Preparation method and application of dumbbell-shaped fluorine-containing polyphosphazene modified halloysite nanotubes

A technology of halloysite nanotubes and fluorine-containing polyphosphazene, which is applied in the field of flame-retardant materials, can solve problems such as poor hydrophobicity, poor heat resistance, and performance defects, so as to reduce mass and energy transfer and improve mechanical properties , the effect of inhibiting combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

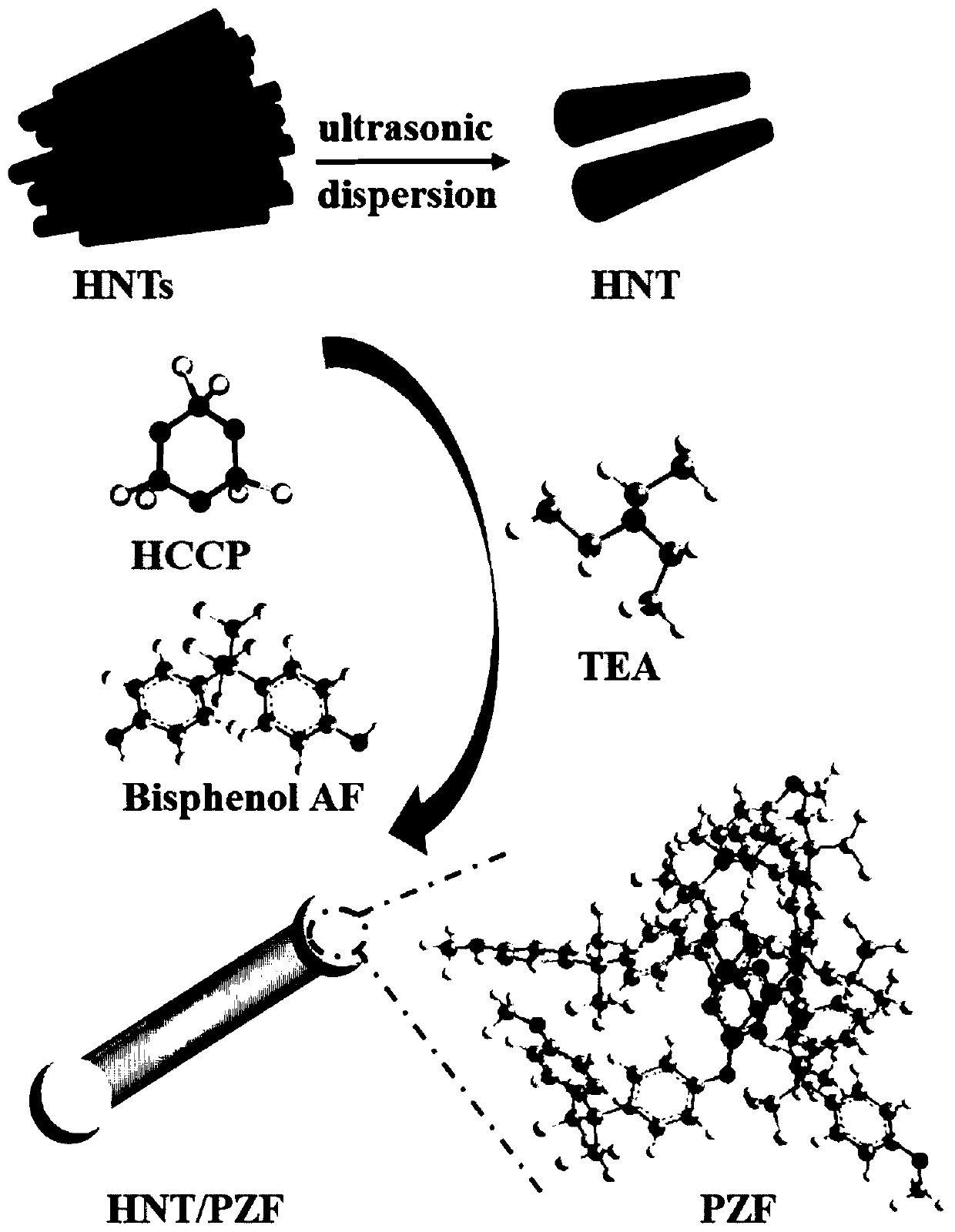

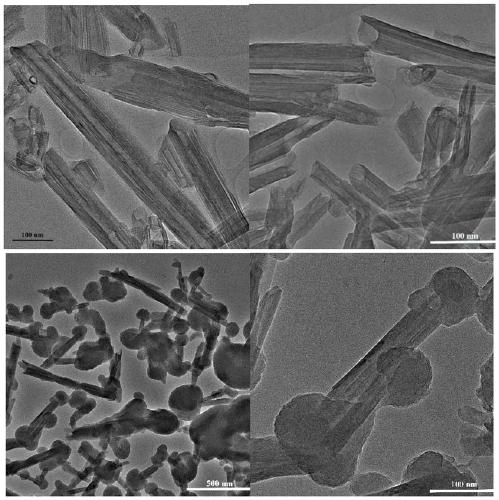

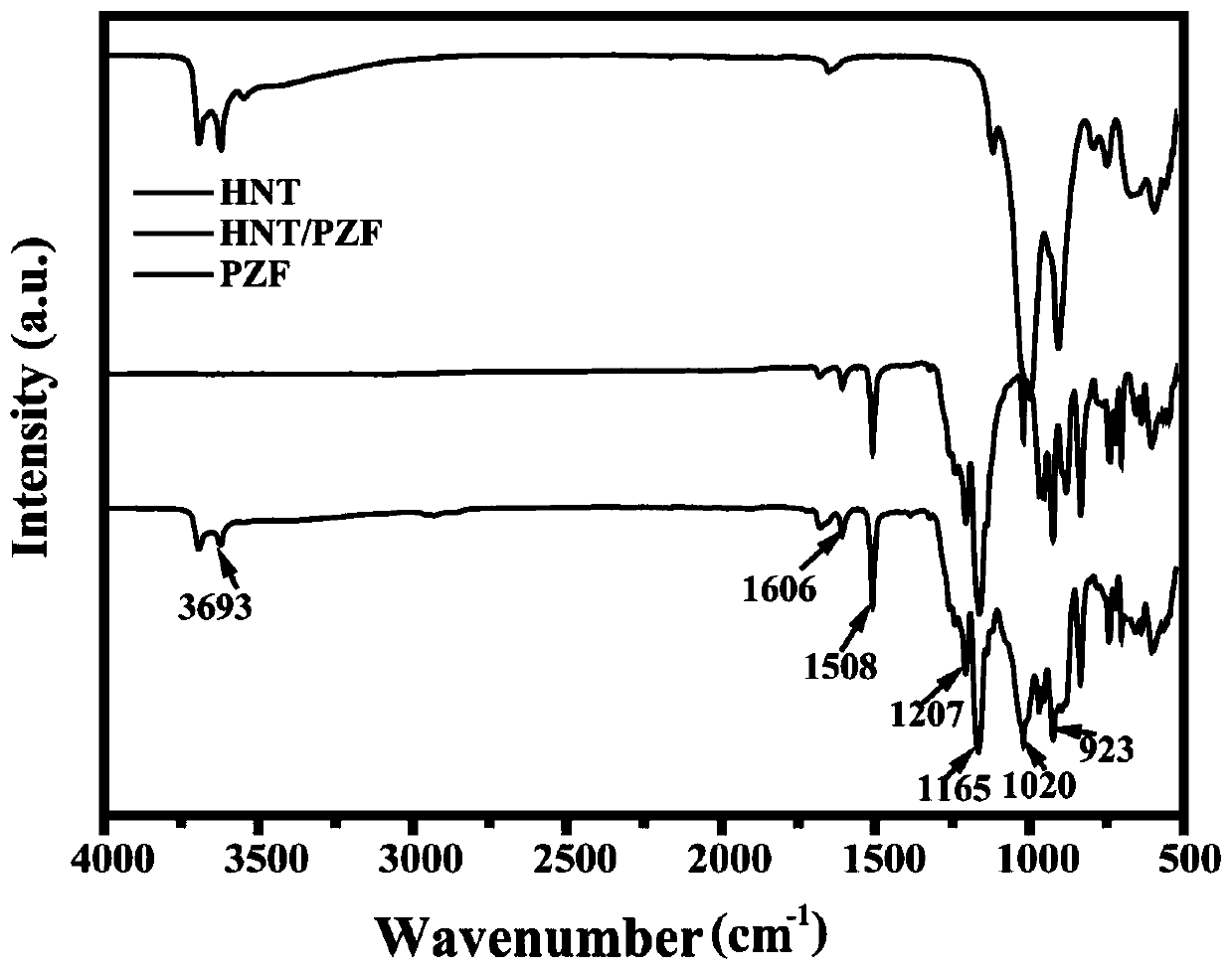

[0037] (1) Preparation of dumbbell-shaped fluorine-containing polyphosphazene-modified halloysite nanotubes: Polyphosphazene polymer is polycondensed at both ends of the halloysite nanotubes, such as figure 1 As shown, specifically: ①Add 0.1-0.5g halloysite nanotubes into the reaction vessel and ultrasonically disperse them in acetonitrile solvent to obtain a dispersion solution; ②Add double-terminal hydroxyl groups to the dispersion solution of halloysite nanotubes fluorine-containing substances, ultrasonically disperse for 30min-1h; ③Slowly drop the acetonitrile solution dissolved in