Method for preparing methane by using magnetosomes to promote reduction of CO2(subscript) with microbial electro-fermentation

A microbial electricity and magnetosome technology, applied in fermentation, waste fuel, etc., can solve the problems of limited performance improvement effect of fermentation system, difficult recovery and recycling, and limited application of anaerobic fermentation, so as to optimize electron transfer performance and reduce biogas. The effect of purification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

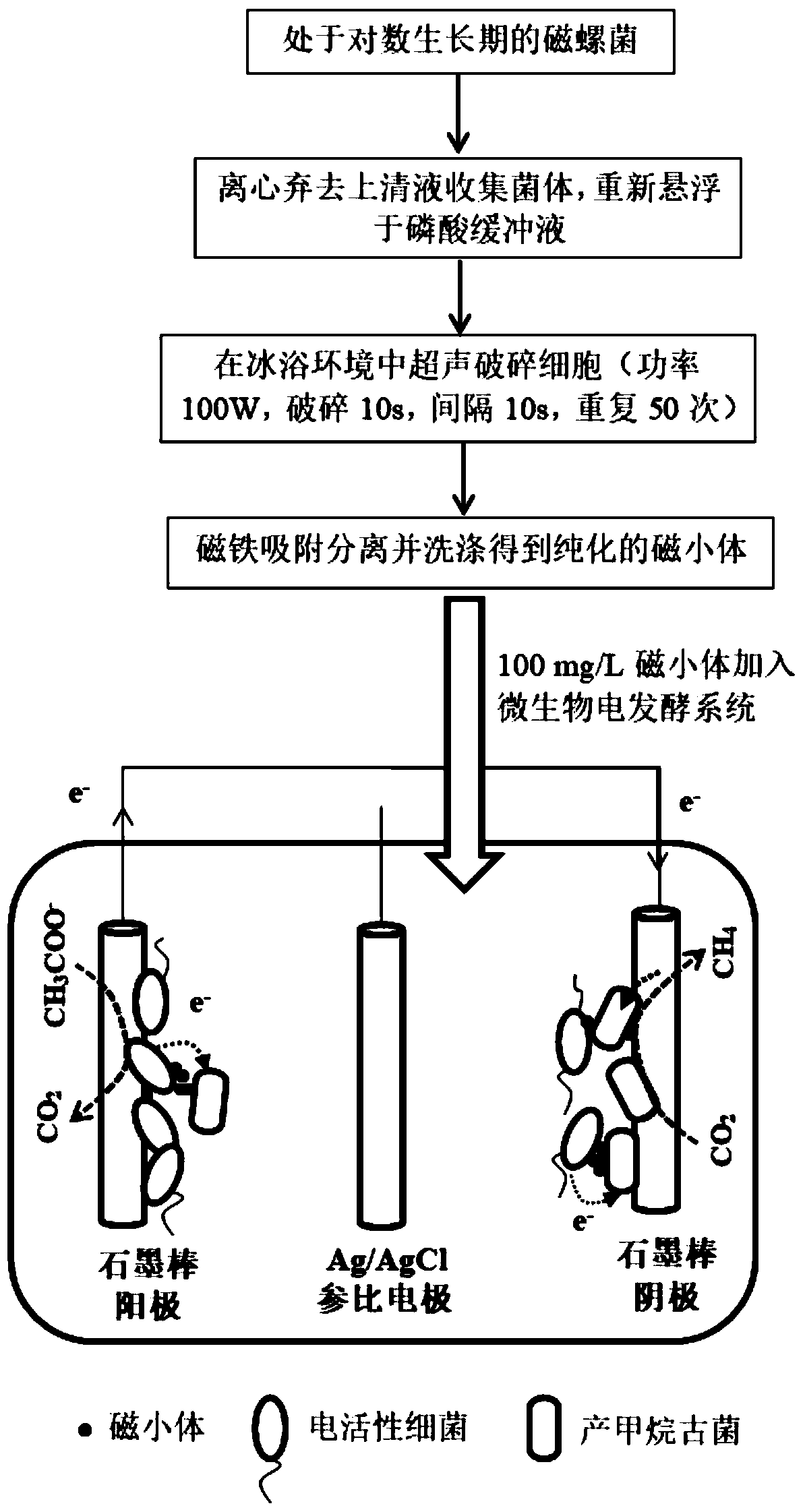

[0028]Cultivate Magnespira to the logarithmic growth phase, collect the cells by centrifugation and resuspend them in phosphate buffer, ultrasonically disrupt the cells in an ice bath environment (power 100W, disrupt 10s, interval 10s, repeat 50 times), separate by magnet adsorption Magnetosomes were washed five times with phosphate buffer to obtain purified magnetosome samples, and the magnetosomes were used as exogenous conductive additives to enhance the electron transfer performance in the microbial electrofermentation system. Small-molecule organic acid salts were used as the carbon source of the electrofermentation system, and anaerobic activated sludge rich in electroactive bacteria and methanogenic archaea (taken from a stably operating electrofermentative methanogenesis reactor) was selected as the inoculum. The microbial electrofermentation system adopts a three-electrode system. Two graphite rod electrodes (Φ0.5cm×7.5cm) are selected as the cathode and anode, and the...

Embodiment 2

[0030] Cultivate Magnespira to the logarithmic growth phase, collect the cells by centrifugation and resuspend them in phosphate buffer, ultrasonically disrupt the cells in an ice bath environment (power 100W, disrupt 10s, interval 10s, repeat 50 times), separate by magnet adsorption Magnetosomes were washed five times with phosphate buffer to obtain purified magnetosome samples, and the magnetosomes were used as exogenous conductive additives to enhance the electron transfer performance in the microbial electrofermentation system. Small-molecule organic acid salts were used as the carbon source of the electrofermentation system, and anaerobic activated sludge rich in electroactive bacteria and methanogenic archaea (taken from a stably operating electrofermentative methanogenesis reactor) was selected as the inoculum. The microbial electrofermentation system adopts a three-electrode system. Two graphite rod electrodes (Φ0.5cm×7.5cm) are selected as the cathode and anode, and th...

Embodiment 3

[0032] Cultivate Magnespira to the logarithmic growth phase, collect the cells by centrifugation and resuspend them in phosphate buffer, ultrasonically disrupt the cells in an ice bath environment (power 100W, disrupt 10s, interval 10s, repeat 50 times), separate by magnet adsorption Magnetosomes were washed five times with phosphate buffer to obtain purified magnetosome samples, and the magnetosomes were used as exogenous conductive additives to enhance the electron transfer performance in the microbial electrofermentation system. Small-molecule organic acid salts were used as the carbon source of the electrofermentation system, and anaerobic activated sludge rich in electroactive bacteria and methanogenic archaea (taken from a stably operating electrofermentative methanogenesis reactor) was selected as the inoculum. The microbial electrofermentation system adopts a three-electrode system. Two graphite rod electrodes (Φ0.5cm×7.5cm) are selected as the cathode and anode, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com