Production process of full-enzyme polypeptide for fertilizer

A production process, the whole enzyme technology, applied in the direction of using electricity/wave energy to treat microorganisms, enzymes, nitrogen fertilizers, etc., can solve the problems of high production cost, destruction or absorption, weak operability, etc., and achieve a wide range of reaction pH and temperature, The effect of preventing the reduction of polypeptide activity and preventing protein denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of production technology of whole enzyme polypeptide for fertilizer, comprises the following steps:

[0031] 1) Current-assisted swelling: the protein was placed in the swelling solution, treated with a constant voltage forward current for 18 minutes, and then treated with a constant voltage reverse current for 15 minutes;

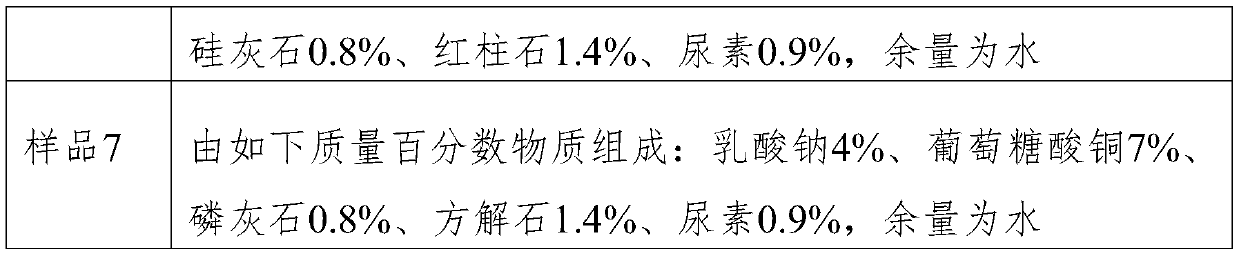

[0032] 2) Ultrasound-assisted enzymolysis: add 0.5% of its mass activated compound enzyme preparation to the result of step 1) for enzymolysis, and at the same time, during the enzymolysis process, every 13 minutes of static enzymolysis is supplemented by intermittent ultrasonic treatment for 60 seconds, and the cycle is operated 6 times ;

[0033] 3) Enzyme inactivation: the product obtained in step 2) is inactivated, and then freeze-dried at a temperature of -10°C to obtain the product;

[0034] The protein is vegetable protein;

