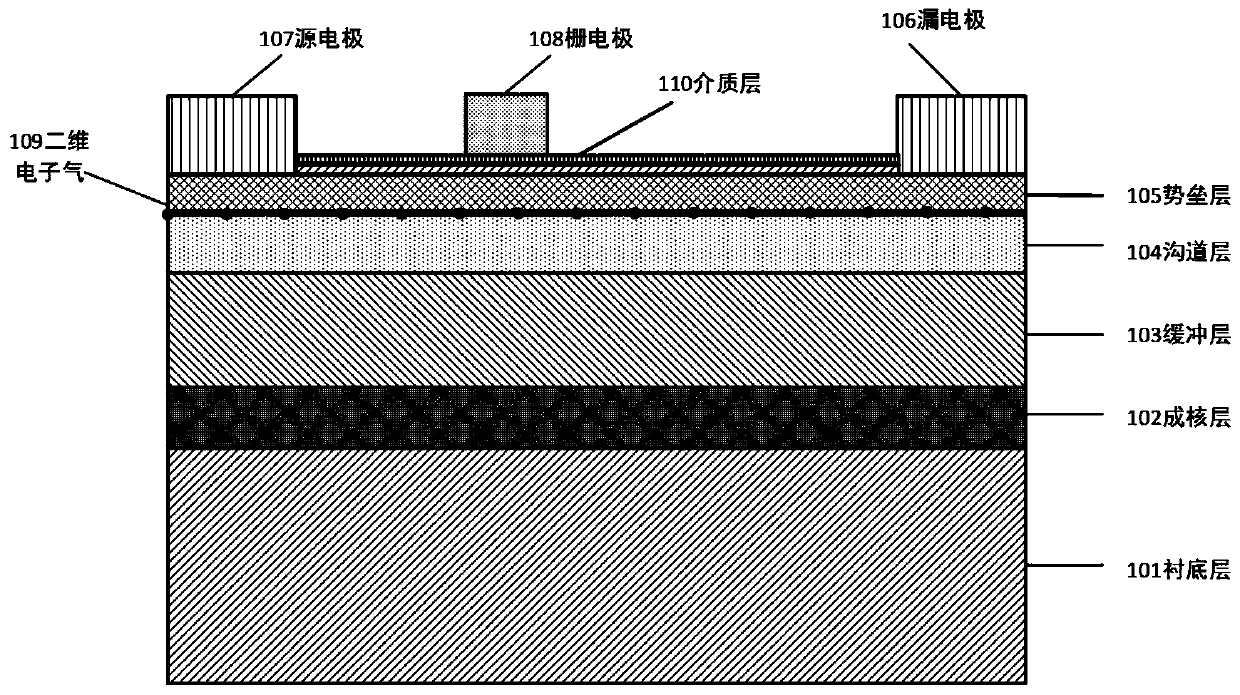

[0033] 1. Use MOCVD technology and equipment to carry out AlGaN / GaN heterojunction epitaxy on a 6-inch substrate (insulating or semi-insulating sapphire, silicon, silicon carbide, gallium nitride, zinc oxide, and diamond, etc.). This technology is a general conventional technology. The AlGaN / GaN heterojunction structure sequentially includes a gallium nitride (GaN) buffer layer 103, a low-temperature gallium nitride (GaN) nucleation layer 102, a gallium nitride (GaN) channel layer 104, an aluminum Gallium nitride (AlGaN) barrier functional layer 105 and a channel 109 of high-concentration two-dimensional electron gas (2DEG) formed at the interface.

[0034] 2. Deposit Ta on the surface of the above-mentioned AlGaN / GaN heterojunction material by atomic layer deposition (ALD) 2 o 5 Thin film layer with Al 2 o 3 The thin film layer is used as a dielectric layer with a thickness of 50nm.

[0035] 3. Organically clean the material obtained in the previous step. After cleaning, ...

Embodiment 2

[0040] 1. Use MOCVD technology and equipment to carry out AlGaN / GaN heterojunction epitaxy on a 6-inch substrate (insulating or semi-insulating sapphire, silicon, silicon carbide, gallium nitride, zinc oxide, and diamond, etc.). This technology is a general conventional technology. The AlGaN / GaN heterojunction structure sequentially includes a gallium nitride (GaN) buffer layer 103, a low-temperature gallium nitride (GaN) nucleation layer 102, a gallium nitride (GaN) channel layer 104, an aluminum Gallium nitride (AlGaN) barrier functional layer 105 and a channel 109 of high-concentration two-dimensional electron gas (2DEG) formed at the interface.

[0041] 2. Deposit Ta on the surface of the above-mentioned AlGaN / GaN heterojunction material by atomic layer deposition (ALD) 2 o 5 Thin film layer with Al 2 o 3 The thin film layer is used as a dielectric layer with a thickness of 100nm.

[0042] 3. Organically clean the material obtained in the previous step. After cleaning,...

Embodiment 3

[0047] 1. Use MOCVD technology and equipment to carry out AlGaN / GaN heterojunction epitaxy on a 6-inch substrate (insulating or semi-insulating sapphire, silicon, silicon carbide, gallium nitride, zinc oxide, and diamond, etc.). This technology is a general conventional technology. The AlGaN / GaN heterojunction structure sequentially includes a gallium nitride (GaN) buffer layer 103, a low-temperature gallium nitride (GaN) nucleation layer 102, a gallium nitride (GaN) channel layer 104, an aluminum Gallium nitride (AlGaN) barrier functional layer 105 and a channel 109 of high-concentration two-dimensional electron gas (2DEG) formed at the interface.

[0048] 2. Deposit Ta on the surface of the above-mentioned AlGaN / GaN heterojunction material by atomic layer deposition (ALD) 2 o 5 Thin film layer with Al 2 o 3 The thin film layer is used as a dielectric layer with a thickness of 150nm.

[0049] 3. Organically clean the material obtained in the previous step. After cleaning,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com