SiO2-precious metal nano composite material of core-shell structure and preparation method of SiO2-precious metal nano composite material

A technology of nano-composite material and core-shell structure is applied in the field of core-shell structure SiO2@precious metal nano-composite material and its preparation, which can solve problems such as being unfavorable to environmental protection, and achieve the effects of uniform particle size, particle size control, and short growth time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

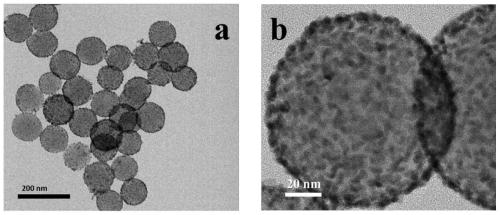

[0044] The core-shell structure SiO proposed by the present invention 2 The preparation method of @Pt nanocomposite material, method step is as follows:

[0045] S1: Preparation of Amino Silica Nanoparticles

[0046] S11: add absolute ethanol and ultrapure water into the container, and stir at room temperature for 5 minutes;

[0047] S12: Add ethyl orthosilicate to the mixed solution of S11, stir for 30 minutes, add ammonia water, and continue stirring for 2 hours;

[0048] S13: Centrifuge the solution stirred in S12, and then wash it twice with ethanol and water respectively to obtain silica nanoparticles;

[0049] S14: Disperse the silicon dioxide nanoparticles obtained in S13 in absolute ethanol, then add 3-aminopropyltriethoxysilane, heat the solution to 6°C, and reflux for 12h;

[0050] S15: Centrifuge the reaction product in S14, wash the product twice with ethanol and water respectively, and dry to obtain amino silicon dioxide nanoparticles.

[0051] S2: Generation ...

Embodiment 2

[0074] The core-shell structure SiO proposed by the present invention 2 The preparation method of @Pt nanocomposite material, method step is as follows:

[0075] S1: Preparation of Amino Silica Nanoparticles

[0076] S11: add absolute ethanol and ultrapure water into the container, and stir at room temperature for 3 minutes;

[0077] S12: Add ethyl orthosilicate to the mixed solution of S11, stir for 20 min, add ammonia water, and continue stirring for 1.5 h;

[0078] S13: Centrifuge the solution stirred in S12, and then wash it twice with ethanol and water respectively to obtain silica nanoparticles;

[0079] S14: Disperse the silica nanoparticles obtained in S13 in absolute ethanol, then add 3-aminopropyltriethoxysilane, heat the solution to 50° C., and reflux for 10 h;

[0080] S15: Centrifuge the reaction product in S14, wash the product twice with ethanol and water respectively, and dry to obtain amino silicon dioxide nanoparticles.

[0081] S2: Generation of Platinum...

Embodiment 3

[0097] The core-shell structure SiO proposed by the present invention 2 The preparation method of @Pt nanocomposite material, method step is as follows:

[0098] S1: Preparation of Amino Silica Nanoparticles

[0099] S11: add absolute ethanol and ultrapure water into the container, and stir at room temperature for 7 minutes;

[0100] S12: Add ethyl orthosilicate to the mixed solution of S11, stir for 40 minutes, add ammonia water, and continue stirring for 2.5 hours;

[0101] S13: Centrifuge the solution stirred in S12, and then wash it twice with ethanol and water respectively to obtain silica nanoparticles;

[0102] S14: Disperse the silica nanoparticles obtained in S13 in absolute ethanol, then add 3-aminopropyltriethoxysilane, heat the solution to 70°C, and reflux for 14h;

[0103] S15: Centrifuge the reaction product in S14, wash the product twice with ethanol and water respectively, and dry to obtain amino silicon dioxide nanoparticles.

[0104] S2: Generation of Pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com