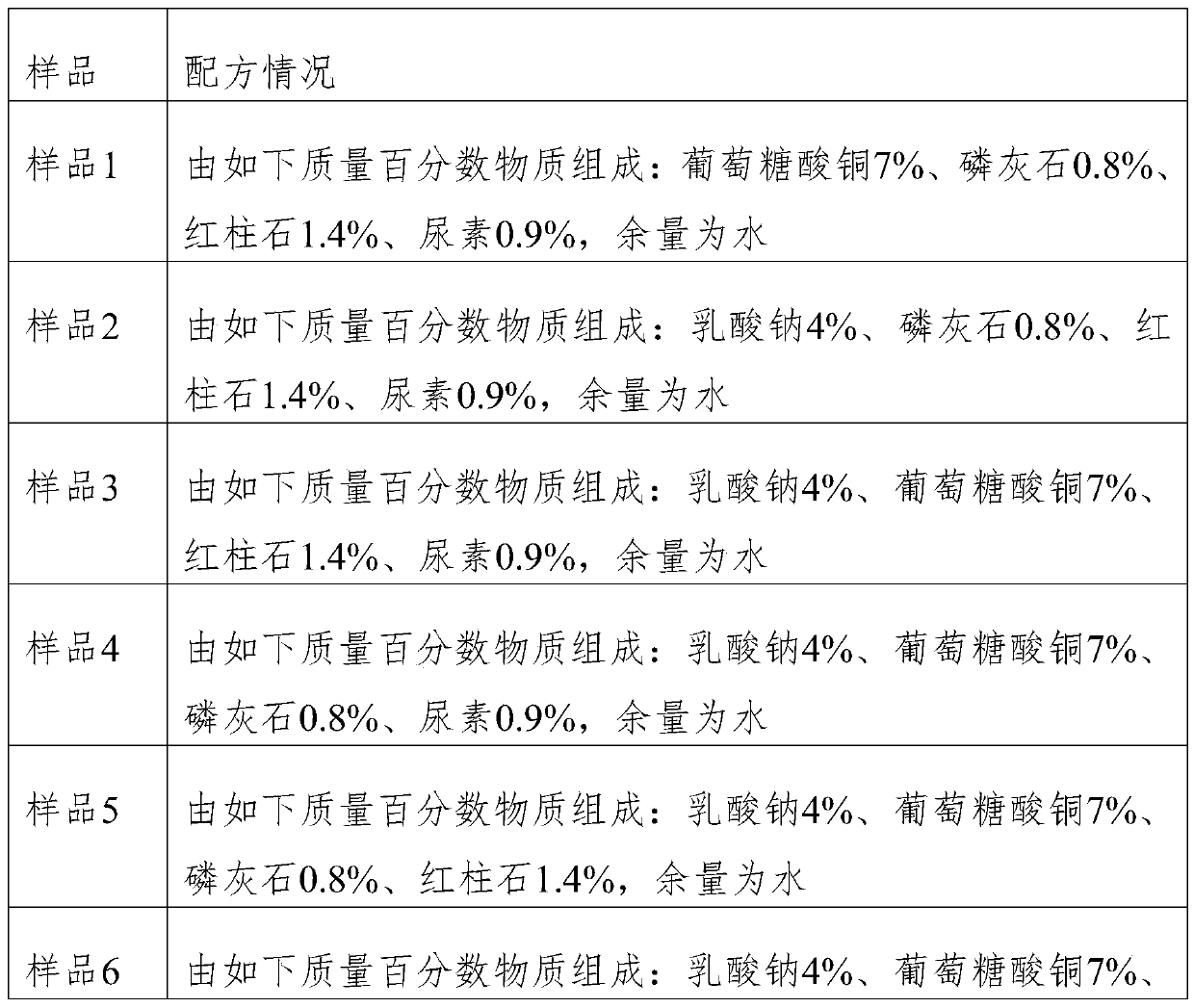

[0035] The swelling solution is composed of the following substances in mass percentage: 4% sodium lactate, 7...

Embodiment 2

[0042] A kind of production technology of whole enzyme polypeptide for fertilizer, comprises the following steps:

[0043] 1) Current-assisted swelling: the protein was placed in the swelling solution, treated with a constant voltage forward current for 12 minutes, and then treated with a constant voltage reverse current for 10 minutes;

[0044] 2) Ultrasound-assisted enzymolysis: add 0.1% of its mass activated compound enzyme preparation to the result of step 1) for enzymolysis, and at the same time, during the enzymolysis process, every 10 minutes of static enzymolysis is supplemented with intermittent ultrasonic treatment for 40 seconds, and the cycle is operated 3 times ;

[0045] 3) Enzyme inactivation: the product obtained in step 2) is inactivated, and then freeze-dried at a temperature of -20°C to obtain the product;

[0046] The protein is animal protein;

[0047] The swelling solution is composed of the following substances in mass percentage: 1% sodium lactate, 2% c...

Embodiment 3

[0054] A kind of production technology of whole enzyme polypeptide for fertilizer, comprises the following steps:

[0055] 1) Current-assisted swelling: the protein was placed in the swelling solution, treated with a constant voltage forward current for 15 minutes, and then treated with a constant voltage reverse current for 12 minutes;

[0056] 2) Ultrasound-assisted enzymolysis: add 0.3% of its mass activated compound enzyme preparation to the result of step 1) for enzymolysis, and at the same time, during the enzymolysis process, every 12 minutes of static enzymolysis is supplemented with intermittent ultrasonic treatment for 50 seconds, and the cycle is operated 4 times ;

[0057] 3) Enzyme inactivation: the product obtained in step 2) is inactivated, and then freeze-dried at a temperature of -15°C to obtain the product;

[0058] The protein is a microbial protein;

[0059] The swelling solution is composed of the following substances in mass percentage: 2% sodium lactat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com