Infrared detector and manufacturing method thereof

A technology for infrared detectors and manufacturing methods, which is applied in the directions of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., and can solve the restrictions on the industrialization of medium-wave InAs/InAsSb superlattice detectors and the extremely difficult preparation of antimony containing Al Compounds, reducing device performance and reliability, etc., to avoid oxidation problems, reduce the difficulty of formation, and increase the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] As a kind of implementing method of infrared detector of the present invention, this method comprises:

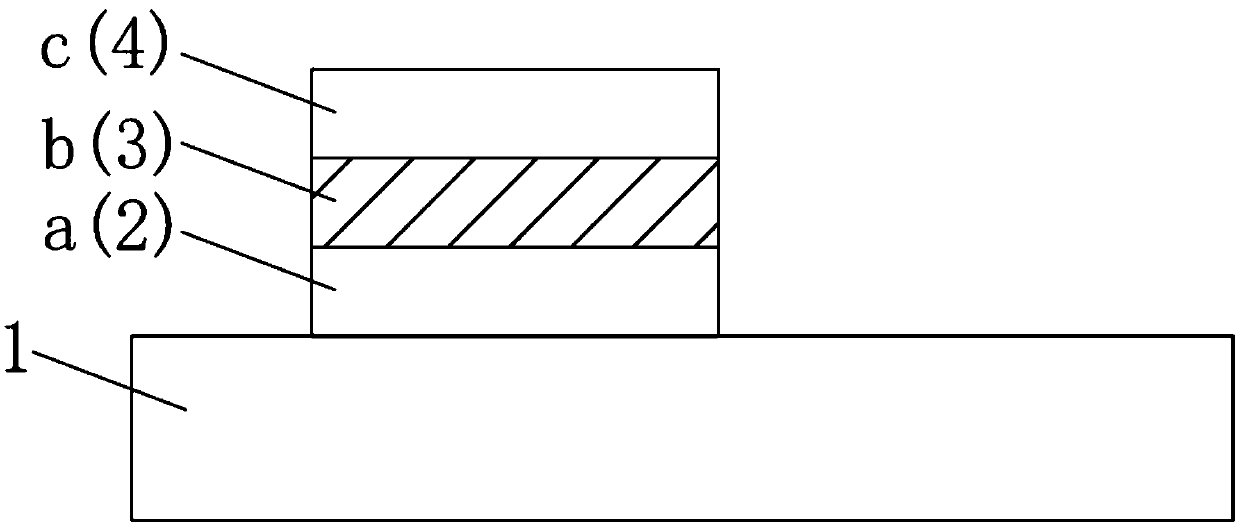

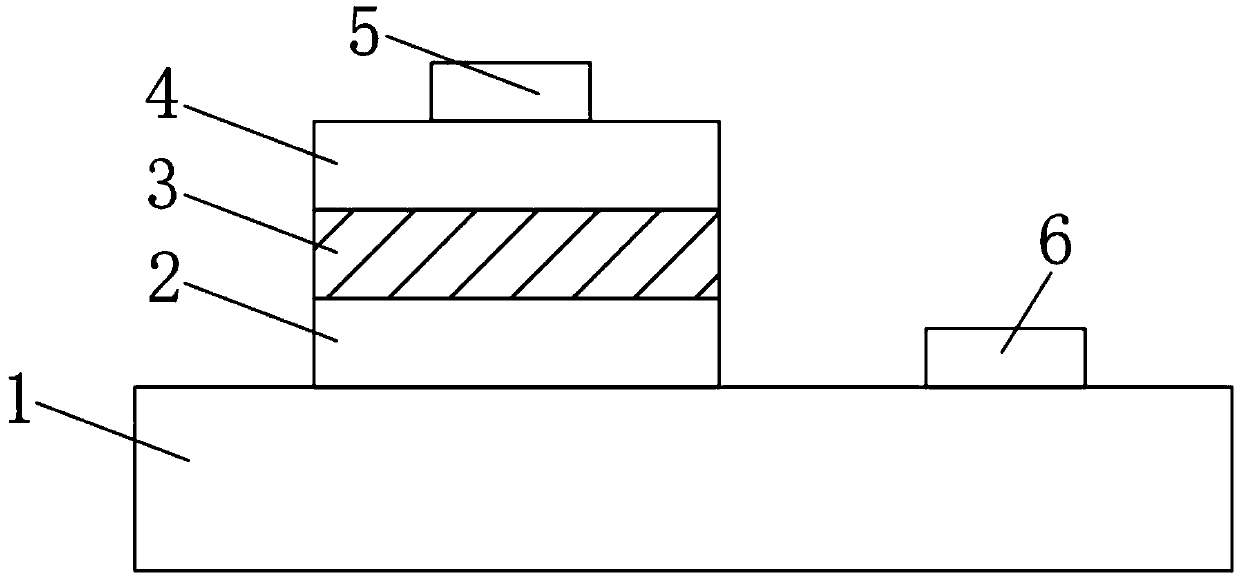

