Preparation method of MoS2-modified three-dimensional porous carbon-based composite material for electro-catalytic hydrogen evolution

A carbon-based composite material and three-dimensional porous technology, applied in the field of nanomaterials, can solve the problems of inability to obtain a three-dimensional self-supporting structure, high risk factor, cumbersome steps, etc., to improve electrochemical conductivity and catalytic activity, and high-efficiency hydrogen evolution performance , the effect of high specific surface area and roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A MoS for electrocatalytic hydrogen evolution 2 A method for preparing a modified three-dimensional porous carbon-based composite material, the specific steps are as follows:

[0054] (1) Add 0.5mmol of ammonium tetrathiomolybdate powder to 60mL of deionized water, and ultrasonically react at room temperature (power 400W, frequency 40kHz) for 2 hours to obtain a uniformly dispersed suspension;

[0055] (2) Cut the carbon fiber felt into a size of 1×1×0.5cm -2 , followed by ethanol and deionized water with 5000rpm rotation number centrifugal washing for 30 minutes, and natural drying, to remove organic impurities therein;

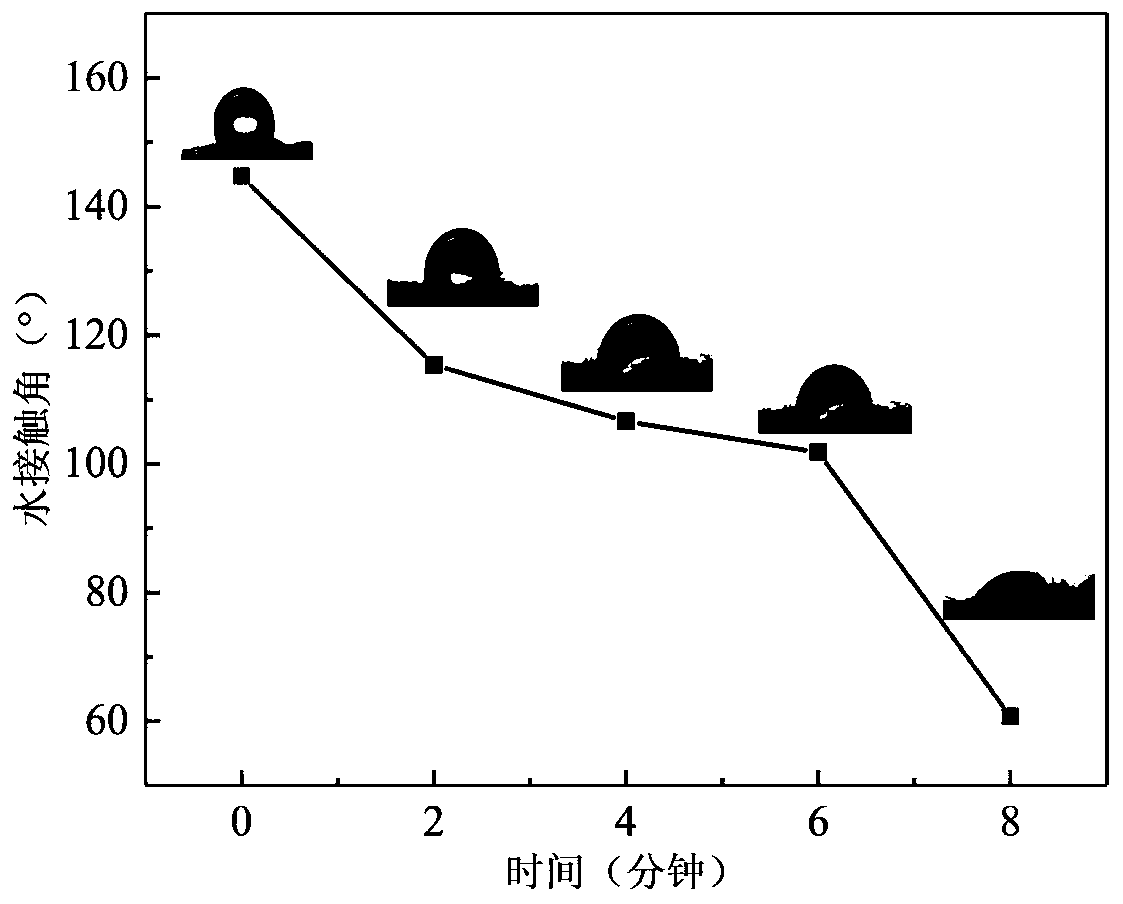

[0056] (3) The obtained carbon fiber mat is subjected to ultraviolet ozone treatment for more than 8 minutes, so that it is completely in a hydrophilic state, so as to ensure that the carbon fiber mat can be fully contacted with the precursor solution;

[0057] Among them, the above-mentioned ultraviolet and ozone treatment conditions are to use an ...

Embodiment 2

[0068] A MoS for electrocatalytic hydrogen evolution 2 A method for preparing a modified three-dimensional porous carbon-based composite material, the specific steps are as follows:

[0069] (1) Add 60 mg of ammonium tetrathiomolybdate powder into 11 mL of N, N-dimethylformamide (DMF) solvent, and obtain a uniformly dispersed suspension through stirring and ultrasonic treatment for 1 hour respectively;

[0070] (2) Configure 6 mL of graphene oxide with a concentration of 3.5 mg / mL, drop it into the above-mentioned ammonium tetrathiomolybdate suspension and stir at room temperature for 1 hour, and ultrasonically (power is 400W, frequency is 40kHz) for 1 hour to obtain mixture;

[0071] (3) Add 10 mmol of urea to the resulting mixed solution, stir for 15 minutes, transfer to the reaction kettle, and keep at 200° C. for 10 hours;

[0072] (4) After the reaction, the resulting black product was soaked in an aqueous solution containing 10-15% alcohol for more than 24 hours, and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com