Two-step surface conditioning agent used before aluminum anodic oxidation dyeing and preparation and application thereof

A technology of oxidative dyeing and surface adjustment, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of inability to carry out dyeing process normally, low yield rate of output, acid residue cleaning, etc., and achieve accelerated The effect of acid-base diffusion and reaction probability, improvement of processing quality level, and prevention of uneven dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned two-step table adjustment before aluminum anodizing and dyeing includes the following steps:

[0039] Preparation of alkaline meter adjustment: take formula amount of sodium bicarbonate, potassium bicarbonate or ammonia water and add it to deionized water to prepare 5-50g / l sodium bicarbonate solution, potassium bicarbonate solution or ammonia solution;

[0040] Preparation of acid metering agent: take formula amount of deionized water, add organic acid, stir well, then add corrosion inhibitor, stir well, then add inorganic salt, stir well; when using, dilute with deionized water to 40-200ml / l working solution, and use 10wt% nitric acid and 100g / L sodium hydroxide to adjust the pH to 1.2-2.5.

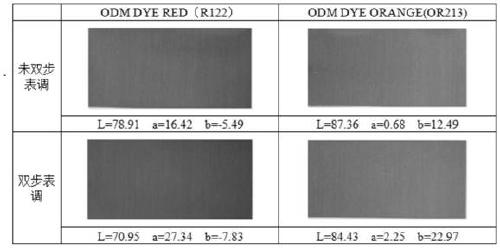

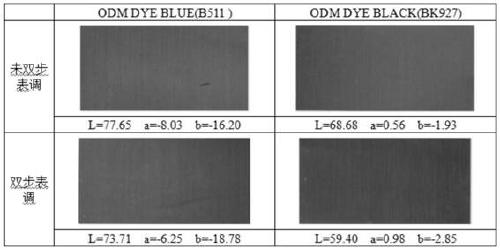

[0041] The application of the above-mentioned two-step table adjustment in the surface adjustment before the aluminum anodizing dyeing, firstly adjust the table adjustment with the alkaline table adjustment, and then adjust the table adjust...

Embodiment 1

[0046] The alkaline metering formula used in the alkaline metering step in this embodiment is: sodium bicarbonate solution 10g / l. The operating temperature is normal temperature, with auxiliary ultrasonic equipment processing, the ultrasonic frequency is 24kHz, and the operating time is 30s.

[0047] The acid metering formula used in the acid metering step is: 20 parts by mass of deionized water, 60 parts by mass of glycolic acid, 6 parts by mass of malic acid, 9 parts by mass of sodium nitrate, and 5 parts by mass of polyacrylic acid. Put deionized water into the liquid mixing tank, and then add the materials in the order of organic acid, corrosion inhibitor, and inorganic salt. Each substance must be fully stirred. After all the materials are added, fully stir and mix well. Dilute with deionized water to a 100ml / l working solution, and adjust the pH to 1.2 with 10wt% nitric acid and 100g / L sodium hydroxide. The operating temperature is 30°C, with auxiliary ultrasonic equipment...

Embodiment 2

[0052] The alkaline metering formula used in the alkaline metering step in this embodiment is: potassium bicarbonate solution 5g / l. The operating temperature is normal temperature, with auxiliary ultrasonic equipment processing, the ultrasonic frequency is 30kHz, and the operating time is 1min.

[0053] The acid metering formula used in the acid metering step is: 20 parts by weight of deionized water, 43 parts by weight of lactic acid, 11 parts by weight of maleic acid, 9 parts by weight of glycine, 9 parts by weight of sodium acetate, 6 parts by weight of polyvinyl alcohol, and 2 parts by mass of acrylic acid. Put deionized water into the liquid mixing tank, and then add the materials in the order of organic acid, corrosion inhibitor, and inorganic salt. Each substance must be fully stirred. After all the materials are added, fully stir and mix well. Dilute with deionized water to a 60ml / l working solution, use 10wt% nitric acid and 100g / L sodium hydroxide to adjust the pH to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com