Macromolecule-loaded oxidizing agent containing iodine with high valence, and preparation method and application thereof

A high-valence iodine and high-molecular loading technology, applied in the field of oxidants, achieves the effects of mild reaction conditions, broad application prospects, and convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

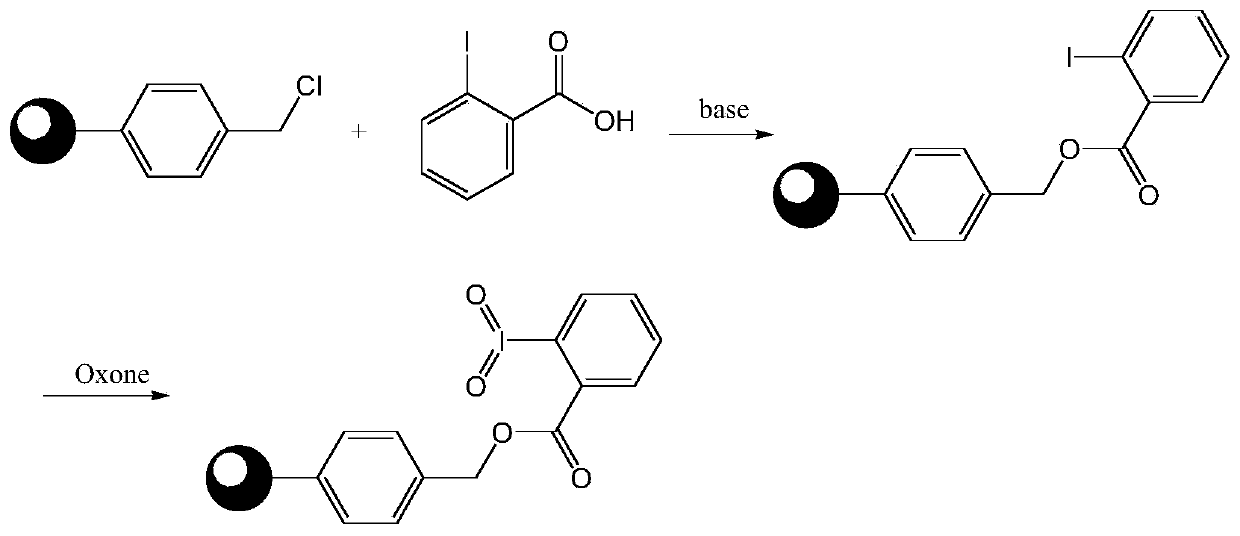

Embodiment 1

[0021] Add 600 ml of N,N-dimethylformamide and 150 g of chloromethyl polystyrene resin (1% DVB cross-linked, 100–200 mesh, 1.1 mmol / g) into a reaction flask equipped with a mechanical stirrer, Stir at room temperature for 2 hours; then add 61.4 gram of 2-iodobenzoic acid (molecular weight is 248), 13.8 gram of potassium hydroxide powder (molecular weight is 56) and 3.76 gram cesium fluoride (molecular weight is 152); Stir at room temperature for 30 minutes, Then stirred at 60-80 degrees for 5 hours; filtered after cooling to room temperature, the resin was successively washed with 200 ml of water, 200 ml of methanol, 200 ml of methylene chloride, 200 ml of methanol, 200 ml of methylene chloride, and 200 ml of dichloromethane. Washed with 1 ml of methanol; after vacuum drying overnight, 179.8 g of 2-iodobenzoic acid substituted resin was obtained.

