Ultrathin cross-linked composite enhanced polymer anion exchange membrane and preparation method and application thereof

A composite reinforcement, polymer technology, used in fuel cells, electrochemical generators, electrical components, etc., can solve the problem that low-grade secondary amines cannot be highly cross-linked with polymer backbones, there is little room for improvement of membrane stability, and polymer substrates It contains ether bonds and other problems to achieve excellent dimensional stability and chemical stability, improve computer efficiency and dimensional stability, and simplify the film-making process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

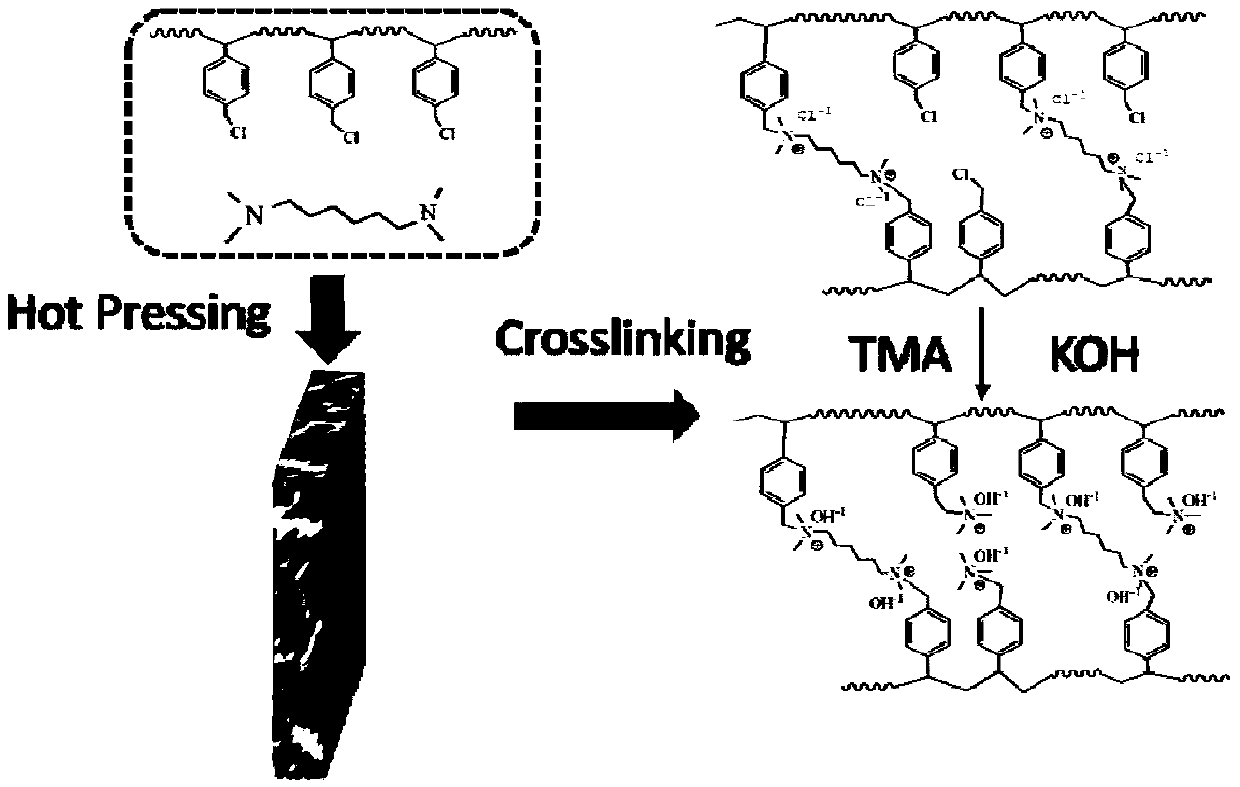

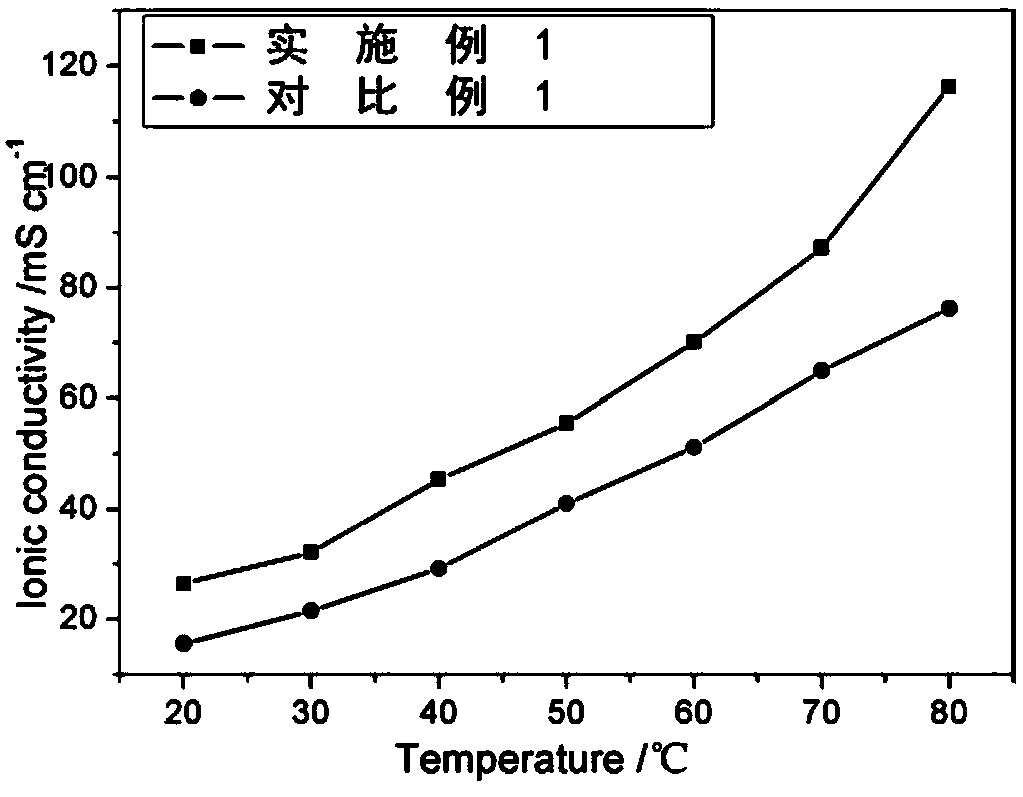

[0035] Dissolve polyvinylbenzyl chloride with molecular weight Mn≈130000 in N-methylpyrrolidone (NMP) at a concentration of 2g / mL, stir at room temperature for 1 hour, and then add crosslinking agent N,N,N' into the solution , N'-tetramethyl-1,6-hexanediamine (TMHDA), stirred at room temperature for 5 seconds to obtain a casting solution; the porous PE base film (PE, thickness 10μm, porosity 45%, average pore diameter 0.1-0.3 μm) on the peel-off polyester sheet, take a certain amount of casting liquid and spread it on the base film, and cover the surface with a layer of peel-off polyester sheet to form a "sandwich" structure, and use the flat plate to drive out the air bubbles, and scrape The coating is smooth; the cast film plate with a "sandwich" structure is sandwiched between the graphite plates, and placed on an 80°C hydraulic press for 0.5 hours, with a pressure of 2MPa. After removal, the membrane was peeled off from the polyester sheet to obtain the crosslinked and qua...

Embodiment 2

