Polysiloxane hybrid quantum dot nano material, preparation method and application thereof

A polysiloxane and nanomaterial technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of poor stability, low quantum efficiency, quenching of aggregated fluorescence, etc., to overcome the poor stability, preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing polysiloxane hybrid quantum dot nanomaterials, comprising the steps of:

[0045] Take a certain amount of silane, reaction aids and solvents and mix them, and then place them in a high-pressure reactor to react at a certain reaction temperature to obtain polysiloxane hybrid quantum dots with a particle size of 1-20nm and / or 20-500nm nanomaterials.

[0046] Among them, the obtained polysiloxane hybrid quantum dot nanomaterials with a particle size of 1-20nm can be directly applied in LED light sources or QLED devices; while the particle size of the obtained polysiloxane hybrid quantum dot nanomaterials When the particle size is 20-500nm, the polysiloxane hybrid quantum dot nanomaterial with a particle size of 1-20nm is obtained through further processing by laser etching.

[0047]During the preparation process, the dosage ratio of silane, reaction aid and solvent is (0.3~3.0)ml:(0.1~1.5)g:(18~30)ml, the reaction...

Embodiment 1

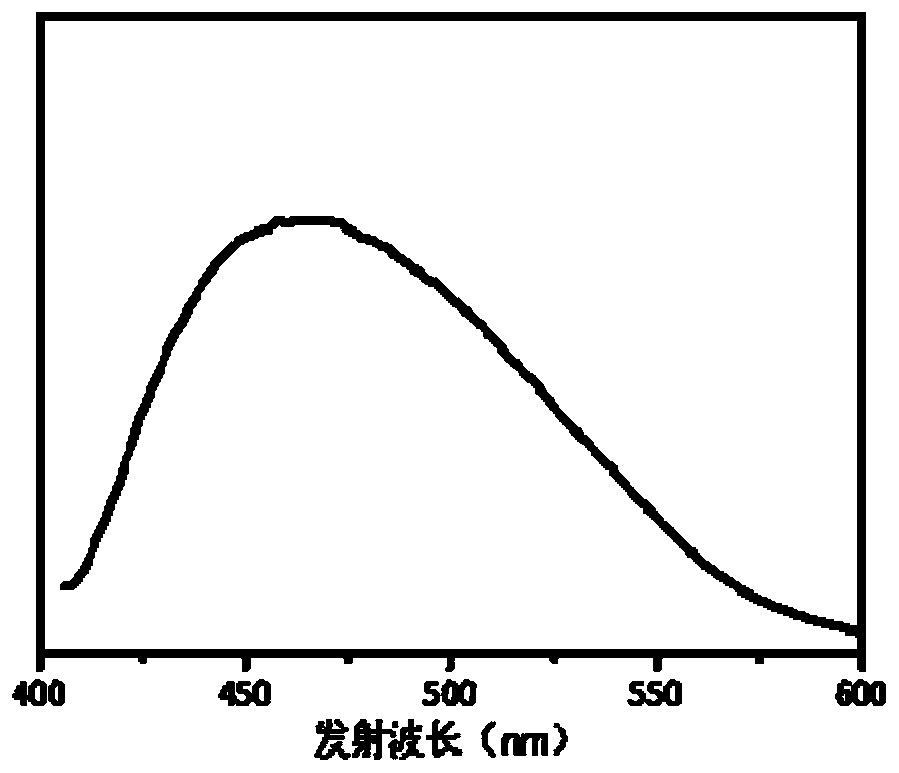

[0053] Synthesis of polysiloxane hybrid quantum dot nanomaterial 1: Prepare 0.3ml N-[3-(trimethoxysilyl)propyl]ethylenediamine, 0.2g sodium citrate and 0.1g sodium hydroxide, mix the above The reaction raw materials were added to 30ml of deionized water, stirred magnetically for 30 minutes, then transferred to an autoclave, and reacted at 230° C. for 30 hours to obtain the polysiloxane hybrid quantum dot nanomaterial 1 . After testing, the nanomaterial 1 includes quantum dots with a volume percentage of 8% and polysiloxane with a volume percentage of 92%, wherein the quantum dots detected in this embodiment are carbon quantum dots and silicon quantum dots, and the The average particle size of the nanomaterials is 10 nm. The emission spectrum of the nanomaterial 1 is as figure 1 As shown, it can be seen from the figure that the main emission peak wavelength is about 470nm, which is blue broadband emission.