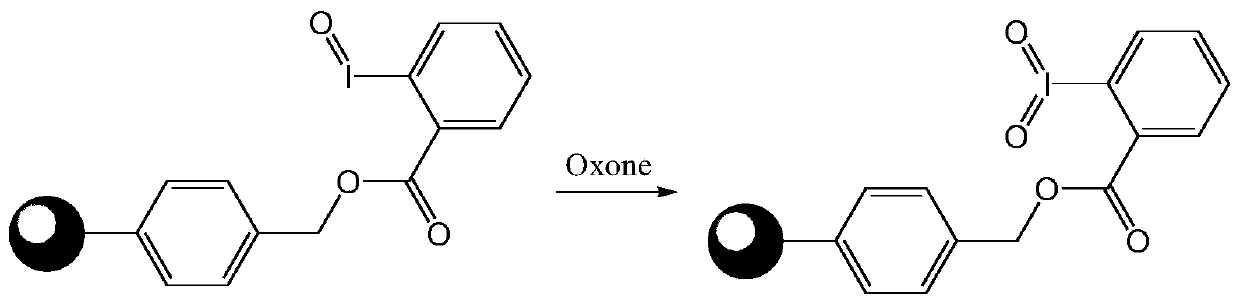

[0022] Add 363 ml of N,N-dimethylformamide, 24 grams of potassium monopersulfate (Oxone) into a reaction flask equipped with a mec...

Embodiment 2

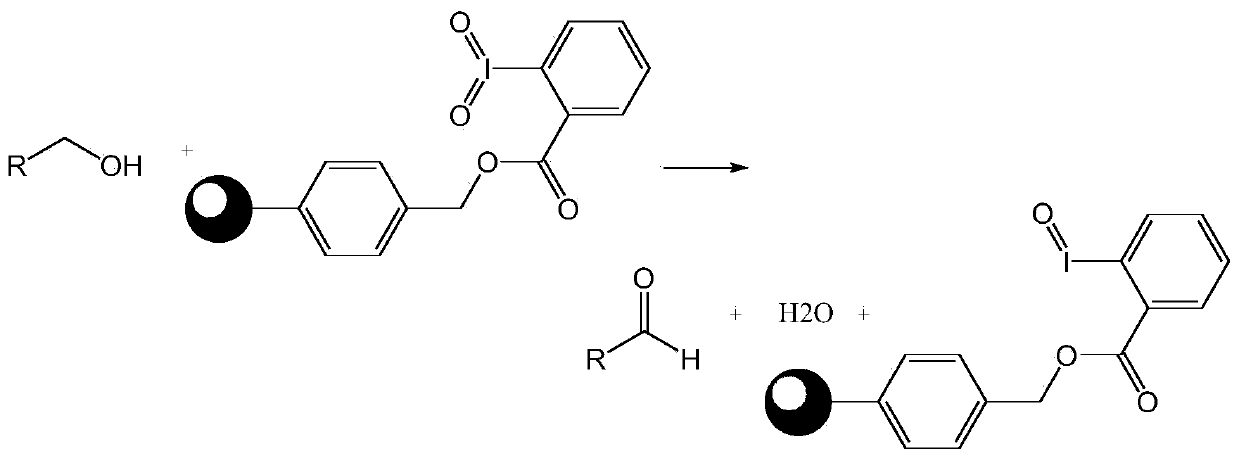

[0024] The polymer loaded oxidant containing high valence iodine prepared in the present invention is mainly used for the oxidation of alcohols, and the reaction formula between the polymer loaded oxidant containing high valence iodine and alcohol oxidation is as follows figure 2 shown. Specifically, in this embodiment, 50 ml of methylene chloride, 10 g of polymer-loaded oxidant resin and 0.8 g of benzyl alcohol were added to a reaction flask equipped with a mechanical stirrer, and stirred at room temperature for 30 minutes; gas chromatography monitored , benzyl alcohol was completely converted into benzaldehyde; filtered, the filtered resin was washed with 10 ml of dichloromethane, and the combined supernatant was concentrated to obtain 0.76 g of benzaldehyde with a purity of >98%.

Embodiment 3

[0026] The polymer loaded oxidant containing high valence iodine prepared in the present invention is mainly used for the oxidation of alcohols, and the reaction formula between the polymer loaded oxidant containing high valence iodine and alcohol oxidation is as follows figure 2 shown. Specifically, in this embodiment, 50 ml of dichloromethane, 10 g of polymer-loaded oxidant resin and 1.1 g of citronellol (molecular weight: 156) were added to a reaction flask equipped with a mechanical stirrer, and stirred at room temperature for 30 Minutes; gas chromatography monitoring, citronellol is completely converted into citronellal; filter, the filtered resin is washed with 10 ml of dichloromethane, and the combined supernatant is concentrated to obtain 0.98 g of citronellal, with a purity of >98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com