High-wave-transmission green zirconia ceramic, preparation method thereof and prepared product

A technology of zirconia ceramics and yttrium-stabilized zirconia, applied in the field of high-transmittance green zirconia ceramics and its preparation, can solve problems such as difficulty in meeting market demands, and achieve the effects of good color development, good toughness and fewer defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

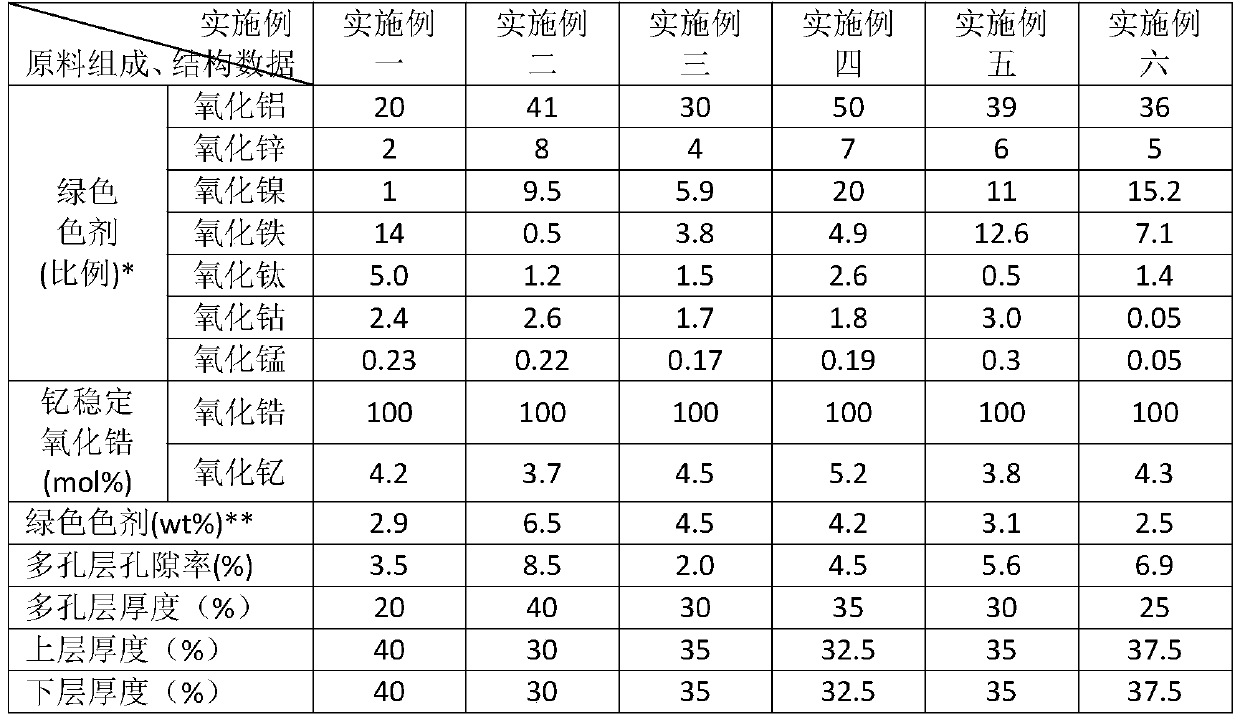

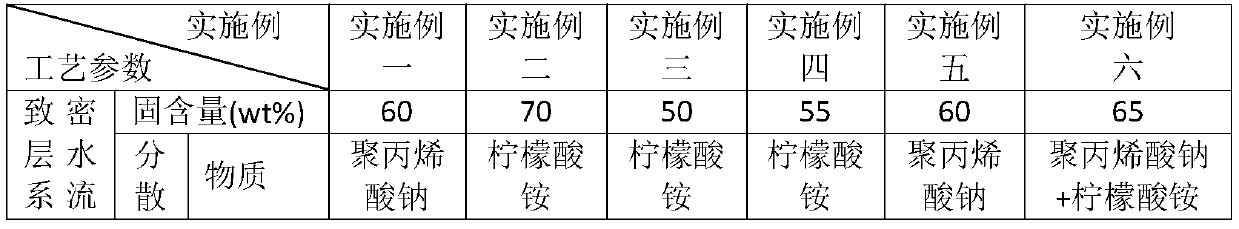

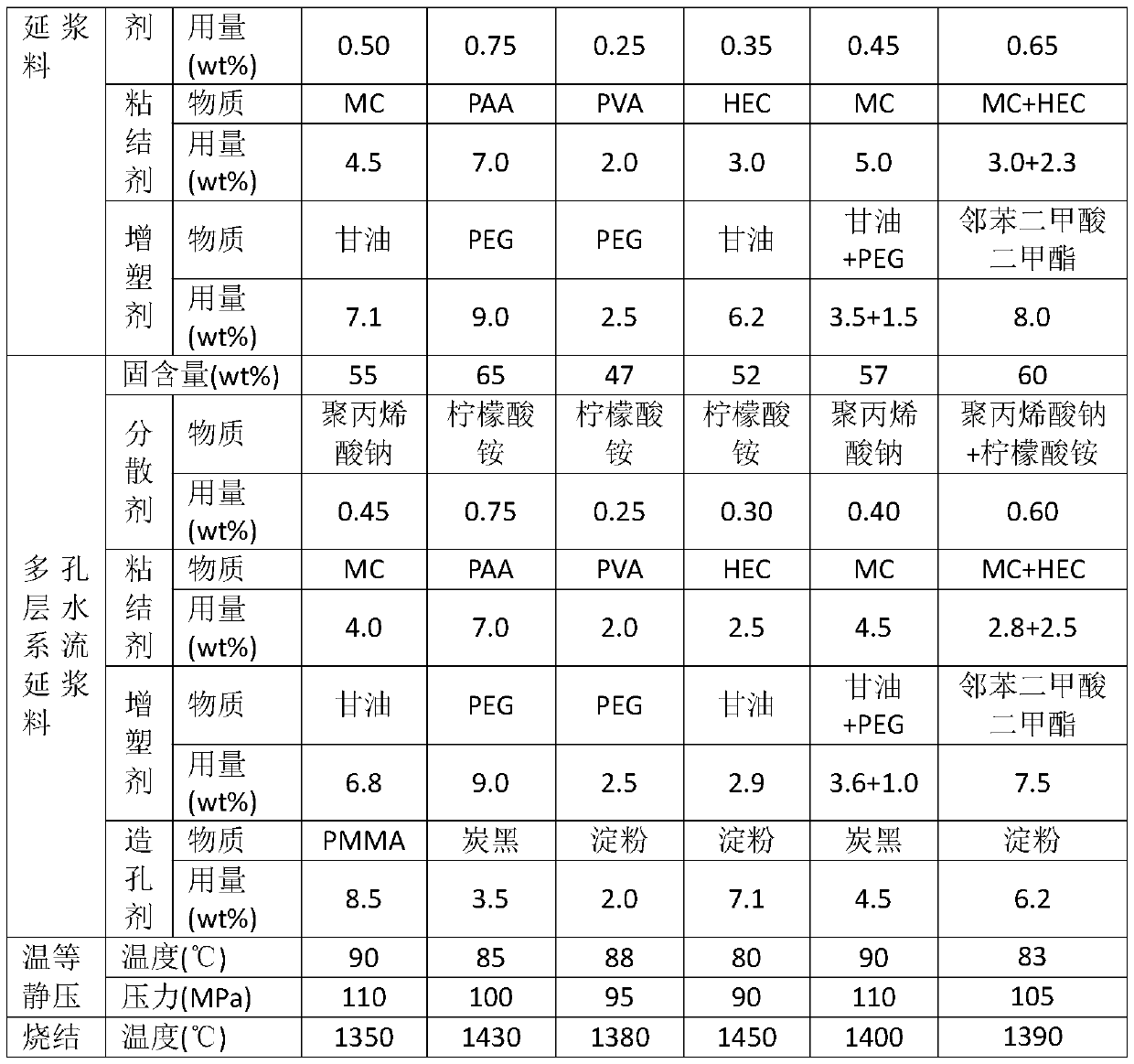

[0028] An embodiment of the present invention is a kind of high-transparency green zirconia ceramics, whose raw materials are composed of yttrium-stabilized zirconia and green toner; wherein, the amount of yttrium oxide in yttrium-stabilized zirconia is 3.5-5.5mol% of zirconia; The composition of molar ratio green toner is aluminum oxide: zinc oxide: nickel oxide: iron oxide: titanium oxide: cobalt oxide: manganese oxide=20~50:2~8:1~20:0.5~14:0.5~5:0.05 ~3:0.05~0.3; the amount of green colorant added is 2.5~6.5wt% of yttrium-stabilized zirconia; the ceramic has a sandwich gradient composite structure, the upper and lower layers are dense layers, and the thickness accounts for 30~40% of the total ceramic thickness respectively The middle layer is a porous layer with a porosity of 2-8.5% and a thickness accounting for 20-40% of the total thickness of the ceramic. The raw material composition and structural data of each embodiment are as shown in Table 1.

[0029] Table 1 The ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com