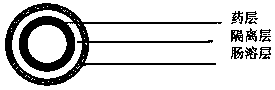

Preparation method of omeprazole enteric capsule

A technology of omeprazole enteric capsules, which is applied in the field of preparation of omeprazole enteric-coated capsules, can solve problems such as unevenness, narrow particle size distribution, and influence on drug efficacy, and achieve good toughness, handling, and water retention Effect, good drug release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: Alkalinizing agent uses disodium hydrogen phosphate instead of sodium hydroxide, because of its compatibility difference with cellulose, disodium hydrogen phosphate is prepared separately with high concentration, and added in the mixed powder in turn, both to ensure It not only improves the compatibility, but also realizes the requirement of basicity of raw materials and the viscosity of soft materials for extrusion.

[0058] The formula is as follows:

[0059]

[0060]

[0061] Preparation:

[0062] (1) Preparation of raw and auxiliary materials: weigh omeprazole, microcrystalline cellulose, mannitol, anhydrous lactose, and sodium lauryl sulfate according to the prescription amount, mix and pass through a 40-mesh sieve;

[0063] (2) Preparation of adhesive: dissolve hypromellose in purified water of the prescribed amount until the solution is clear and transparent; then add disodium hydrogen phosphate until completely dissolved;

[0064] (3) Premixin...

Embodiment 2

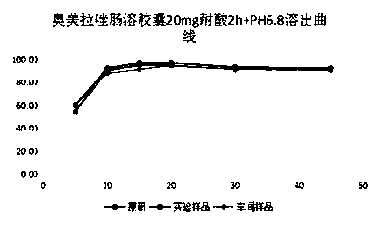

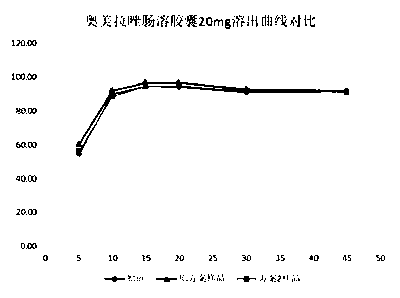

[0079]Example 2: The enteric-coated layer plasticizer is replaced by triethyl citrate, matched with glyceryl monostearate and Tween 80. This classic combination can solve the impact of polyethylene glycols on the later release, and realize A perfect substitute, reducing the adhesion of the coating.

[0080] The formula is as follows:

[0081]

[0082] Preparation:

[0083] (1) Preparation of raw and auxiliary materials: weigh omeprazole, microcrystalline cellulose, mannitol, anhydrous lactose, and sodium lauryl sulfate according to the prescription amount, mix and pass through a 40-mesh sieve;

[0084] (2) Preparation of adhesive: dissolve hypromellose in purified water of the prescribed amount until the solution is clear and transparent; then add sodium hydroxide until completely dissolved;

[0085] (3) Premixing: put the materials in step 1 into a wet granulator for premixing, set the stirring speed of the wet granulator to 60 rpm, and mix for 5 minutes;

[0086] (4) S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com