Lip-shaped sealing ring for automobile engine rotating shaft

A lip-shaped sealing ring, automobile engine technology, applied in the field of sealing materials, can solve the problems of short service life, high production cost, complex process, etc., to improve thermal conductivity and gas barrier properties, improve mechanical strength and wear resistance, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

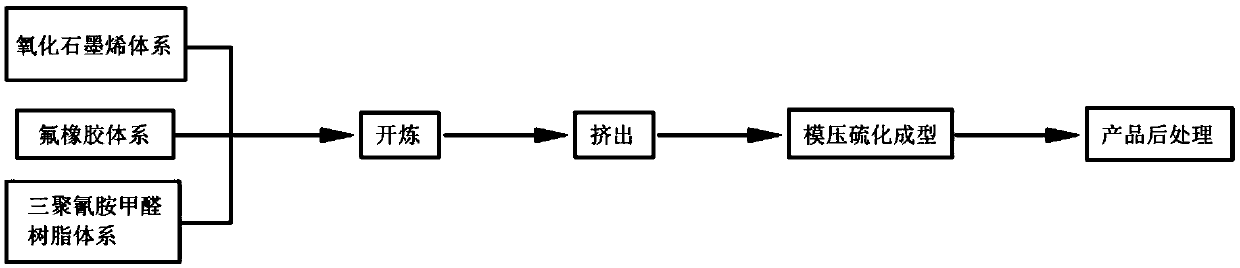

Method used

Image

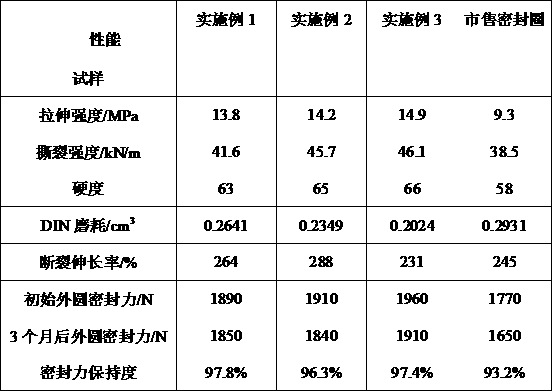

Examples

Embodiment 1

[0025] A lip seal ring for the rotating shaft of an automobile engine, the lip seal ring is composited by a fluororubber system, a melamine formaldehyde resin system and a graphene oxide system;

[0026] The fluororubber system includes the following components in parts by weight: 100 parts of fluororubber, 3.5 parts of diatomaceous earth, 10 parts of magnesium oxide, 2 parts of calcium hydroxide, 5 parts of carbon black, 1.5 parts of bisphenol AF, and 0.5 parts of BPP ;

[0027] The melamine-formaldehyde resin system includes the following components in parts by weight: 20 parts of melamine, 10 parts of paraformaldehyde, 5 parts of formaldehyde solution with a mass fraction of 37%, 3 parts of cellulose sulfonate, and 6 parts of isopropanone;

[0028] The graphene oxide system includes the following components in parts by weight: 1 part of graphene oxide, 10 parts of coupling agent, 5 parts of acetic acid solution with a mass fraction of 66.7%, and 30 parts of methyl ethyl ket...

Embodiment 2

[0040] A preparation method for a lip seal ring for a rotary shaft of an automobile engine, comprising the steps of:

[0041] Step 1: Preparation of graphene oxide system

[0042]Take 40 parts of methyl ethyl ketone and 1.8 parts of graphene oxide, mix them uniformly by ultrasonic, then add 7 parts of formaldehyde solution with a mass fraction of 37% to the mixed solution, continue to mix evenly, add 13 parts of coupling agent, and in an oil bath at 75°C , reacted for 10h, washed with deionized water and vacuum-dried after the reaction to obtain treated graphene oxide;

[0043] Step 2: Preparation of melamine formaldehyde resin system

[0044] Take 25 parts of melamine and 15 parts of paraformaldehyde into the reactor, then add 40 parts of deionized water, heat up to 55 ° C under stirring conditions, add 8 parts of formaldehyde solution with a mass fraction of 37% after mixing and use 20 % sodium hydroxide solution to adjust the pH value, control it at 8~9, then raise the te...

Embodiment 3

[0049] A preparation method for a lip seal ring for a rotary shaft of an automobile engine, comprising the steps of:

[0050] Step 1: Preparation of graphene oxide system

[0051] Take 50 parts of methyl ethyl ketone and 1.5 parts of graphene oxide, mix them uniformly by ultrasonic, then add 10 parts of formaldehyde solution with a mass fraction of 37% to the mixed solution, continue to mix evenly, add 20 parts of coupling agent, and put them in an oil bath at 75°C , reacted for 12h, washed with deionized water and vacuum-dried after the reaction to obtain treated graphene oxide;

[0052] Step 2: Preparation of melamine formaldehyde resin system

[0053] Take 30 parts of melamine and 18 parts of paraformaldehyde into the reactor, then add 50 parts of deionized water, heat up to 55 ° C under stirring conditions, add 10 parts of formaldehyde solution with a mass fraction of 37% after mixing and use 20 % sodium hydroxide solution to adjust the pH value, control it at 8~9, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com