Preparation method and application of biochar-loaded nano zero-valent iron sulfide material

A zero-valent iron and biochar technology, applied in chemical instruments and methods, physical/chemical process catalysts, water pollutants, etc., can solve the problems of reduced reaction rate, reduced flow performance, and reduced specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of biochar-loaded nanometer zero-valent iron sulfide material, comprising the following steps:

[0029] Under vacuum or inert atmosphere, the biomass and FeSO 4 The solutions were mixed, evaporated to dryness, ground, and dried to obtain the loaded FeSO 4 biomass;

[0030] The loaded FeSO 4 The biomass is pyrolyzed at 800-1000°C under an inert atmosphere to obtain biochar-supported nano-zero-valent iron sulfide materials.

[0031] Compared with the prior art, the present invention adopts the one-pot pyrolysis method to prepare the biochar-loaded nano-sulfurized zero-valent iron material, without adding additional chemical reduction reagents and vulcanization reagents, and achieves simultaneous biochar reduction of zero-valent iron. The purpose of loading and vulcanization modification is simple, and the prepared material can quickly and effectively treat sewage containing halogenated organic matter.

[0032] In the present...

Embodiment 1

[0044] 1.1 Raw material pretreatment: pulverize the sawdust, sieve, keep the 100-200 mesh sieved sawdust, and dry it at 80°C for later use.

[0045] 1.2 Add 5mmol FeSO 4 ·7H 2 O. 5g of sawdust treated in 1.1 and 200ml of deoxygenated water were mixed and dispersed under the assistance of ultrasound, then the mixed solution was transferred to a flask, deoxygenated with nitrogen for 30min, shaken at 180r / m in a water bath shaker at 25°C for 12h, and then used The moisture in the flask was evaporated to dryness by a rotary evaporator, and the solid composite was dried in a vacuum drying oven at 80° C., and after uniform grinding, the biomass loaded with ferrous sulfate was obtained.

