Photoresist and method of forming photolithographic pattern

A technology of photoresist and positive photoresist, which is applied in the field of photoresist and can solve the problems of low resolution and sensitivity of photoresist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] According to a typical embodiment of the present invention, a photoresist is provided. Photoresists contain the following components:

[0039] (A) 5-85 parts by mass of resin;

[0040] (B) 0.01 to 20 parts by mass of a photoacid generator;

[0041] (C) 0.005 to 10 parts by mass of additives;

[0042] (D) the solvent of 20~90 mass parts;

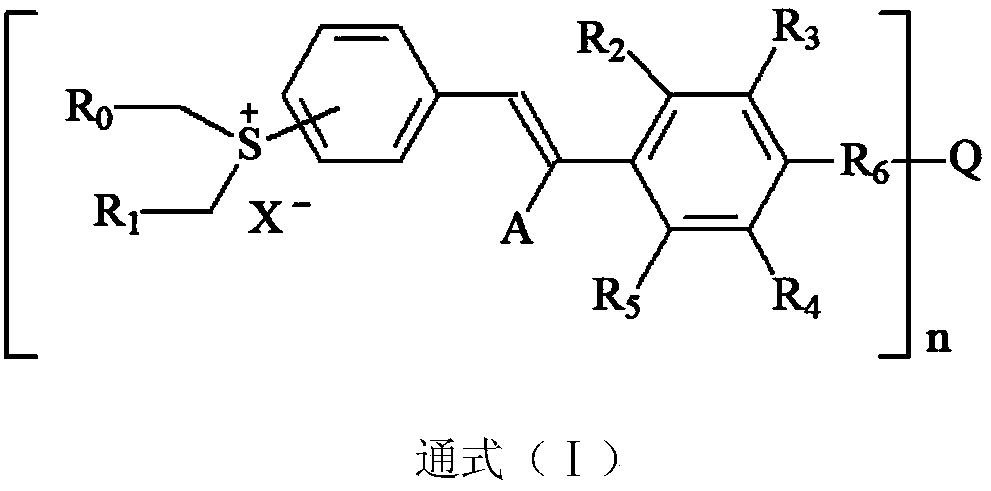

[0043] Wherein, the photoacid generator has a structure as shown in general formula (I):

[0044]

[0045] In the compound structure of the above general formula (I):

[0046] (1)R 0 and R 1 represent hydrogen independently of each other, or i.e. R 0 can represent the R 7 ,R 8 ,R 9 ,R 10 ,R 11 Substituted aryl, R 1 can represent the R 12 ,R 13 ,R 14 ,R 15 ,R 16 Substituted aryl (as shown in the general formula (I), and then form a methyl or different substituted benzyl sulfonium salt structure), wherein R 7 ,R 8 ,R 9 ,R 10 ,R 11 ,R 12 ,R 13 ,R 14 ,R 15 ,R 16 Independently represent hydrogen, halogen a...

Embodiment 1

[0127] Preparation of phenolic resin:

[0128] According to the ratio shown in Table 1, m-cresol (99wt%), p-cresol (99wt%), 3,5-xylenol (99wt%), and dihydrate oxalic acid were added to the , heating mantle, nitrogen-protected reactor, first add 20wt% of the formalin solution (36.9wt%) of the amount shown in Table 1, and be heated to 60°C under the condition of nitrogen, and now the exothermic reaction begins . When the reaction temperature was raised to about 100°C, the remaining formalin solution was gradually added within 30 minutes, and then continued to react at reflux temperature for 4 hours to generate polycondensate. Under the protection of atmospheric nitrogen, the volatile components such as formaldehyde and water were distilled off. When the temperature of the polycondensate was raised to 210°C, the unreacted monomer was removed by vacuum distillation under reduced pressure until the temperature reached 228°C and the vacuum degree reached 7 mmHg. Pour the polycond...

Embodiment 2

[0132]Acrylic resin preparation:

[0133] According to the ratio shown in Table 2, 0.5 mol of A-1, 0.15 mol of B-1, 0.2 mol of C-1 and 0.005 mol of 2,2'-azobis(isobutyric acid) dimethyl Dissolve in 80 g of methyl ethyl ketone, and react under nitrogen atmosphere at 80° C. for 2 hours with stirring. After the reaction, cool to room temperature, then add the polymerization solution dropwise into 400g of n-hexane, filter after precipitation, wash with a mixed solvent of methyl ethyl ketone and n-hexane three times, and dry in vacuum at 50°C for 20 hours to obtain a white The powder solid polymer compound is acrylic resin-1. Acrylic resin 2-4 was obtained by the same preparation method.

[0134] Table 2 Acrylic resin formula

[0135]

[0136]

[0137] In the above table 2, the structural formula of each unit is as follows in table 3:

[0138] Table 3 Structure of each unit in Table 2

[0139]

[0140]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com