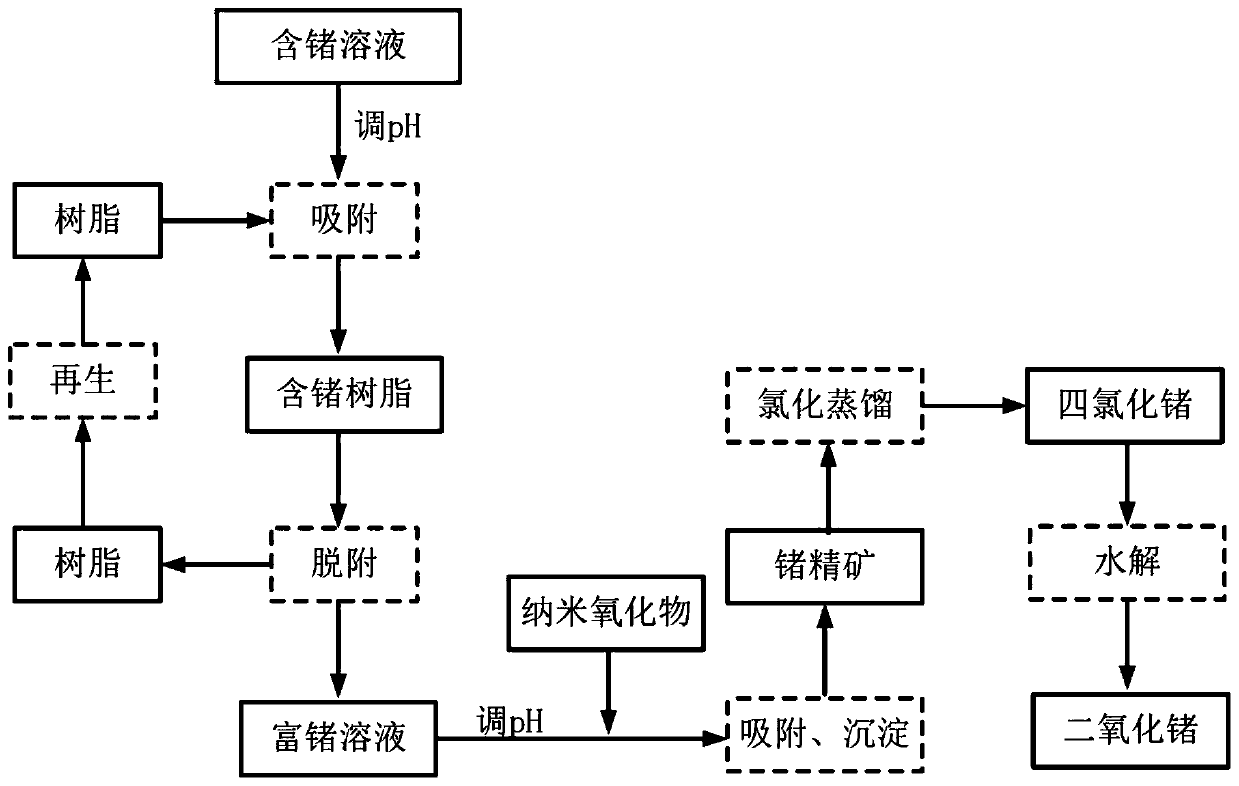

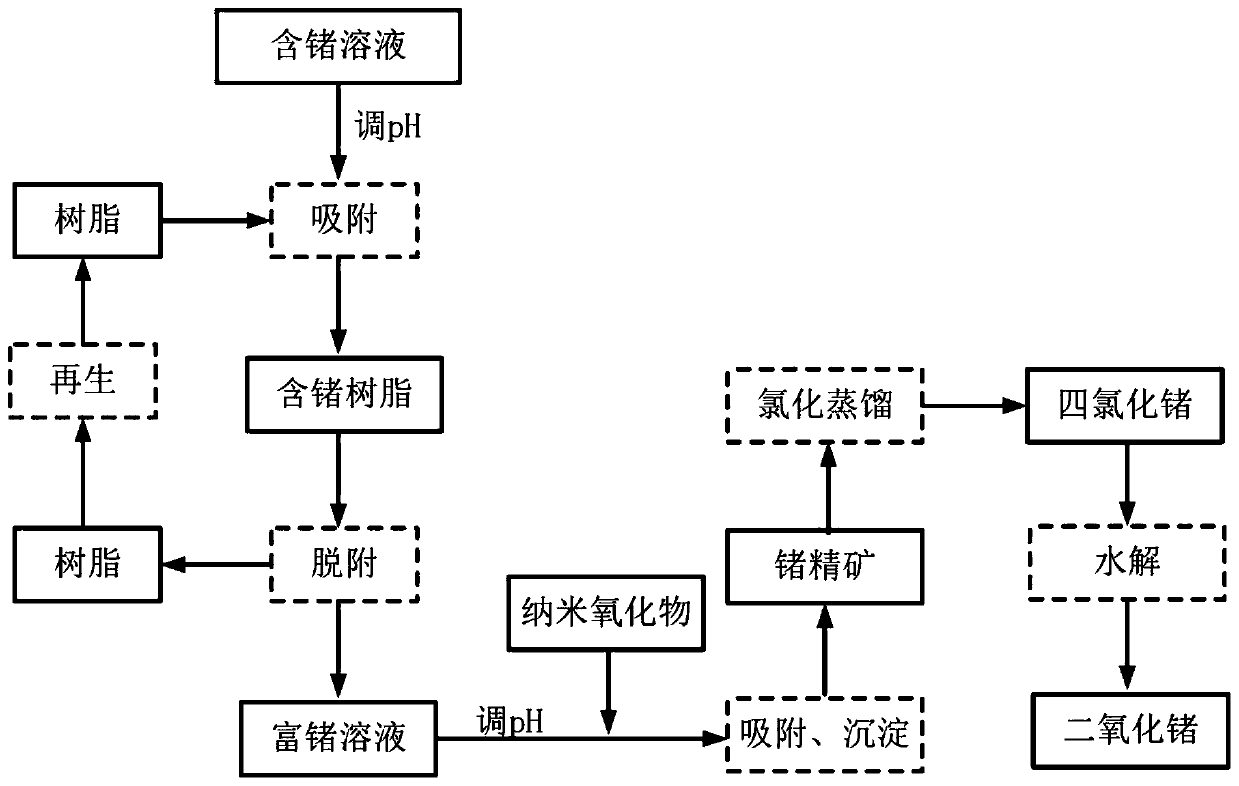

Method for recycling germanium from germanium-containing solution and application of method

A solution and resin technology, applied in the field of germanium recovery, can solve the problems of low recovery rate of germanium, high cost, low grade of germanium concentrate, etc., and achieve the effect of simple process, efficient recovery and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 contains the preparation of the anionic resin of meglumine functional group

[0030] Chloromethylation of cross-linked polystyrene microspheres: in a 2000mL four-necked flask equipped with a stirrer and a thermometer, get 100g of cross-linked polystyrene microspheres (white balls), dissolve them in 1000mL of dichloromethane, Then add 300mL of 1,4-dichloromethoxybutane (BCMB) as a chloromethylation reagent, start stirring to fully swell the white ball, and then add 0.4mol of SnCl 4 As a catalyst, react at room temperature for 10 h, filter with suction after the reaction is over, wash the resin particles with 1mol / L dilute hydrochloric acid, wash with distilled water and ethanol, and dry in vacuo to obtain chloromethylated polystyrene crosslinked microspheres (chlorine Ball) 115g.

[0031] Meglumine functionalization of chloromethylated polystyrene crosslinked microspheres: weigh 100 g of chloromethylated polystyrene crosslinked Microspheres (chlorine balls...

Embodiment 2

[0033] Measure 500 g of germanium-containing neutral liquid, adjust the pH of the solution to 11 with 5 mol / L sodium hydroxide solution, add 50 g of meglumine-containing functional group resin, and stir for 1 h. A chromatographic column is used to separate the germanium-containing resin and