FeCo reticular structure nano material constructed by nanowires and preparation method and application of FeCo reticular structure nano material

A network structure, nanomaterial technology, applied in the analysis of materials, material electrochemical variables, material analysis by electromagnetic means, etc., can solve the problems of high cost, complex preparation, high energy consumption, and achieve low cost, high sensitivity, Strong anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

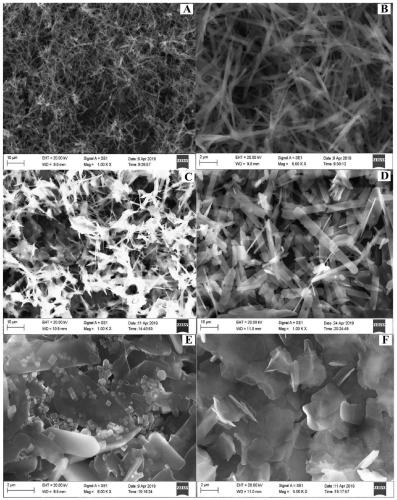

[0038] Preparation of FeCo network structure nanomaterials constructed by embodiment 1 nanowires

[0039] Add 0.016g of potassium ferricyanide and 0.023g of cobalt chloride hexahydrate into a mixed solution consisting of 5mL of water and 12.5mL of ethylenediamine, and dissolve after magnetic stirring for 1 minute;

[0040] Transfer the dissolved mixed solution to a polytetrafluoroethylene stainless steel reaction kettle, conduct a hydrothermal reaction at 80°C for 24 hours, centrifuge after natural cooling, wash with water and ethanol for several times, and dry under vacuum at 60°C FeCo network structure nanomaterials constructed by nanowires were obtained.

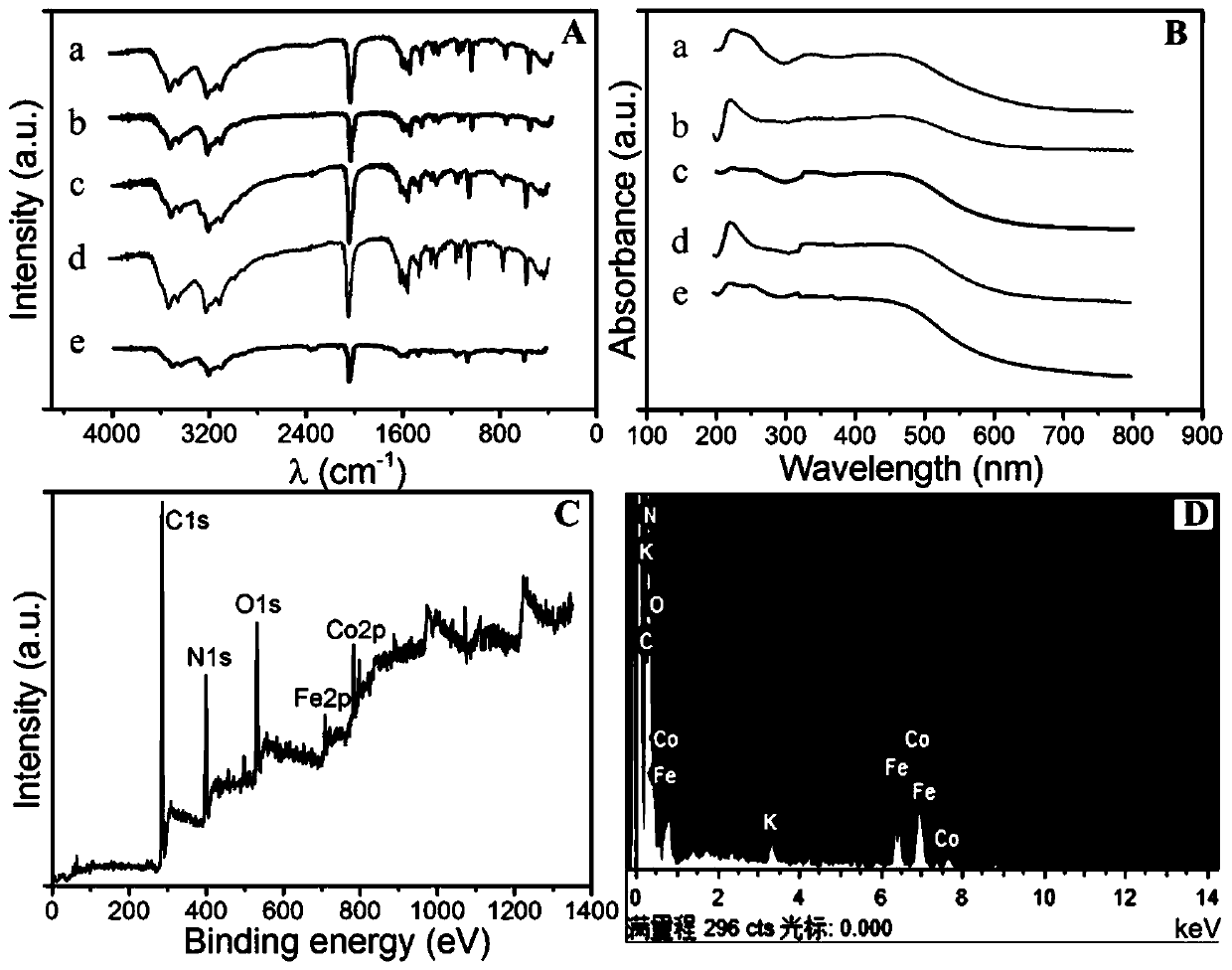

[0041] In order to illustrate the application performance of the FeCo network nanomaterials constructed by the nanowires prepared in the present invention, four other FeCo materials with different shapes were synthesized by a similar synthesis method for comparison of application performance. The shapes of the four materi...

