Collagen edible film and preparation method thereof

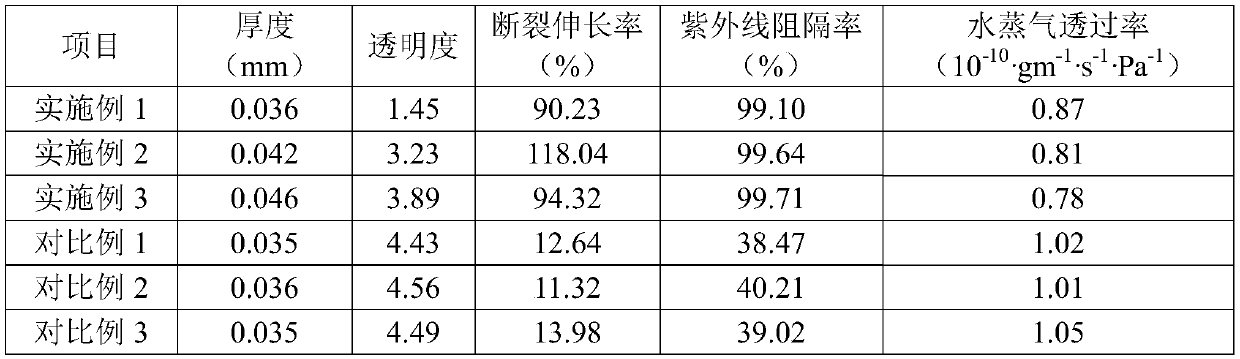

A technology of collagen and fish scale collagen, which is applied in the field of food edible film packaging, can solve the problems of changing the mechanical properties and barrier properties of the film, nutritional loss of collagen, and low elongation at break, so as to reduce the transmittance and reduce the Deterioration and damage, the effect of improving ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Preparation of film-forming solution:

[0046] S1. Preparation of fish scale collagen matrix solution: stirring and dissolving crudely extracted fish scale collagen powder in 60°C water to obtain 7.5wt% fish scale collagen matrix solution;

[0047] S2. Preparation of protocatechuic acid modified solution: stirring and dissolving protocatechuic acid powder in water to obtain 2wt% protocatechuic acid modified solution;

[0048] S3. Preparation of plasticizing solution: stirring and dissolving plasticizer glycerin in water to obtain 1wt% plasticizing solution;

[0049] S4, the preparation of modified fish scale collagen matrix film-forming liquid: the fish scale collagen matrix liquid in step S1, the protocatechuic acid improvement liquid in step S2 and the plasticizing liquid in step S3 are pressed 2:1:2 ( The v:v:v) ratio is stirred and mixed uniformly to obtain a modified fish scale collagen matrix film-forming liquid.

[0050] (2) Ultrasonic mixing and degassing:...

Embodiment 2

[0053] (1) Preparation of film-forming solution:

[0054] S1. Preparation of fish scale collagen matrix solution: stirring and dissolving crude fish scale collagen powder in 65°C water to obtain 6.25wt% fish scale collagen matrix solution;

[0055] S2. Preparation of protocatechuic acid modified solution: stirring and dissolving protocatechuic acid powder in water to obtain 3wt% protocatechuic acid modified solution;

[0056] S3, preparation of plasticizing liquid: stirring and dissolving plasticizer glycerol in water to obtain 1.25wt% plasticizing liquid;

[0057] S4, the preparation of modified fish scale collagen matrix film-forming liquid: the fish scale collagen matrix liquid in step S1, the protocatechuic acid improvement liquid in step S2 and the plasticizing liquid in step S3 are pressed 2:1:2 ( The v:v:v) ratio is stirred and mixed uniformly to obtain a modified fish scale collagen matrix film-forming liquid.

[0058] (2) Ultrasonic mixing and degassing: the modifie...

Embodiment 3

[0061] (1) Preparation of film-forming solution:

[0062] S1. Preparation of fish scale collagen matrix solution: stirring and dissolving the crudely extracted fish scale collagen powder in 65°C water to obtain a 5wt% fish scale collagen matrix solution;

[0063] S2. Preparation of protocatechuic acid modified solution: stirring and dissolving protocatechuic acid powder in water to obtain 4wt% protocatechuic acid modified solution;

[0064] S3. Preparation of plasticizing solution: stirring and dissolving plasticizer sorbitol in water to obtain 1.25wt% plasticizing solution;

[0065] S4, the preparation of modified fish scale collagen matrix film-forming liquid: the fish scale collagen matrix liquid in step S1, the protocatechuic acid improvement liquid in step S2 and the plasticizing liquid in step S3 are pressed 2:1:2 ( The v:v:v) ratio is stirred and mixed uniformly to obtain a modified fish scale collagen matrix film-forming liquid.

[0066] (2) Ultrasonic mixing and deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com