Ozone room temperature decomposition honeycomb module and preparation method thereof

A honeycomb, room temperature technology, applied in the field of ozone room temperature decomposition honeycomb modules and their preparation, can solve the problems of high energy consumption and large wind resistance, and achieve the effects of long running time, small wind resistance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

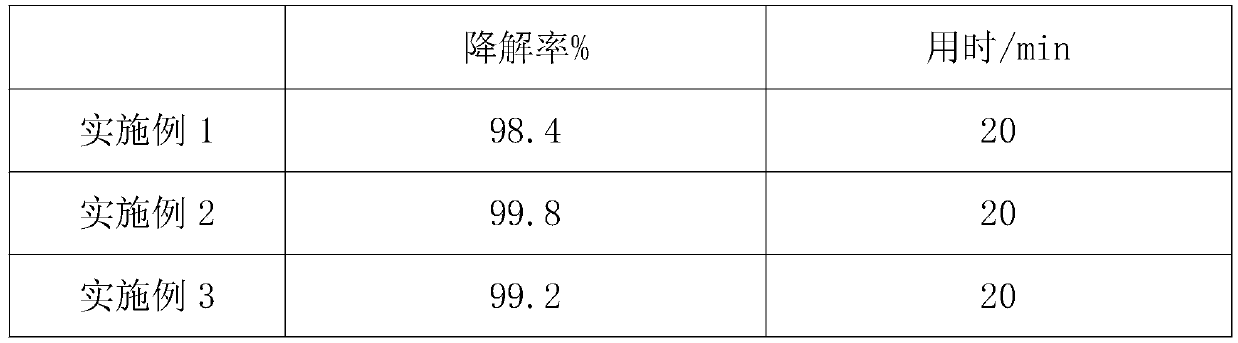

Embodiment 1

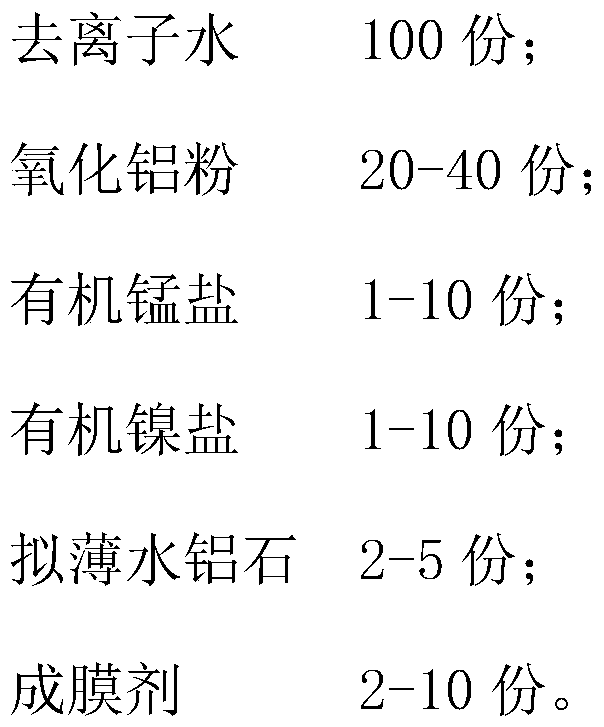

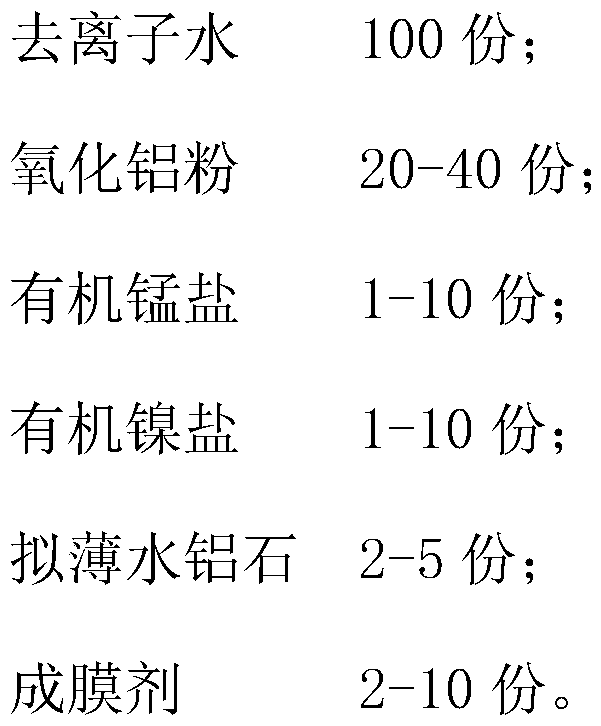

[0032] A preparation method for ozone room temperature decomposition honeycomb module, comprising the following steps:

[0033] 1) Weigh 1000g deionized water, 300gγ-Al 2 o 3 , 16.9g Mn(CH 3 COO) 2 4H 2 O, 20.0g Ni(CH 3 COO) 2 4H 2 0. 20g pseudo-boehmite, 30g film-forming agent (1.5g polyvinyl alcohol, 3.0g phosphoric acid, 10.5g aluminum sol, 15g acrylic resin emulsion) are poured into the mixing bucket, and the lifting mixer head is opened and mixed for 30min at 600rpm, Then use a lifting high-speed shearing emulsifier at 8000 rpm to homogenize the mixture for 60 minutes to obtain the catalyst slurry;

[0034] 2) Catalyst slurry spraying: Insert the inlet pipe of the slurry pump into the catalyst slurry bucket, connect the outlet pipe with the material pipe of the spray gun, connect the air source of the spray gun to the compressed air tank, hang the nozzle of the spray gun on the fixed frame above the conveyor belt, and place the aluminum The honeycomb is laid flat ...

Embodiment 2

[0040] A preparation method for ozone room temperature decomposition honeycomb module, comprising the following steps:

