Gamma-type high-entropy rare earth disilicate with ultrahigh-temperature stability and preparation method thereof

A silicate and stable technology, which is applied in the field of ceramic materials for thermal barrier/environmental barrier integrated coatings of advanced aero-engines, and can solve the problems of weak corrosion resistance of high temperature molten oxides, limited proportion of other elements, and high price. , to achieve the effect of single-phase purity, low density and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the primary particle size of the raw material gadolinium oxide, dysprosium oxide, holmium oxide, ytterbium oxide, lutetium oxide and silicon oxide powder is 100 mesh, and the purity is ≥99.9 wt%. Put 7.25g of gadolinium oxide, 7.46g of dysprosium oxide, 7.56g of holmium oxide, 7.88g of ytterbium oxide, 7.96g of lutetium oxide and 12.02g of silicon oxide, using absolute ethanol as the medium, put the powder into a silicon nitride ball mill jar and mill for 24 Hours, the dried powder was subjected to pressureless sintering synthesis in a muffle furnace. The pressureless sintering synthesis process is as follows: heating up to 1550°C at a rate of 5°C / min, holding the temperature for 6 hours, cooling with the furnace after the reaction, and finally preparing the target γ-type high-entropy rare earth bisilicate ceramic powder material. The volume average particle size is about 0.5-3 μm.

