A kind of preparation method of high-efficiency IBC battery

A battery and high-efficiency technology, applied in the field of solar cells, can solve the problems of unguaranteed A-grade product rate, increased production cost, cumbersome production process, etc., and achieves excellent surface flatness, improved tightness, and good corrosion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

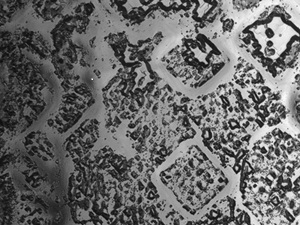

Image

Examples

Embodiment 1

[0030] A preparation method of high-efficiency IBC battery, comprising the following steps:

[0031] a. A 2 μm pyramid is formed on the surface of the n-type silicon wafer after texturing, and one side is polished with lye, the concentration of lye is 25wt%, and the polishing temperature is 70°C;

[0032] b. Boron diffusion is performed on both sides of the polished silicon wafer. After boron diffusion, the surface resistance of the silicon wafer is 110Ω / sq, and the surface concentration of boron is 1e19cm -3 , the junction depth of the pn junction is 1.5 μm, a silicon nitride film is grown on the polished surface, the thickness of the silicon nitride film is 120 nm, and the refractive index is 2.7;

[0033] c. Laser removal of borosilicate glass and silicon nitride film on the polished surface, with a line width of 150 μm;

[0034] d. After the silicon nitride film is removed by laser, the silicon wafer is etched in lye and auxiliaries, the volume ratio of auxiliaries and ly...

Embodiment 2

[0042] A preparation method of high-efficiency IBC battery, comprising the following steps:

[0043] a. A 1 μm pyramid is formed on the surface of the n-type silicon wafer after texturing, and one-sided polishing is performed with lye, the concentration of lye is 5wt%, and the polishing temperature is 60°C;

[0044] b. Boron diffusion is performed on both sides of the polished silicon wafer. After boron diffusion, the surface resistance of the silicon wafer is 80Ω / sq, and the surface concentration of boron is 1e19cm -3 , the junction depth of the pn junction is 500nm, a silicon nitride film is grown on the polished surface, the thickness of the silicon nitride film is 60nm, and the refractive index is 1.8;

[0045] c. Laser removal of borosilicate glass and silicon nitride film on the polished surface, with a line width of 100 μm;

[0046] d. After the silicon nitride film is removed by laser, the silicon wafer is etched in lye and auxiliaries, the volume ratio of auxiliaries...

Embodiment 3

[0054] A preparation method of high-efficiency IBC battery, comprising the following steps:

[0055] a. After the n-type silicon wafer is textured, a 3 μm pyramid is formed on the surface, and one side is polished with lye, the concentration of lye is 35wt%, and the polishing temperature is 80°C;

[0056] b. Boron diffusion is performed on both sides of the polished silicon wafer. After boron diffusion, the surface resistance of the silicon wafer is 130Ω / sq, and the surface concentration of boron is 1e19cm -3 , the junction depth of the pn junction is 1.5 μm, a silicon nitride film is grown on the polished surface, the thickness of the silicon nitride film is 140 nm, and the refractive index is 3.1;

[0057] c. Laser removal of borosilicate glass and silicon nitride film on the polished surface, with a line width of 250 μm;

[0058] d. After the silicon nitride film is removed by laser, the silicon wafer is etched in lye and auxiliaries, the volume ratio of auxiliaries and ly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com