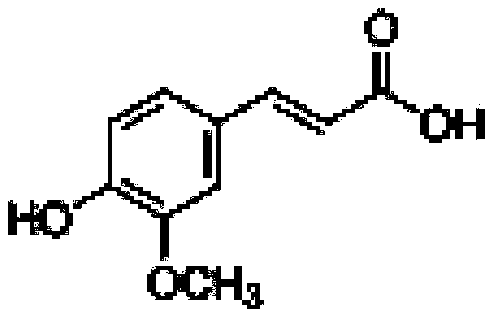

Method for preparing natural ferulic acid by taking nigre containing oryzanol as raw material

A technology of oryzanol and ferulic acid, which is applied in the field of plant extraction and separation, can solve the problems of low efficiency, complicated treatment, and pollution of natural ferulic acid, and achieve the effects of easy temperature control, complete decolorization, and less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 1. Alkali-alcohol hot-melt filtration. 3m ahead 3 Add 1200L of edible ethanol with a concentration of 89% in the extraction tank, put 400kg of oryzanol-containing soapstock raw materials into the extraction tank under constant stirring, continue to add 1200L of edible ethanol with a concentration of 89%, keep stirring continuously and heat, and heat up to 52°C. The pH of the system was adjusted to 9.0 with a 6% dilute sodium hydroxide aqueous solution to dissolve the raw material, and the material was passed through a disc centrifuge while it was hot, and the filtrate was collected to obtain 2650 L of dissolved filtrate.

[0069] 2. Acid precipitation and separation. Adjust the pH of the dissolved filtrate to 6.5 with dilute sulfuric acid with a concentration of 5wt%, stir well, and let stand for 6 hours to make the oryzanol precipitate completely, and collect the centrifugal precipitate by a three-legged sedimentation centrifuge to obtain 261 kg of the centrifugal pre...

Embodiment 2

[0080] 1. Alkali-alcohol hot-melt filtration. 3m ahead 3 Add 1000L of edible ethanol with a concentration of 92% in the extraction tank, put 300kg of oryzanol-containing soapstock raw material into the extraction tank under constant stirring, continue to add 1000L of edible ethanol with a concentration of 92%, keep stirring and heating continuously, and heat up to 55°C. The pH of the system was adjusted to 10.0 with a 5% dilute sodium hydroxide aqueous solution to dissolve the raw material, and the material was passed through a three-legged sedimentation centrifuge while it was hot, and the filtrate was collected to obtain 2160 L of dissolved filtrate.

[0081] 2. Acid precipitation and separation. Adjust the pH of the dissolved filtrate to 7.0 with dilute hydrochloric acid with a concentration of 8 wt%, stir well, and let stand for 5 hours to make the oryzanol precipitate completely, and collect the centrifugal precipitate by a three-legged sedimentation centrifuge to obtain...

Embodiment 3

[0092] Others are the same as in Example 1, the difference is that the pH of the system is adjusted to 9.0 with dilute lye in step (1); the pH of the dissolved filtrate is adjusted to 7.0 with dilute acid in step (2); the alkali alcohol is adjusted with dilute sulfuric acid in step (6) The pH of the hydrolysis filtrate was 4.0. After testing, the finished product has a natural ferulic acid content of 98.73%, is pure white by visual inspection, and has a product yield of 82.31%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com