[0041] 1) Weigh 1000g deionized water, 250gγ-Al 2 o 3 , 15.4g MnC 2 o 4 2H 2 O, 25.0gNi(CH 3 COO) 2 4H 2 0, 25g pseudo-boehmite, 30g film-forming agent (1.5g polyvinyl alcohol, 3.0g phosphoric acid, 10.5g aluminum sol, 15g acrylic resin emulsion) are poured in the mixing bucket, open the lifting mixer head and mix 30min with 500rpm, Then use a lifting high-speed shearing emulsifier at 7000rpm to homogenize the mixture for 60 minutes to obtain the catalyst slurry;

[0042] 2) Catalyst slurry spraying: Insert the inlet pipe of the slurry pump into the catalyst slurry bucket, connect the outlet pipe with the material pipe of the spray gun, connect the air source of the spray gun to the compressed air tank, hang the nozzle of the spray gun on the fixed frame above the conveyor belt, and place the aluminum The honeycomb is laid flat on the conveyor belt, ...

Embodiment 3

[0048] A preparation method for ozone room temperature decomposition honeycomb module, comprising the following steps:

[0049] 1) Weigh 1000g of deionized water and 350g of γ-Al 2 o 3 , 28.8g MnC 2 o 4 2H 2 O, 17.3g Ni 3 (C 6 h 5 o 7 ) 2 , 30g pseudo-boehmite, 35g film-forming agent (1.8g polyvinyl alcohol, 3.5g phosphoric acid, 12.2g aluminum sol, 17.5g acrylic resin emulsion) are poured into the mixing bucket, and the lifting mixer head is turned on and mixed at 700rpm for 30min. Then use a lifting high-speed shearing emulsifier at 8000 rpm to homogenize the mixture for 60 minutes to obtain the catalyst slurry;

[0050] 2) Catalyst slurry spraying: Insert the inlet pipe of the slurry pump into the catalyst slurry bucket, connect the outlet pipe with the material pipe of the spray gun, connect the air source of the spray gun to the compressed air tank, hang the nozzle of the spray gun on the fixed frame above the conveyor belt, and place the aluminum The honeycomb ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com