[0054] Manufacturing of QLED devices: The device structure is based ...

Embodiment 2

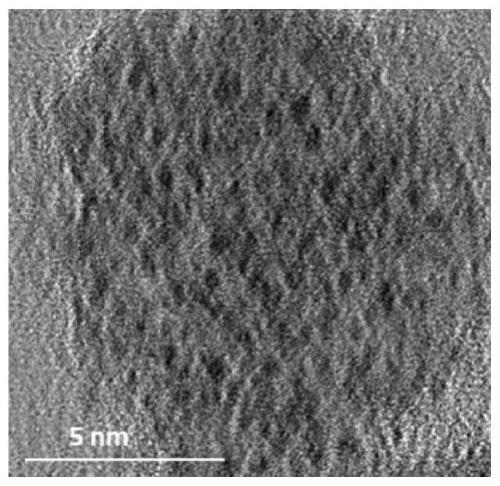

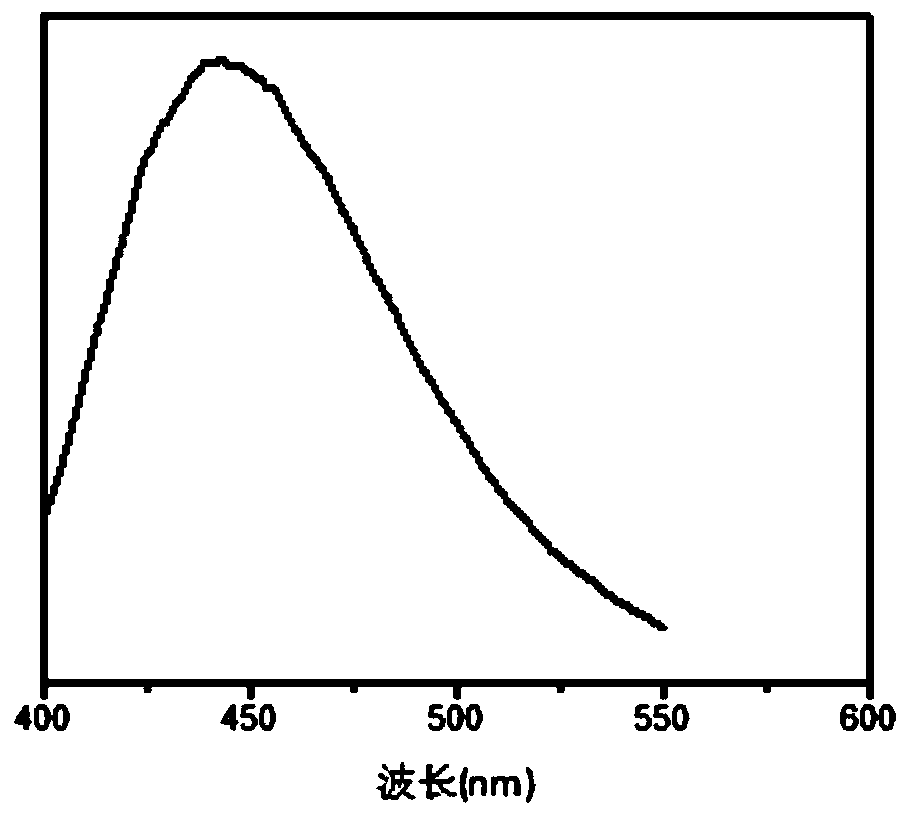

[0056] Synthesis of polysiloxane hybrid quantum dot nanomaterial 2: prepare 0.5ml 1-[3-(trimethoxysilyl)propyl]urea, 0.6g sodium citrate and EDTA-Na, and 0.2g sodium hydroxide , add the above-mentioned reaction raw materials to 30ml of a mixed solution of deionized water and ethylene glycol (the volume ratio of water to alcohol is 1:12), stir magnetically for 30 minutes, then transfer to an autoclave, and react at 300°C for 10h , the polysiloxane hybrid quantum dot nanomaterial 2 was obtained. After testing, the nanomaterial 2 includes quantum dots with a volume percentage of 20% and polysiloxane with a volume percentage of 80%, wherein the quantum dots detected in this embodiment are carbon quantum dots and silicon quantum dots, and the nanometer The average particle size of the material is 20nm, and the emission main peak wavelength is 480nm. Such as figure 2 As shown, it can be seen from the HRTEM image that the darker part is quantum dots, and its particle size is about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com