Preparation method of high-temperature electric furnace heat-insulation porous ceramic lining

A technology of thermal insulation and porous ceramics, applied in the field of ceramic materials, can solve the problems of low porosity, hindrance to application, poor stability, etc., and achieve the effects of high porosity, precise and adjustable pore structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

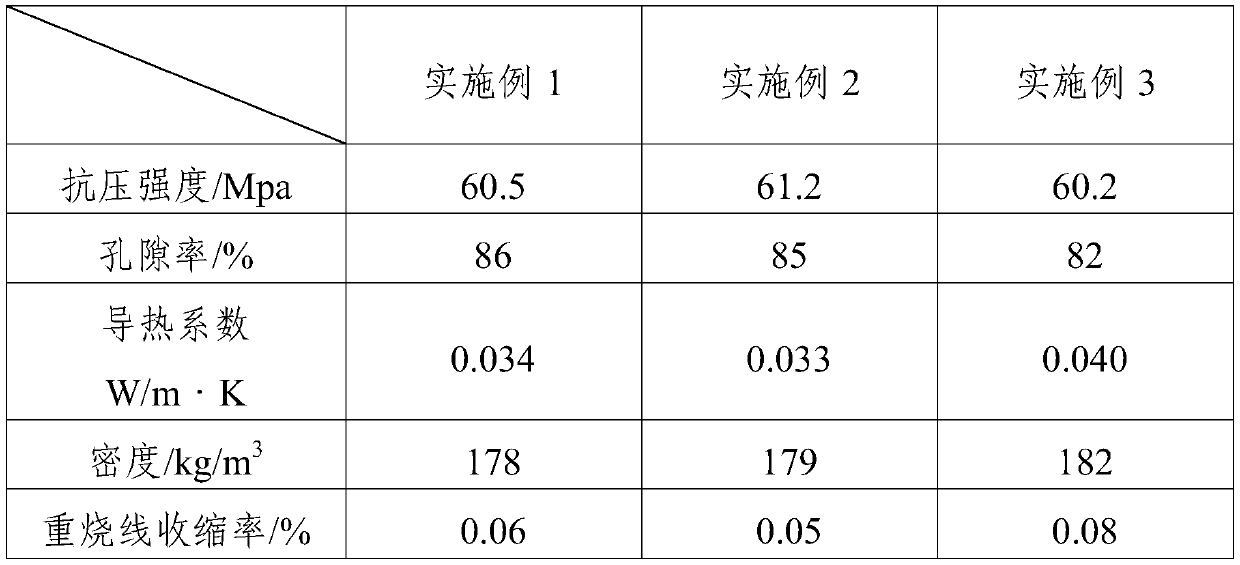

Embodiment 1

[0028] A method for preparing a heat-insulating and heat-preserving porous ceramic inner lining of a high-temperature electric furnace, specifically as follows:

[0029] Add dilute hydrochloric acid dropwise to the ethanol aqueous solution with a mass concentration of 28% to adjust the pH to 2-3, add tetraethyl orthosilicate dropwise under mechanical stirring at 400r / min, continue stirring for 35min after the dropping, and adjust the speed to 150r / min Add ammonia water dropwise in 1 minute until the pH of the system reaches 9-10. After reacting for 6 hours, the silica gel is obtained, which is allowed to stand at room temperature for 28 hours. Alkanes were replaced 3 times, each time for 13 hours, taken out and dried at 80°C for 12 hours, ground into powder and mixed with carbon black and trace nano-silicon carbide evenly, the weight ratio of dried silica gel to carbon black was 1:1.3, nitrogen Under protection, react at 1400°C for 3 hours to obtain a porous nano-silicon carbi...

Embodiment 2

[0031] A method for preparing a heat-insulating and heat-preserving porous ceramic inner lining of a high-temperature electric furnace, specifically as follows:

[0032] Add dilute hydrochloric acid dropwise to the ethanol aqueous solution with a mass concentration of 24% to adjust the pH to 2-3, add tetraethyl orthosilicate dropwise under mechanical stirring at 300r / min, continue stirring for 32min after dropping, adjust the speed to 180r / min Add ammonia water dropwise in 1 minute until the pH of the system reaches 9-10. After reacting for 5 hours, the silica gel is obtained, which is allowed to stand at room temperature for 30 hours. Alkanes were replaced 3 times, 12 hours each time, taken out and dried at 85°C for 15 hours, ground into powder and mixed evenly with carbon black and a small amount of nano-silicon carbide. The weight ratio of the dried silica gel to carbon black was 1:1.4, nitrogen Under protection, react at 1400°C for 4 hours to obtain a porous nano-silicon car...

Embodiment 3

[0034] A method for preparing a heat-insulating and heat-preserving porous ceramic inner lining of a high-temperature electric furnace, specifically as follows:

[0035] Add dilute hydrochloric acid dropwise to the ethanol aqueous solution with a mass concentration of 30% to adjust the pH to 2-3, add tetraethyl orthosilicate dropwise under 450r / min mechanical stirring, continue stirring for 40min after dropping, adjust the speed to 120r / min Add ammonia water dropwise in 1 minute until the pH of the system reaches 9-10. After 10 hours of reaction, the silica gel is obtained. Let it stand at room temperature for 28 hours. After immersing the silica gel in absolute ethanol at 40°C and aging it for 5 days, use n-hexane Alkanes were replaced 3 times, each time for 13 hours, taken out and dried at 95°C for 12 hours, ground into powder and mixed with carbon black and trace nano-silicon carbide evenly, the weight ratio of dried silica gel to carbon black was 1:1.5, nitrogen Under prot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap