Preparation and application of (TiO2-ZrO2-SiO2)@inverse opal structure SiO2 catalyst

An anti-opal structure and catalyst technology, applied in the field of inorganic non-metallic materials, can solve the problems of TiO2 grain growth, influence on crystallinity, pore size shrinkage, etc., and achieve good photocatalytic degradation performance, improved efficiency, and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

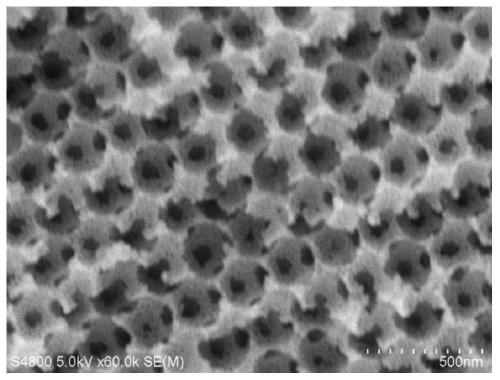

[0028] A (TiO 2 -ZrO 2 -SiO 2 )@inverse opal structure SiO 2 Composite photocatalyst preparation process, the specific process is as follows:

[0029] Step 1: Inverse Opal SiO 2 preparation. Measure 2 mL of tetraethyl orthosilicate, and then according to the volume ratio of each raw material: tetraethyl orthosilicate: absolute ethanol: deionized water: ammonia water = 2:8:5:0.1, mix the raw materials and continue to stir until they are mixed After the solution is clarified, SiO 2 Sol. Measure a certain amount of SiO 2 Sol and polystyrene emulsion mixed. The volume ratio of the two is SiO 2 Sol:polystyrene emulsion=1:3. Pour it into a crystallization dish after ultrasonication for 30 minutes, and place it in a 40°C oven for deposition. Finally, the inverse opal structure SiO can be obtained by removing the polystyrene template 2 spare.

[0030] Step 2: preparation of titanium silicon zirconium sol. Under the condition of continuous magnetic stirring, dissolve zircon...

Embodiment 2

[0037] A (TiO 2 -ZrO 2 -SiO 2 )@inverse opal structure SiO 2 The preparation process of the composite photocatalyst is the same as in Example 1 except that the immersion time is different.

[0038] In this embodiment: the immersion time is 1h.

Embodiment 3

[0040] A (TiO 2 -ZrO 2 -SiO 2 )@inverse opal structure SiO 2 Composite photocatalyst preparation process, except that heat treatment temperature is different, all the other are the same as embodiment 1.

[0041] In this embodiment: the heat treatment temperature is 700°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com