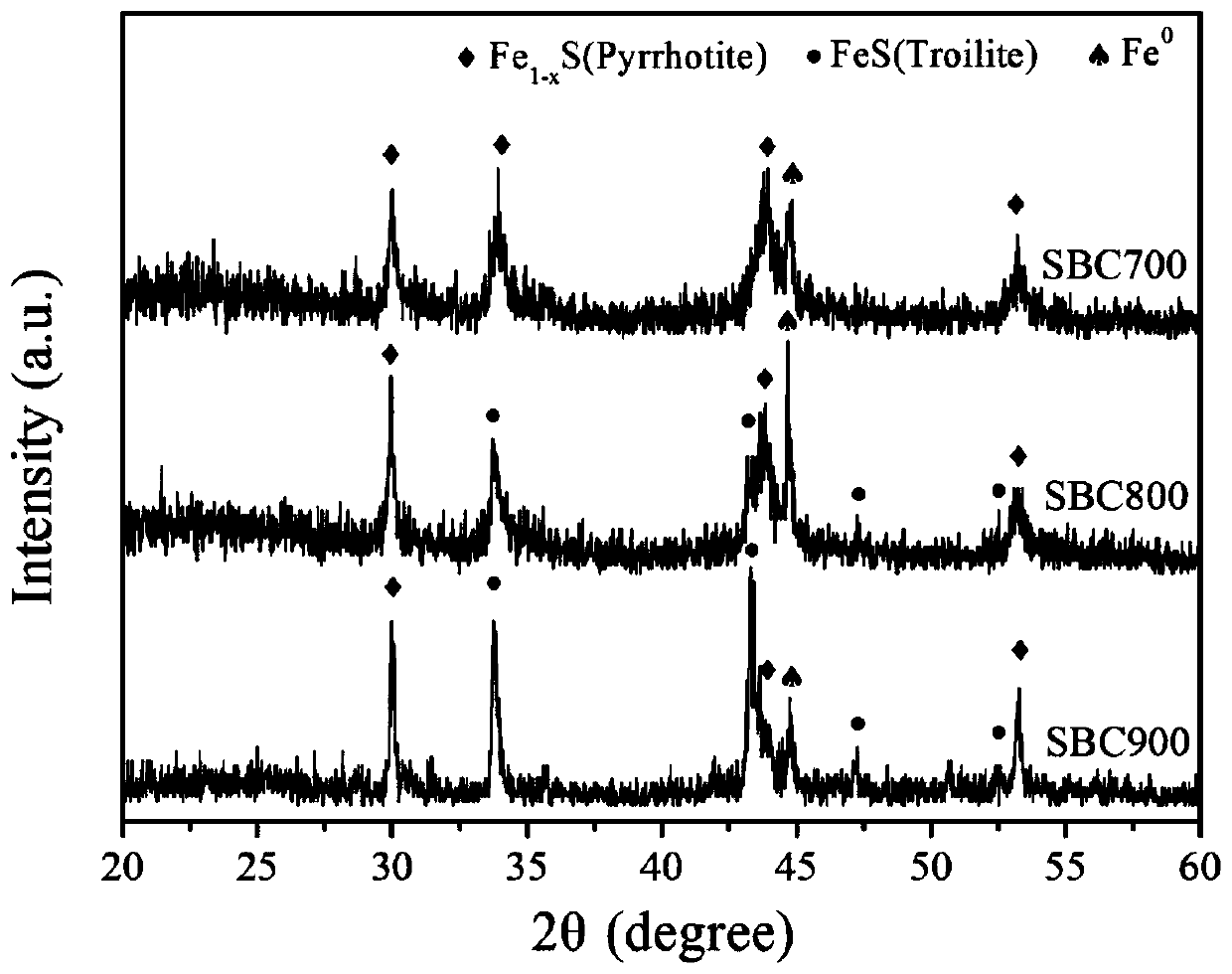

[0046] 1.3 Under a nitrogen atmosphere, use a rapid pyrolysis furnace to rapidly pyrolyze 2 g of the above-mentioned sawdust loaded with ferrous sulfate at 800 ° C for 1 hour to obtain biochar-supported nano-zero-valent iron sulfide (SBC-800) .

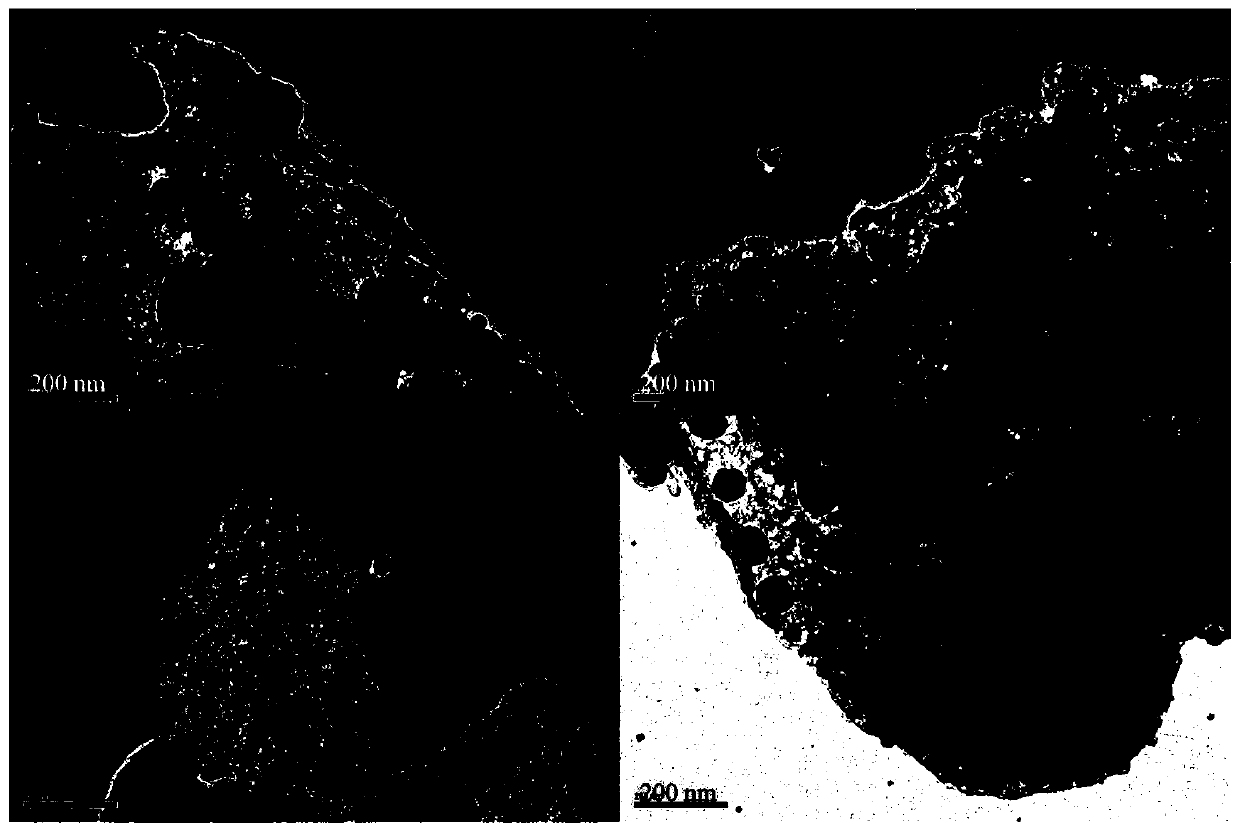

[0047] figure 1 It is the TEM figure of the bioch...

Embodiment 2

[0050] 1.1 Raw material pretreatment: pulverize the sawdust, sieve, keep the 100-200 mesh sieved sawdust, and dry it at 80°C for later use.