[0041] Dissolve polystyrene-ethylene-butylene-styrene (SEBS) with molecular weight Mn≈130000 in N,N-dimethylacetamide (DMAc) at a concentration of 1 g / mL, stir at room temperature for 1 hour, and then Add the cross-linking agent N,N,N',N'-tetramethylmethylenediamine (TMMDA) into the solution, stir at room temperature for 300 seconds to obtain the casting solution; the porous polytetrafluoroethylene porous membrane (PTFE, thickness 5 μm, Porosity 30-60%, average pore diameter 0.5μm). Spread it on the peel-off polyester sheet, take a certain amount of casting liquid and spread it on the base film, and then cover the surface with a layer of peel-off polyester sheet to form a "sandwich" structure, and use the flat plate to drive out the air bubbles, and scrape it evenly ; Sandwich the cast-film plate with the “sandwich” structure between the graphite plates, place it on a hydraulic press at 90°C for 0.2 hours, and press at a pressure of 4 MPa. After removal, the membrane was peel...

Embodiment 3

[0045] Dissolve chloromethylated styrene-ethylene-butylene block copolymer (SEBS) with a molecular weight of Mn≈330000 in chloroform at a concentration of 5g / mL, stir at room temperature for 12 hours, and then add cross-linking N, N, N', N'-tetramethylethylenediamine (TMEDA), stirred at room temperature for 200 seconds to obtain a casting solution; the porous PE base film (PE, thickness 10 μm, porosity 45%, average pore diameter 0.1 ~0.3μm) on the peel-off polyester sheet, take a certain amount of casting liquid and spread it on the base film, and then cover the surface with a layer of peel-off polyester sheet to form a "sandwich" structure, and use the flat plate to drive out the air bubbles, And scrape it flat; sandwich the cast film plate with "sandwich" structure between graphite plates, place it on a 150°C hydraulic press for 1 hour, and press at a pressure of 3MPa. After removal, the membrane was peeled off from the polyester sheet to obtain the crosslinked and quaterniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com