A kind of conductive paste and preparation method thereof

A technology of conductive paste and conductive materials, applied in the direction of equipment for manufacturing conductive/semiconductive layers, conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, etc., can solve the problem of no reported normal emissivity , Narrow adjustable range of resistance, expensive metal copper and other issues, to achieve the effect of low production cost, good stability and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the self-made ceramic powder prepared in this example, 8 mmol of magnesium oxide, 10 mmol of sodium silicate, 8 mmol of aluminum oxide, 9 mmol of titanium sulfate, 16 mmol of boric acid, and 32 mmol of calcium oxide were ground and mixed for 1 hour, and then ground and sieved (200 mesh) , put it into the muffle furnace and raise it to 500°C at 10°C per minute, keep it warm for two hours, and then cool down to room temperature naturally. The total amount of the prepared organic solvent is 100g, and 40g of terpineol and 60g of ethanol are prepared into a solvent system. Then add 7g of antioxidant tea polyphenols, 5g of thickener polyvinyl alcohol, 10g of self-made ceramic powder, 30g of conductive material tin powder and 15g of graphite, mix with a mixer for 3 hours until the slurry is thick. Finally, the conductive paste was screen-printed on the dielectric board with a 40-mesh screen, and the printed dielectric board was placed in a muffle furnace, raised to 400 °C a...

Embodiment 3

[0035]In the self-made ceramic powder prepared in this example, 8 mmol of magnesium oxide, 10 mmol of sodium silicate, 10 mmol of aluminum oxide, 10 mmol of titanium sulfate, 16 mmol of boric acid, and 24 mmol of calcium oxide were ground and mixed for 1 hour, and then ground and sieved (200 mesh) , put it into the muffle furnace and raise it to 500°C at 10°C per minute, keep it warm for two hours, and then cool down to room temperature naturally. The total amount of the prepared organic solvent is 100 g, and 25 g of terpineol and 75 g of ethanol are prepared into a solvent system. Then add 6g of anti-oxidant rosin, 4g of thickener polyvinyl alcohol and 6g of hydroxymethyl cellulose, take another 10g of homemade ceramic powder, 20g of conductive material tin powder and 20g of graphene, mix with a mixer for 6h until the slurry is thick . Finally, the conductive paste was screen-printed on the dielectric board with a 40-mesh screen, and the printed dielectric board was placed i...

Embodiment 4

[0037] The prior art in the table below is Example 1 in CN103274700A.