[0051] 1.2 Add 5mmol FeSO 4 ·7H 2 O. 5g of sawdust treated in 1.1 and 200ml of deoxygenated water were mixed and dispersed under the assistance of ultrasound, then the mixed solution was transferred to a flask, deoxygenated with nitrogen for 30min, shaken at 180r / m in a water bath shaker at 25°C for 12h, and then used The moisture in the flask was evaporated to dryness by a rotary evaporator, and the solid composite was dried in a vacuum drying oven at 80° C., and after uniform grinding, the biomass loaded with ferrous sulfate was obtained.

[0052] 1.3 Under a nitrogen atmosphere, use a rapid pyrolysis furnace to rapidly pyrolyze 2 g of the above-mentioned sawdust loaded with ferrous sulfate at 900 ° C for 1 hour to obtain biochar-supported nano-zero-valent iron sulfide (SBC-900) .

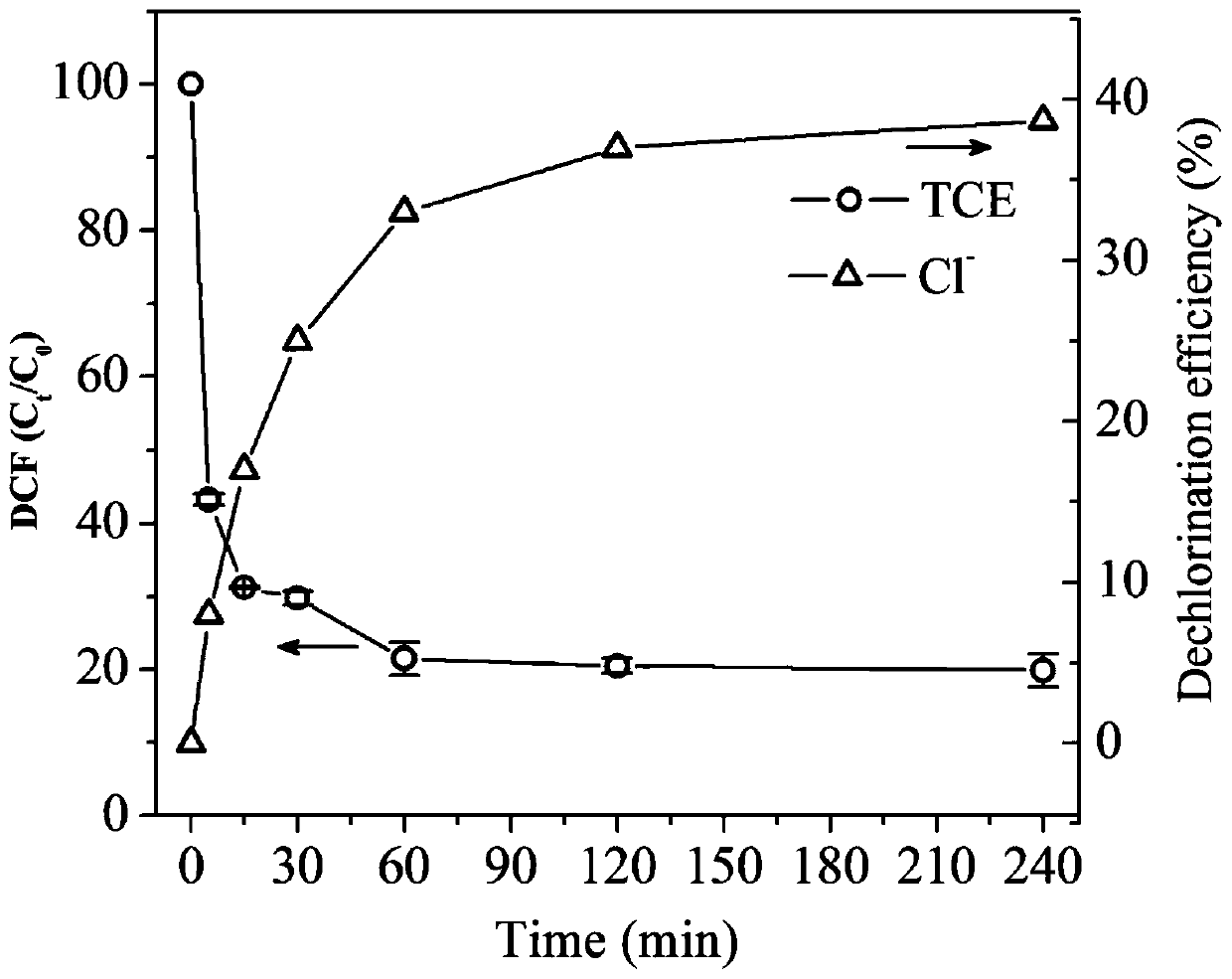

[0053] Biochar-loaded nano-zero-valent iron sulfid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com