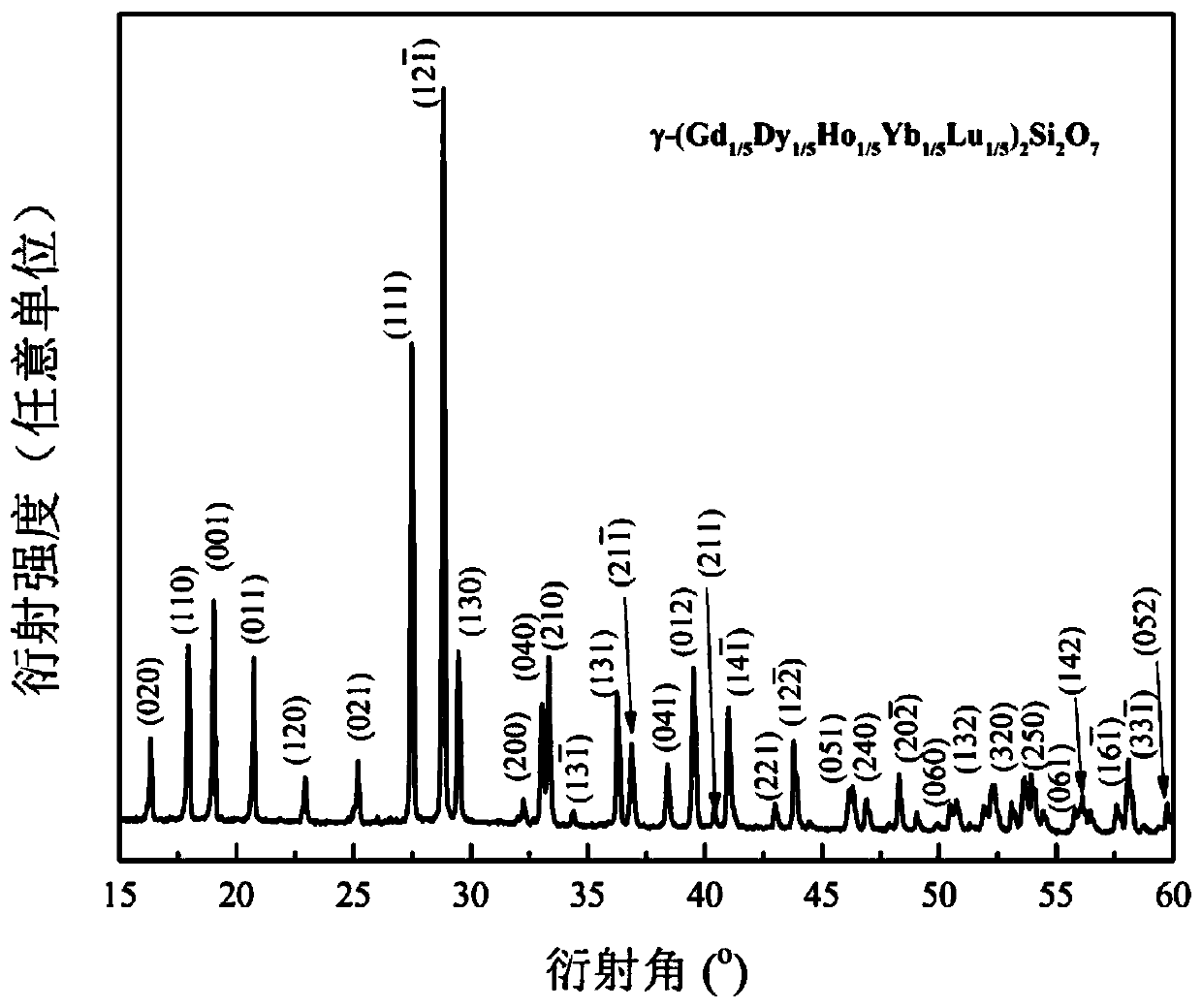

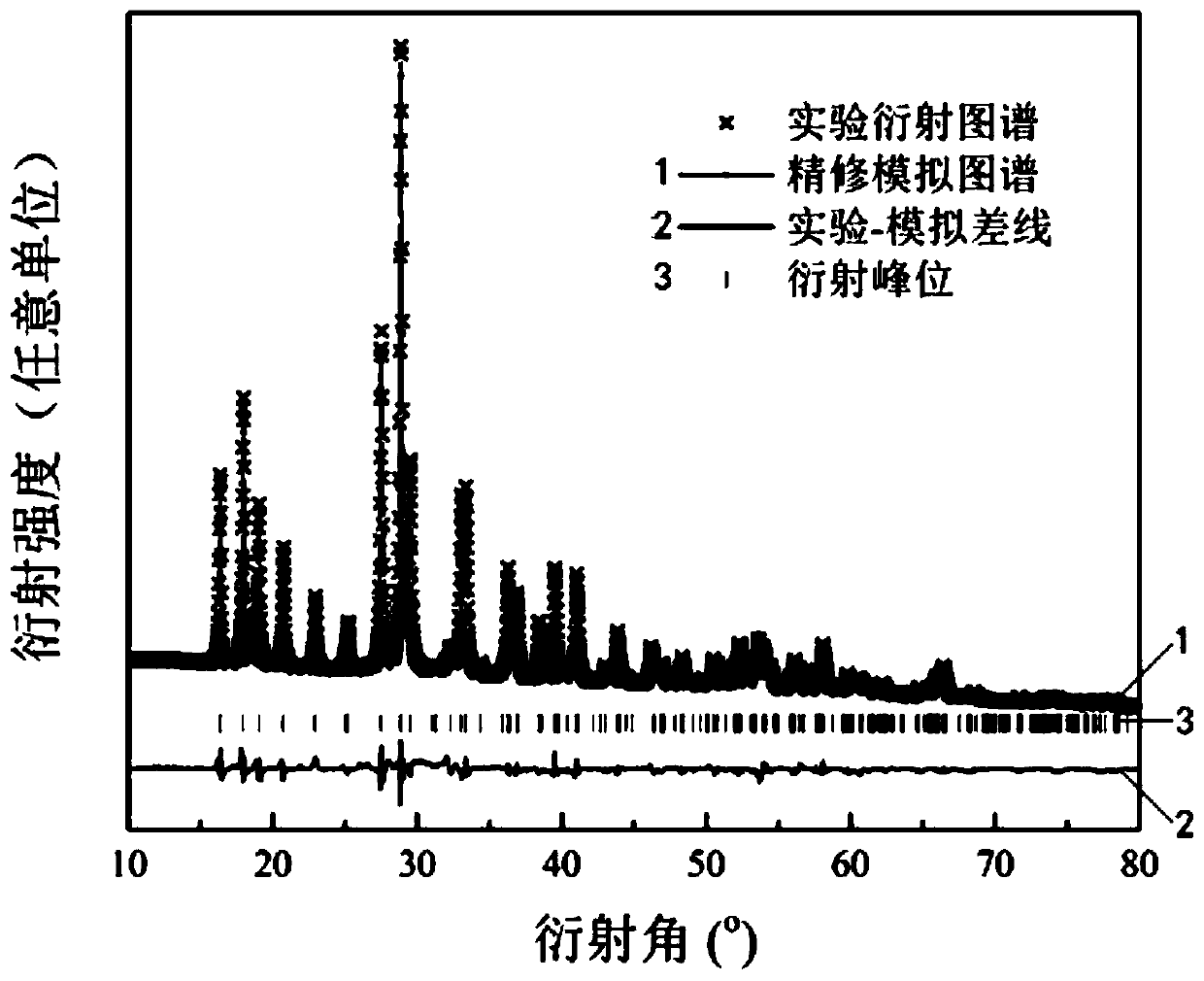

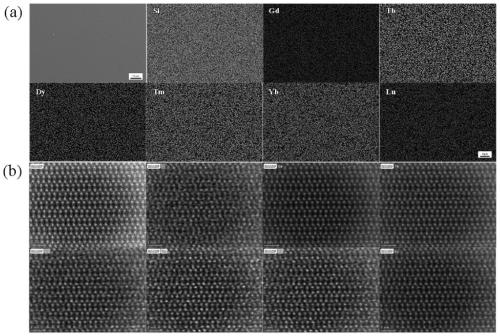

[0032] Such as figure 1 As shown, the reaction product obtained i...

Embodiment 2

[0034] In this embodiment, the primary particle size of the raw materials gadolinium oxide, dysprosium oxide, terbium oxide, thulium oxide, ytterbium oxide, lutetium oxide and silicon oxide powder is 200 mesh, and the purity is ≥99.9 wt%. Put 12.08 grams of gadolinium oxide, 12.43 grams of dysprosium oxide, 12.46 grams of terbium oxide, 12.86 grams of thulium oxide, 13.14 grams of ytterbium oxide, 13.26 grams of lutetium oxide and 24.05 grams of silicon oxide. The ball milled in a silicon ball mill jar for 8 hours, and the dried powder was sintered and synthesized in a muffle furnace without pressure. The pressureless sintering synthesis process is as follows: heating up to 1500°C at a rate of 15°C / min, holding the temperature for 20 hours, cooling with the furnace after the reaction, and finally preparing the target γ-type high-entropy rare earth bisilicate ceramic powder material. The volume average particle size is about 0.5-5 μm.

[0035] Put the powders synthesized by pr...

Embodiment 3

[0038] In this embodiment, the primary particle size of the raw materials gadolinium oxide, dysprosium oxide, terbium oxide, thulium oxide, ytterbium oxide, lutetium oxide and silicon oxide powder is 200 mesh, and the purity is ≥99.9 wt%. Put 12.08 grams of gadolinium oxide, 12.43 grams of dysprosium oxide, 12.46 grams of terbium oxide, 12.86 grams of thulium oxide, 13.14 grams of ytterbium oxide, 13.26 grams of lutetium oxide and 24.05 grams of silicon oxide. The ball milled in a silicon ball mill jar for 2 hours, and the dried powder was sintered and synthesized in a muffle furnace without pressure. The pressureless sintering synthesis process is as follows: heating up to 1650°C at a rate of 10°C / min, holding the temperature for 0.5 hours, cooling with the furnace after the reaction, and finally preparing the target γ-type high-entropy rare earth bisilicate ceramic powder material. The volume average particle size is about 2-5 μm.

[0039] Put the powder after pressureless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com