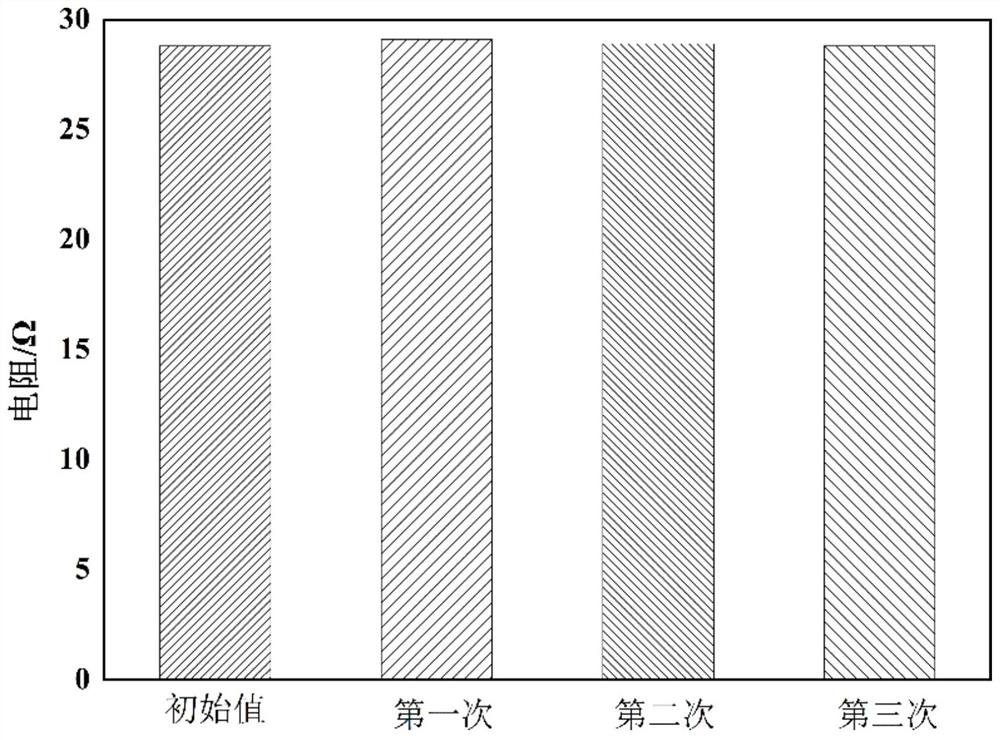

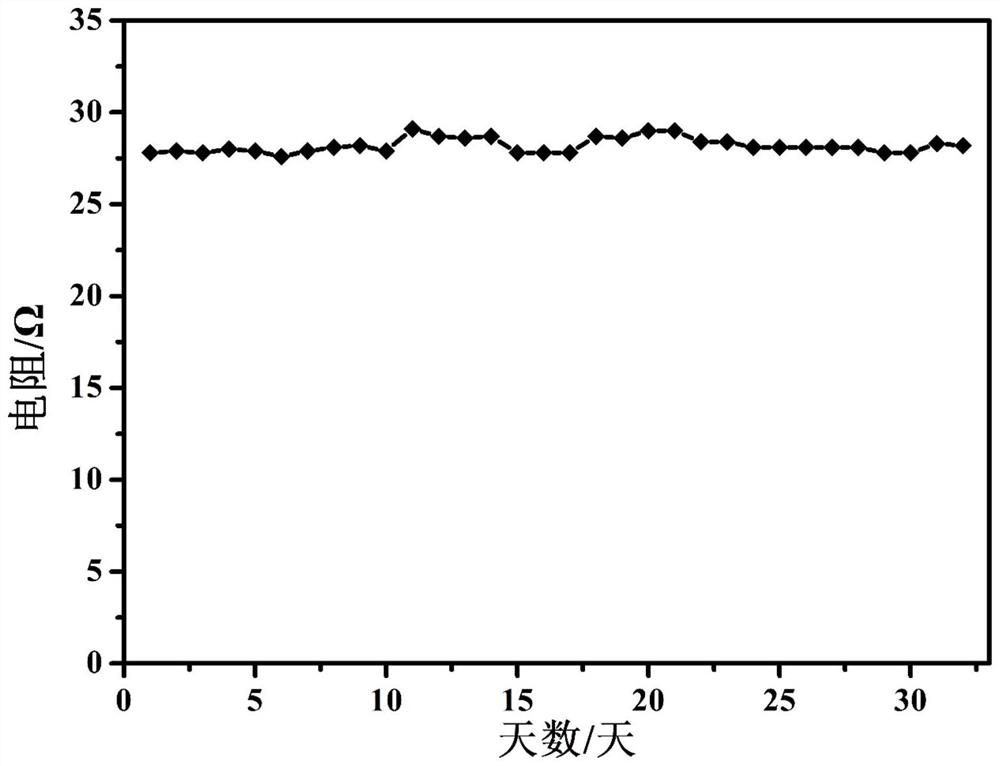

[0038] The stability test is obtained by connecting the two ends of the dielectric board with the wires of the dual-channel DC regulated power supply to pressurize 20-30V, and cooling for 10-20 minutes. Use a multimeter to test the resistance before and after pressurization, and cycle 2-6 times .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

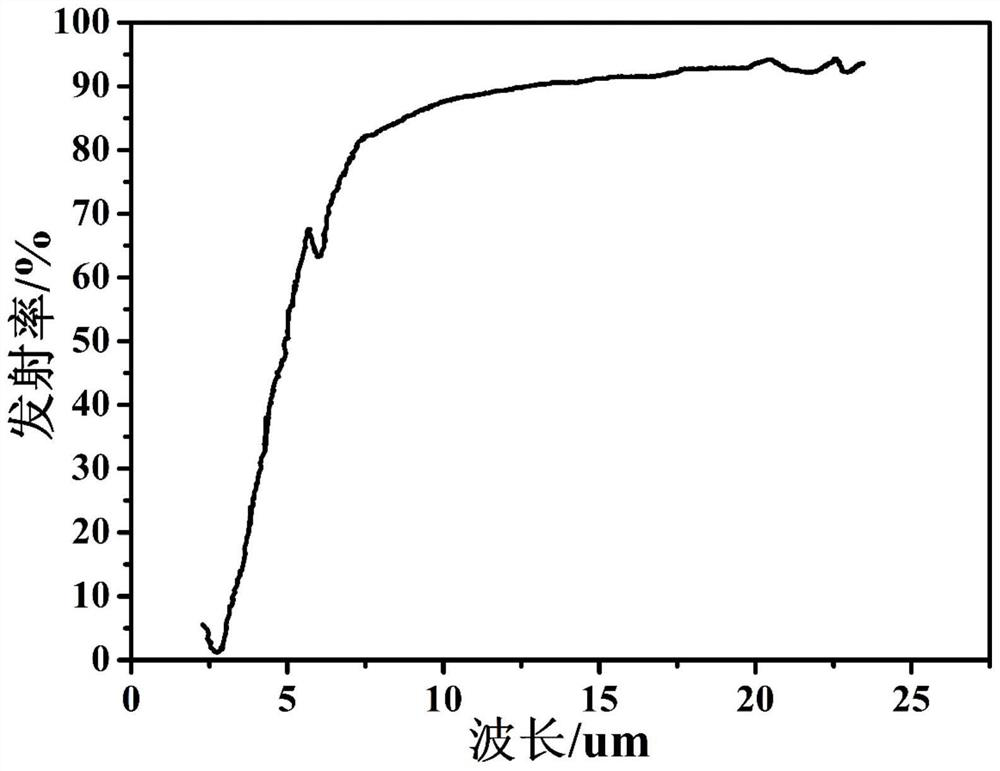

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com