Metal lithium composite negative electrode material and preparation method and application thereof

A negative electrode material, metal lithium technology, applied in the field of metal lithium composite negative electrode materials and its preparation, can solve the problems of short life, serious side reactions, low Coulombic efficiency, etc., achieve high mechanical strength, high production controllability, and promote migration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A metal lithium composite negative electrode material, which is prepared through the following steps:

[0030] S1: Heat metal lithium to 200-1200°C to make the metal lithium into a molten state, add elemental silicon (Si) to the molten metal lithium, keep it warm for 5-60 minutes, mix evenly, form a molten lithium-silicon alloy, and let stand , cooled to room temperature to obtain a lithium-silicon alloy material, wherein the molar ratio of silicon (Si) to lithium metal is 1:30;

[0031] S2: Take 1g of polymethyl methacrylate (PMMA) in a 20mL glass bottle, add 10mL of dimethylformamide (DMF), stir and dissolve to obtain a polymer solution;

[0032] S3: After the polymethyl methacrylate is completely dissolved, add 0.178g of lithium bistrifluoromethylsulfonimide (LiTFSI) to it, and mechanically stir to obtain a uniformly dispersed polymer electrolyte solution; the polymethyl methacrylate in the polymer electrolyte solution The mixing molar ratio of methyl acrylate and l...

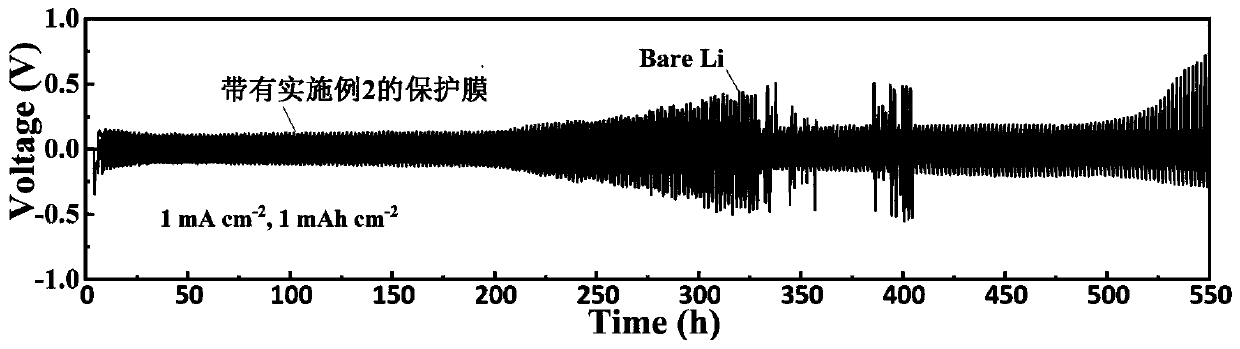

Embodiment 2

[0035] A metal lithium composite negative electrode material, which is prepared through the following steps:

[0036] S1: Add 10g of ethylene vinyl alcohol copolymer (ethylene=38%) and 100mL of dimethylformamide (DMF) to the round bottom flask, stir at a constant speed and maintain the temperature at 90°C to dissolve; when the ethylene vinyl alcohol copolymer is completely dissolved, stop Heat it, let it cool to 40° C., then add 0.1 g of sodium hydroxide thereto, continue stirring, then add 24.7 mL of acrylonitrile dropwise, and carry out stirring at about 40° C. for 5 hours to carry out contact of ethylene vinyl alcohol and acrylonitrile Branch reaction;

[0037] S2: Take 10 mL of the ethylene vinyl alcohol graft mixture solution obtained in S1 in a 20 mL glass bottle, add 0.252 g of lithium bistrifluoromethanesulfonimide (LiTFSI) to it and stir overnight to obtain a polymer electrolyte solution; The mixing molar ratio of the graft copolymer in the polymer electrolyte soluti...

Embodiment 3

[0040] A metal lithium composite negative electrode material, which is prepared through the following steps:

[0041] S1: Heat metallic lithium to 200-800°C to make the metallic lithium a molten state, add metallic copper (Cu) to the molten metallic lithium, keep it warm for 5-60 minutes, mix evenly, form a molten alloy, let stand, and cool To room temperature, obtain lithium-copper alloy material, wherein, the mol ratio of copper (Cu) and metal lithium is 1:60;

[0042] S2: Take 0.5g polyvinylidene fluoride: (PVDF) in a 20mL glass bottle, add 10mL dimethylformamide (DMF), stir and dissolve to obtain a polymer solution;

[0043] S3: After polyvinylidene fluoride is completely dissolved, add 5 mg of aluminum oxide (Al 2 o 3 ), ultrasonic until uniformly dispersed, then add 0.062g lithium perchlorate (LiClO 4 ), mechanical stirring to obtain a uniformly dispersed polymer electrolyte solution;

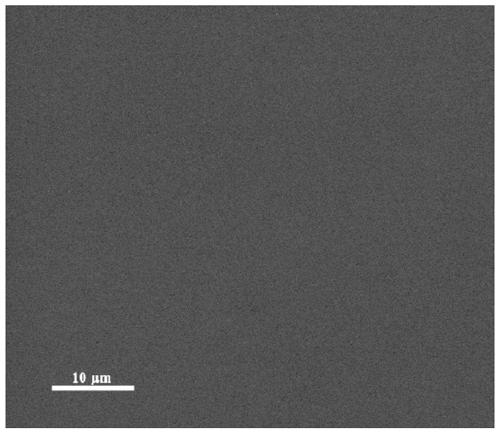

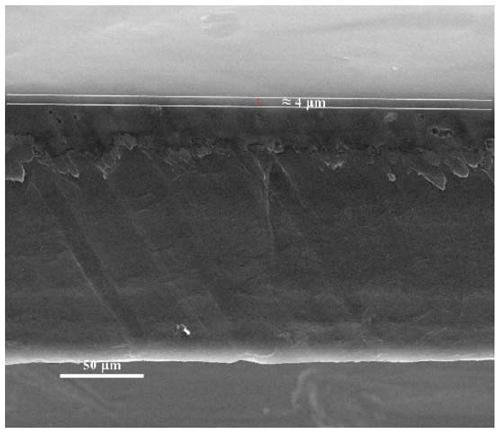

[0044] S4: Take a certain amount of polymer electrolyte solution and coat it on m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com