[0029] Step S1, on an N-type substrate 1 (preferably an N-type InAs substrate with a doping concentration of 1×10 19 cm -3 ) to form a detector mesa, the detector mesa includes an N-type InAsP / InAsSb superlattice absorption layer 2, an InPSb barrier layer 3 and an N-type InAsP / InAsSb stacked on the N-type substrate 1 in sequence Superlattice contact layer 4 .

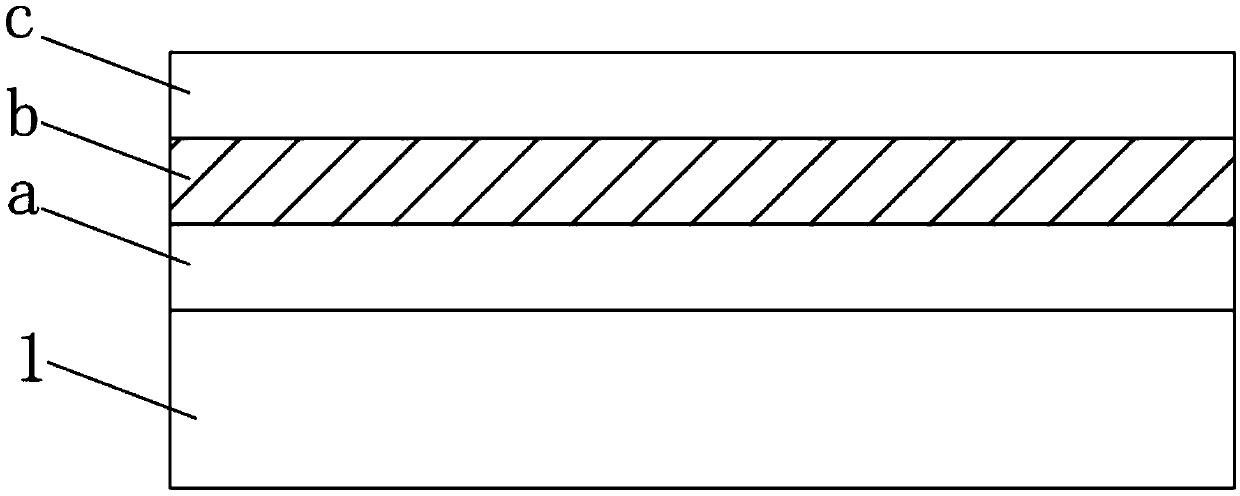

[0030] Specifically, such as figure 1 As shown, in this step, after the N-type substrate 1 is subjected to high-temperature treatment to remove surface impurities, the stacked first N-type InAsP / InAsSb superlattice layer a, InPSb layer b, second N-type InAsP / InAsSb superlattice layer c. Among them, the growth source is TMIn, TMSb, AsH 3 and PH 3 , N-type dopant source is SiH 4 , the growth temperature is 600°C, and the reaction chamber pressure is 200Torr. Wherein, the InPSb layer b is not doped, has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com