Preparation method and application of Ni-NTA modified silicon dioxide coated ferroferric oxide magnetic nano functional assembly

A technology of ferroferric oxide and magnetic nanometers, which is applied in the field of materials, can solve the problems of complex preparation process, low separation efficiency, and insufficient surface group density, and achieve the effect of simple process, improved overall performance, and a large number of separation and extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

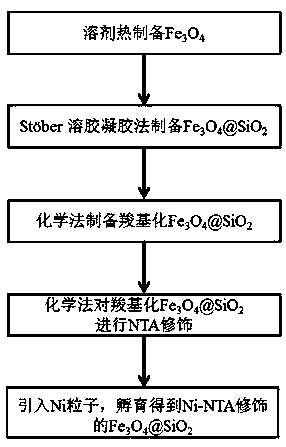

Method used

Image

Examples

Embodiment 1

[0037] (1) Fe 3 o 4 Preparation of nanoclusters:

[0038] Weigh 0.34gFeCl 3 ·6H 2 O, 0.9g NaAc 3H 2 Dissolve O in 60mL of ethylene glycol, stir at room temperature to completely dissolve the solid, and obtain a mixed solution; add the mixed solution into a 100mL stainless steel high-temperature reaction kettle embedded with polytetrafluoroethylene, react at 180°C for 8 hours, and use it after cooling Washed three times with ethanol and deionized water, separated by an external magnetic field, and freeze-dried to obtain Fe 3 o 4 nanoclusters;

[0039] Figure 5 In: (a) Fe 3 o 4 ; (b) Fe 3 o 4 @SiO 2 ; (c) Ni-NTA modified Fe 3 o 4 @SiO 2 TEM photographs of linked proteins in magnetic nanofunctional assemblies;

[0040] From Figure 5 (a) Fe can be seen in the transmission electron microscope 3 o 4 Nanoclusters are composed of many small Fe 3 o 4 Nanoparticles are assembled, and the cluster particle size is about 200nm.

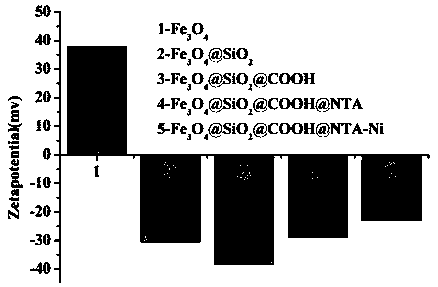

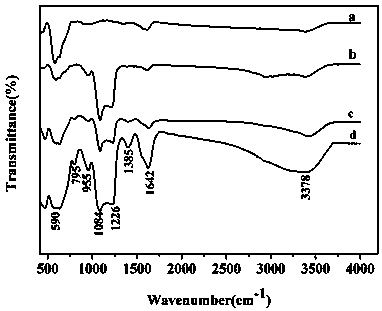

[0041] From figure 2 (1) Fe can be...

Embodiment 2

[0064] As described in Example 1, the difference is:

[0065] Step (1) Fe 3 o 4 The preparation of nanoclusters remains unchanged;

[0066] Step (2) Fe 3 o 4 @SiO 2 The preparation remains unchanged;

[0067] In step (3), 0.5 mL of sodium N-(trimethoxysilylpropyl)ethylenediaminetriacetate was added, the heating temperature was 60° C., and the heating time was 10 h;

[0068] Add 10mgEDC and 10mgNHS in step (4), add 1mg NTA, the reaction time is 48h;

[0069] Add 0.1MNiCl in step (5) 2 Aqueous solution, mixed reaction 3h.

Embodiment 3

[0071] As described in Example 1, the difference is:

[0072] Step (1) Fe 3 o 4 The preparation of nanoclusters remains unchanged;

[0073] Step (2) Fe 3 o 4 @SiO 2 The preparation remains unchanged;

[0074] In step (3), 2 mL of sodium N-(trimethoxysilylpropyl) ethylenediamine triacetate was added, the heating temperature was 70° C., and the heating time was 9 h;

[0075] Add 20mgEDC and 20mgNHS in step (4), add 2mg NA, NA-bis(carboxymethyl)-L-lysine hydrate, and the reaction time is 36h;

[0076] Add 0.5MNiCl in step (5) 2 Aqueous solution, mixed reaction 2.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com