Preparation method of cyanoacrylate ultraviolet light absorber

A technology of cyanoacrylic acid and ultraviolet rays, which is applied in the preparation of carboxylic acid nitrile, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of difficult recycling, large environmental pollution, and low product yield, and achieve convenient post-processing, The effect of high product yield and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

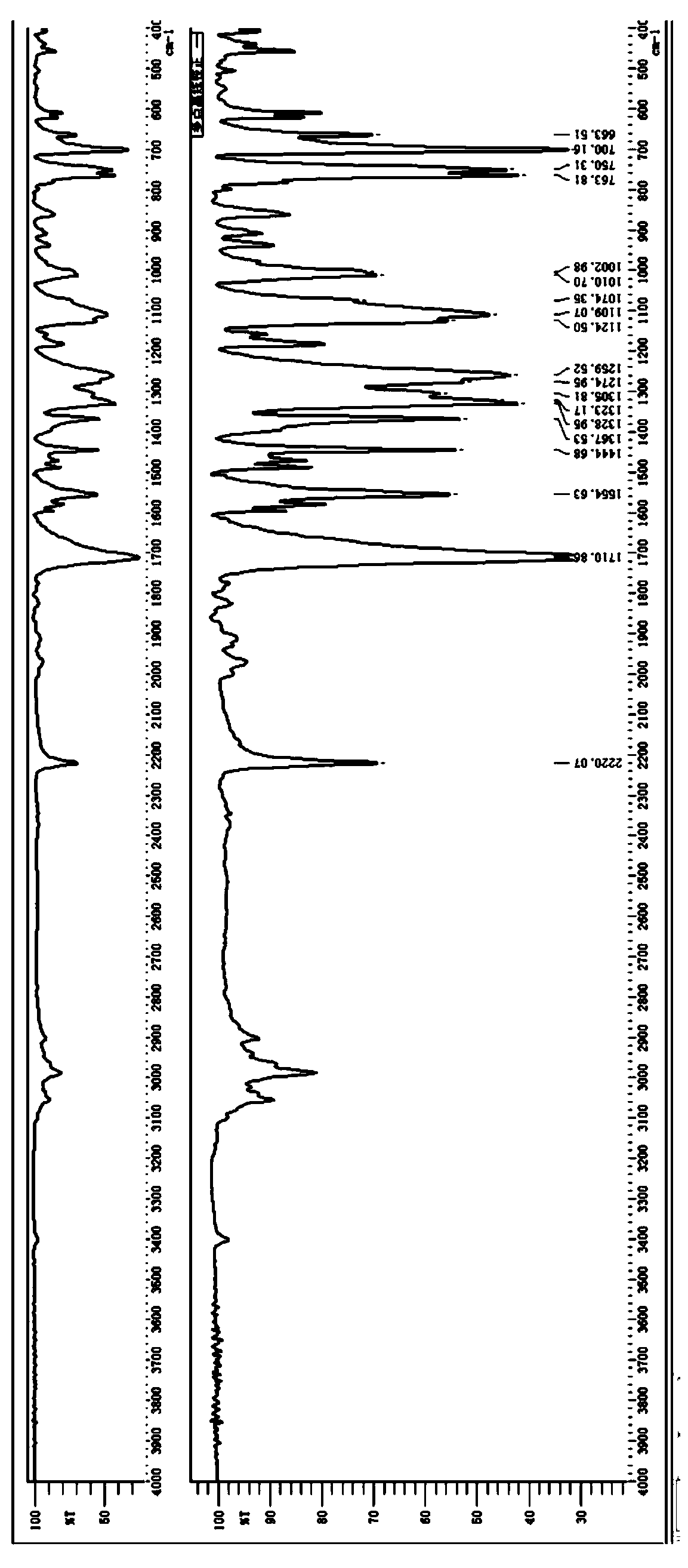

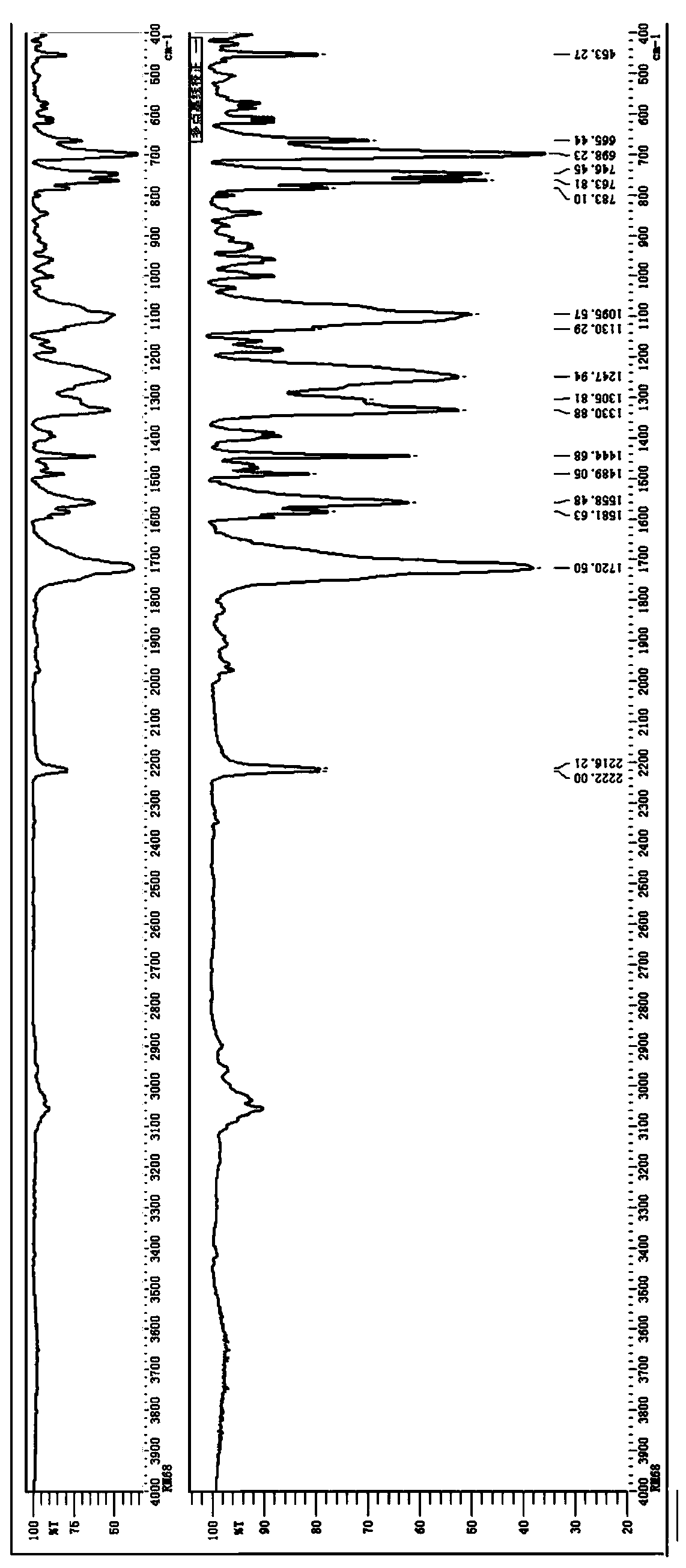

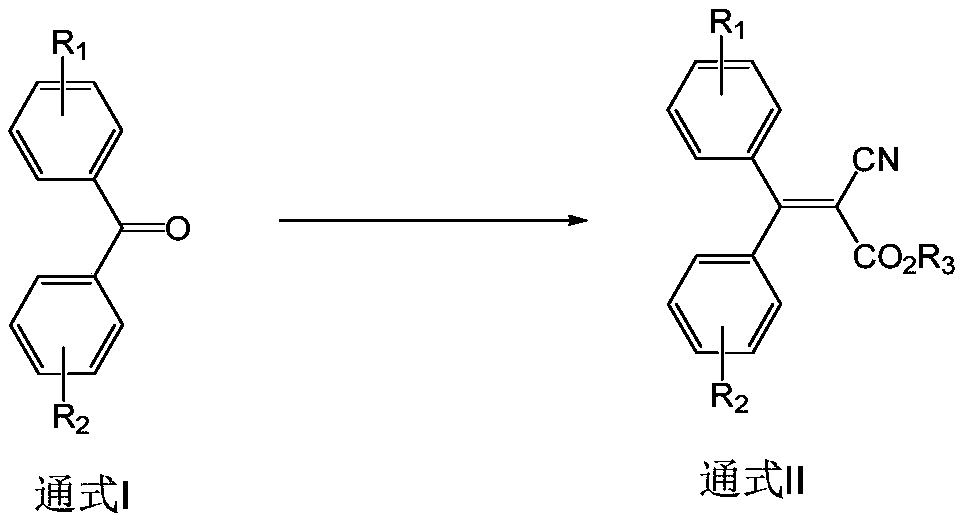

[0043] A kind of preparation method of cyanoacrylate ultraviolet absorber, the benzophenone compound shown in general formula I, and cyanoacetate, under weak alkaline condition, take the acidic ionic liquid of gac grafting as Catalyst reacts and generates general formula II compound;

[0044]

[0045] Among them, R 1 , R 2 each independently selected from one of H or halogen, R 3 is methyl or ethyl.

[0046] This reaction belongs to the Knoevenagel condensation reaction, that is, under the catalysis of a weak base (amine, pyridine, etc.), benzophenone is condensed with a cyanoacetate having an active α-hydrogen atom.

[0047] In the present invention, the acidic ionic liquid grafted with activated carbon is compound D, and the structural formula of D is:

[0048]

[0049] where n is any integer from 2 to 6, X - for HSO 4 - or CH 3 COO - ; is activated carbon;