Embodiment 2

[0058] Example 2 Preparation of FeCo Network Structure Nanomaterial Modified Electrode Constructed by Nanowires

[0059] (1) Take a glassy carbon electrode with a diameter of 3 mm, wash the glassy carbon electrode with clear water, and in the presence of an appropriate amount of Al with a particle size of 0.05 μm 2 o 3 The powder is ground in the way of drawing 8, polished 60 times, washed with deionized water, then ultrasonically washed with dilute nitric acid, acetone and deionized water, and dried under infrared light to obtain the pretreated glassy carbon electrode;

[0060] (2) Take 1.2 mg of the FeCo network structure nanomaterial constructed by the nanowires described in Example 1 and disperse it in 1 mL of N,N-dimethylformamide solvent for 20 minutes by ultrasonic to obtain an electrode material modification solution;

[0061] (3) Take 3 μL of the electrode material dispersion liquid and apply it on the surface of the pretreated glassy carbon electrode, and after dry...

Embodiment 3

[0063] The detection performance of the FeCo network nanomaterial modified electrode constructed by the embodiment 3 nanowires

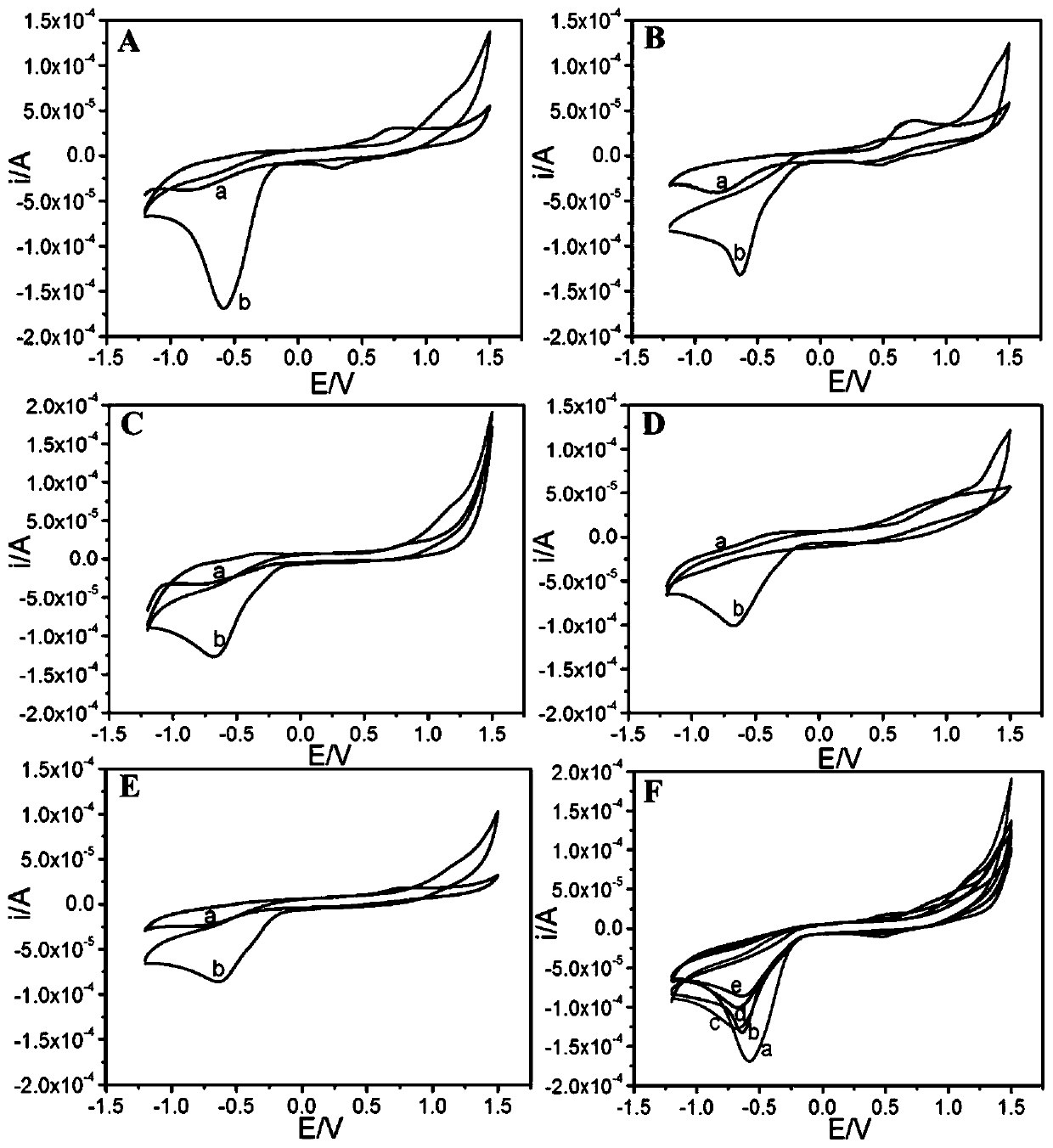

[0064] In this example, each modified electrode prepared in Example 2 was used as the experimental object, and a three-electrode system was formed with a platinum auxiliary electrode and a saturated calomel reference electrode, and the electrochemical performance was performed by connecting to an electrochemical workstation (Shanghai Chenhua CHI660D). detection.

[0065] (1) Comparison of electrocatalytic reduction performance of different electrodes for hydrogen peroxide

[0066] In order to more intuitively reflect the electrocatalytic reduction performance of the FeCo network structure nanomaterial modified electrode constructed by the nanowires prepared by the present invention to hydrogen peroxide, each modified electrode was placed in the blank bottom solution (a) and the solution containing 8mmol / In L hydrogen peroxide bottom solution (b) me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com