Method for synthesizing methyl propionate through homogeneous hydrogen esterification of ethylene

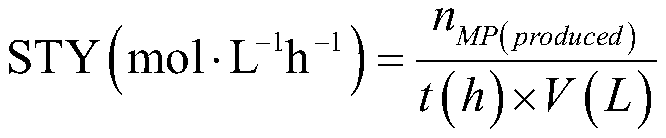

A technology for methyl propionate and chemical synthesis, which is applied in the field of homogeneous hydrogen esterification of ethylene to synthesize methyl propionate, can solve the problems of low carbonyl space-time yield, low reaction activity, poor catalyst stability and the like, and achieves improved reaction activity and selectivity, improved space-time yield, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Be that in the 0.5L titanium material autoclave (GCF500 type) in volume, add palladium acetate 0.15g successively (palladium concentration is 300ppm, and here palladium concentration refers to the total mass of reaction system as basis, the content of palladium element in the palladium main catalyst Concentration, the same below), cocatalyst ruthenium trichloride 0.02g, p-toluenesulfonic acid 2.0g, bisdiphenylphosphine methane monoxide monosulfide 0.29g, methanol 200.0g and solvent water 16.0g, the total weight of the reaction solution It is 218.46g, the molar ratio of metal ion in palladium main catalyst and metal ion promoter is 7:1, the molar ratio of organophosphorus compound and palladium main catalyst is 1:1, and the molar ratio of ethylene and carbon monoxide is 1:1. The stirring speed was 350rpm, the reaction temperature was maintained at 80°C, the reaction pressure was 3.0MPa, and the reaction time was 90 minutes. The sample was taken when the reaction time was ...

Embodiment 2

[0042] To volume is 0.5L titanium autoclave, add palladium chloride 0.12g successively (palladium concentration is 300ppm), cocatalyst ruthenium trichloride 0.02g, p-toluenesulfonic acid 2.0g, bisdiphenylphosphine methane oxide one Sulphide 0.29g, methanol 200.0g and solvent water 16.0g, reaction solution gross weight is 218.43g, the mol ratio of metal ion in palladium main catalyst and metal ion cocatalyst is 7:1, the molar ratio of organophosphorus compound and palladium main catalyst The ratio is 1:1, and the molar ratio of ethylene to carbon monoxide is 1:1. The stirring speed was 350rpm, the reaction temperature was kept at 80°C, the reaction pressure was 3.0MPa, and the reaction time was 90 minutes, the sample was taken. The result was calculated as ethylene, the selectivity to methyl propionate was 95.0%, and the carbonyl space-time yield was 14.02mol L -1 h -1 .

Embodiment 3

[0044] To a volume of 0.5L titanium autoclave, add palladium acetate 0.15g (palladium concentration is 300ppm), procatalyst ruthenium acetate 0.04g, p-toluenesulfonic acid 2.0g, bis-diphenylphosphine methane monoxide-sulfide 0.29g g, methanol 200.0g and solvent water 10.0g, the total weight of the reaction solution is 212.48g, the mol ratio of the metal ion in the palladium main catalyst and the metal ion cocatalyst is 5:1, and the mol ratio of the organophosphorus compound and the palladium main catalyst is 1 :1, the molar ratio of ethylene to carbon monoxide is 1:1. The stirring speed was 350rpm, the reaction temperature was maintained at 80°C, the reaction pressure was 3.0MPa, and the reaction time was 90 minutes, the sample was taken. The result was calculated as ethylene, the selectivity to methyl propionate was 95.0%, and the carbonyl space-time yield was 13.63mol L -1 h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com