[0050] R is C 1-20 Alkyl or its corresponding haloalkyl, preferably C 1-4 The alkyl, and its corr...

Embodiment 1

[0087] The preparation of the catalyst 1 of embodiment 1 activated carbon grafting acidic ionic liquid

[0088] Add 10g of commercially available powdered coconut shell activated carbon (specific surface area 1200, ash content 1%) into a 250mL four-neck flask, then add 50mlTHF, put it on a magnetic stirrer and start stirring, then add 2g of caustic soda, then add 10g of dichloroethylene After soaking in alkanes for 5 hours, filter, dry at 105°C for 4 hours, then add it into a 250mL four-neck flask, add 100ml of acetonitrile, start stirring on a magnetic stirrer, add 8g of butylimidazole dropwise at room temperature, then raise the temperature and reflux for 10h, and then Cool to 30°C, filter, then dry, then add the dried product into a 250mL four-neck flask, add 100ml of acetone, start stirring on a magnetic stirrer, then add 5g of sodium bisulfate, stir at room temperature for 4h, filter, and dry the filter cake , namely the catalyst 1 of activated carbon grafted with acidic ...

Embodiment 2

[0089] The preparation of the catalyst 2 of embodiment 2 activated carbon grafting acidic ionic liquid

[0090] Proceed according to the scheme in implementation 2, change dichloroethane into dichloropropane, and the rest of the preparation method is the same as in Example 1, to obtain catalyst 2 of activated carbon grafted acidic ionic liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com