Nutrient solution for soilless culture and preparation method thereof

A technology of soilless cultivation and nutrient solution, applied in the direction of application, liquid fertilizer, fertilizer mixture, etc., can solve the problem of strong bitter taste of vegetables, achieve the effects of good ion compatibility, promote synthesis, and improve taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] This embodiment provides a nutrient solution for soilless culture, and the steps are as follows:

[0068] (1) Weigh calcium nitrate 527mg, diammonium phosphate 600mg, potassium dihydrogen phosphate 437mg potassium sulfate 670mg, magnesium sulfate 500mg, EDTA iron sodium salt 6.44mg, manganese sulfate 1.72mg, zinc sulfate 1.46mg, boric acid 2.38mg, sulfuric acid Copper 0.2mg, sodium molybdate 0.13mg, soluble humic acid 6g, dissolved in softened tap water to form a mixed solution;

[0069] (2) Add a small amount of dilute sodium hydroxide solution to adjust the pH of the mixed solution to be neutral, that is, around 6.5-7.5;

[0070] (3) The pH-adjusted mixed solution is sterilized and disinfected by ultraviolet light combined with electricity to obtain nutrient solution A.

Embodiment 2

[0072] This embodiment provides a nutrient solution for soilless culture, and the steps are as follows:

[0073] (1) Weigh ammonium nitrate 400mg, urea 515mg, potassium dihydrogen phosphate 856mg, potassium sulfate 670mg, magnesium sulfate 460mg, EDTA iron sodium salt 5.73mg, manganese sulfate 1.57mg, zinc sulfate 1.46mg, boric acid 2.3mg, copper sulfate 0.17 mg, sodium molybdate 0.11mg, soluble humic acid 4.5g, dissolved in softened tap water to form a mixed solution;

[0074] (2) Add a small amount of dilute sodium hydroxide solution to adjust the pH of the mixed solution to be neutral, that is, around 6.5-7.5;

[0075] (3) The pH-adjusted mixed solution is sterilized and disinfected by ultraviolet light combined with electricity to obtain nutrient solution A.

Embodiment 3

[0077] This embodiment provides a nutrient solution for soilless culture, and the steps are as follows:

[0078] (1) Weigh potassium nitrate 477mg, ammonium nitrate 336mg, diammonium phosphate 255mg, potassium dihydrogen phosphate 637mg, potassium sulfate 218mg, magnesium sulfate 500mg, EDTA iron sodium salt 7.95mg, manganese sulfate 1.36mg, zinc sulfate 1.32mg, boric acid 2.4mg, copper sulfate 0.15mg, sodium molybdate 0.10mg, soluble humic acid 3.1g, dissolved in distilled water to form a mixed solution;

[0079] (2) Add a small amount of dilute sodium hydroxide solution to adjust the pH of the mixed solution to be neutral, that is, around 6.5-7.5;

[0080] (3) The pH-adjusted mixed solution is sterilized and disinfected by ultraviolet light combined with electricity to obtain nutrient solution A.

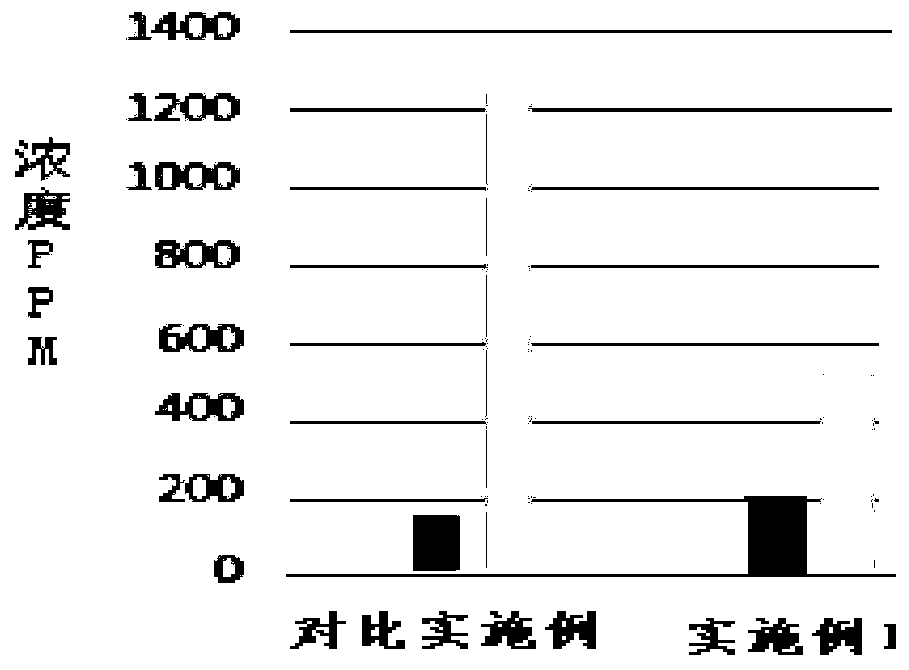

[0081] Comparative Example of Example 1

[0082] This embodiment provides a nutrient solution for soilless culture, and the steps are as follows:

[0083] (1) Weigh calcium nitrate 527mg, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com