the solution after adsorption. Stir the resin with 100ml of deionized water for 5 minutes, replace with new 100ml of deionized water and stir again for 5 minutes, wash until neutral, and separate the resin and deionized water. Then, 100ml of 0.5M hydrochloric acid was used for desorption treatment, stirred for 1 hour, and separated by a chromatographic column to obtain a germanium-rich solution and resin. Add 5mol / L sodium hydroxide solution in the acidic germanium-rich solution, adjust the pH of the solution=8.5, use 2g of nano-calcium oxide to absorb and precipitate to obtain a germanium-containing precipitate, add 31% industrial hydrochloric acid to the germanium-containing precipitate, ...

Embodiment 3

[0035] Weigh 100 g of strongly alkaline germanium-containing solution, add 50 g of meglumine-containing functional group resin, and stir for 2 h. Solid-liquid separation to obtain germanium-containing resin and strong alkaline solution after adsorption. Wash the resin with 100ml of deionized water, soak it again with a new 100ml of deionized water, wash the resin until it is neutral. Then, 100 ml of 2M hydrochloric acid was used for desorption treatment, stirred for 2 hours, and separated by a chromatographic column to obtain a germanium-rich solution and resin. Add 5mol / L sodium hydroxide solution in the germanium-rich solution, adjust the pH of the solution=9, absorb and precipitate the germanium-rich solution with nano-magnesium oxide to obtain a germanium-containing precipitate, add 31% industrial hydrochloric acid to the germanium-containing precipitate, Distill to get germanium tetrachloride, and hydrolyze germanium tetrachloride to get germanium dioxide. After calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com