hexachlorocyclotriphosphazene into the above solution, the dropping time is controlled at 30min-50min, and then ultrasonic again for 30min-1h. ④Add an appropriate amount of triethylamine to the above reaction system as an acid-binding agent, and stir at 60-80°C for condensation polymerization for 6-24h; Under the condition of 40-80° C., vacuum drying is carried out to a constant weight to obtain...

Embodiment 2

[0041] (1) Preparation of pure epoxy resin: Weigh 20g of E51 type bisphenol A epoxy resin, heat up to 80°C, add 5g of curing agent 4,4'-diaminodiphenylmethane, stir evenly and vacuumize to remove air bubbles Pour it into the preheated mold, and program the temperature according to the following temperature and time: 120°C / 4h, 140°C / 2h, 180°C / 2h.

[0042] (2) Utilize the dumbbell-shaped fluorine-containing polyphosphazene-modified halloysite nanotubes prepared in Example 1 to modify the epoxy resin: take 20g of E51 type bisphenol A epoxy resin, heat up to 80°C, Weigh 0.2g of dumbbell-shaped fluorine-containing polyphosphazene modified halloysite nanotubes, use acetone for ultrasonic dispersion for 30min, then slowly add to E51 type bisphenol A epoxy resin, remove the solvent under vacuum, and add 5g of curing agent 4,4'-diaminodiphenylmethane, stirred evenly, poured into the mold, and solidified with gradient temperature rise (120°C / 4h, 140°C / 2h and 180°C / 5h in sequence), and f...

Embodiment 3

[0050] (1) Preparation of pure polylactic acid: Dry 100g PLA in an air-blast drying oven at 80°C for 6h, banbury for 10min at a temperature of 175°C and a speed of 100r / min, and mix the samples at 185°C The flat vulcanizing machine is molded into a 3.2mm thick plate and cut into standard splines for later use.

[0051] (2) Utilize the dumbbell-shaped fluorine-containing polyphosphazene-modified halloysite nanotubes prepared in Example 1 to modify polylactic acid: 100g PLA, 5g dumbbell-type fluorine-containing polyphosphazene-modified halloysite nanotubes The preparation of the tube is dried in a blast drying oven at 80°C for 6 hours. After the two materials are mixed, they are banburyed for 10 minutes at a temperature of 175°C and a speed of 100r / min. Molded by a vulcanizing machine into a 3.2 mm thick plate and cut into standard splines for later use to obtain flame-retardant polylactic acid, wherein the content of the dumbbell-shaped fluorine-containing polyphosphazene-modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com