Anti-radiation anticorrosive coating and preparation method thereof

An anti-corrosion coating and anti-radiation technology, applied in anti-corrosion coatings, radiation-absorbing coatings, epoxy resin coatings, etc., can solve the problems of anti-radiation and anti-corrosion performance, and achieve excellent anti-radiation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

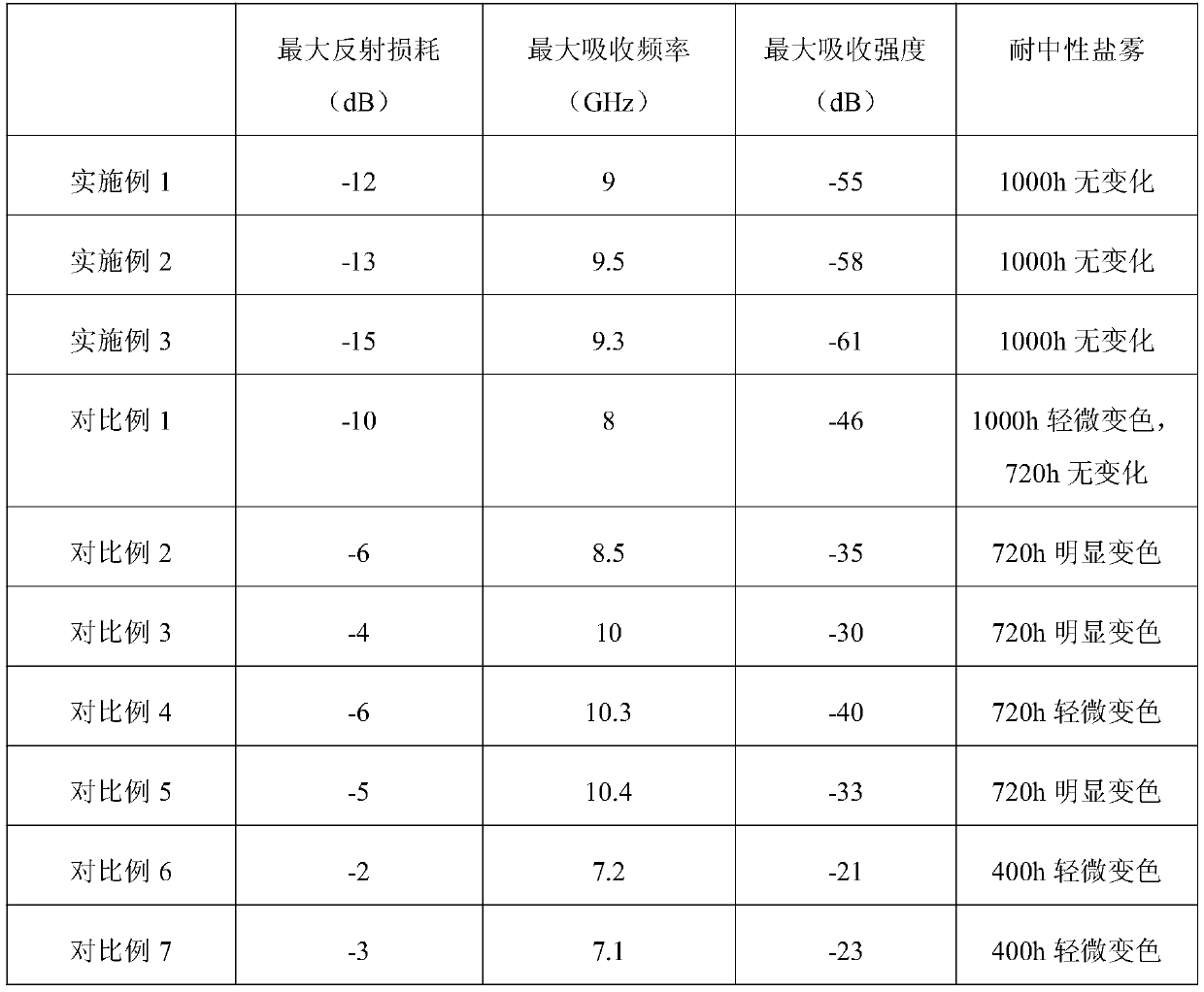

Examples

Embodiment 1

[0032] A preparation method of anti-radiation anticorrosion paint, in parts by weight, first stir and mix 0.5 parts of thickener and 15 parts of deionized water, then add 100 parts of melamine formaldehyde resin, and disperse evenly to obtain component A; then 2 1 part of dispersant, 0.3 part of defoamer, 80 parts of arachidonic acid modified epoxy resin, 8 parts of propylene glycol methyl ether acetate and 10 parts of deionized water are mixed evenly, and then 10 parts of organic modified nano powder are added to disperse evenly , to obtain component B; finally, component A and component B are stirred and mixed, and matured to obtain the above-mentioned anti-radiation anticorrosion coating; wherein, the organic modified nanometer powder is first mixed with 1 part of three-dimensional flower-shaped Cobalt tetroxide is mixed with 5 parts of helical nano carbon fiber to obtain nano powder, and then 3 parts of polyaniline are loaded on the surface of nano powder.

[0033] The thi...

Embodiment 2

[0048] A preparation method of anti-radiation anticorrosion paint, in parts by weight, first stir and mix 0.8 parts of thickener and 10 parts of deionized water, then add 100 parts of melamine formaldehyde resin, and disperse evenly to obtain component A; then 3 parts 1 part of dispersant, 0.2 part of defoamer, 90 parts of arachidonic acid modified epoxy resin, 5 parts of propylene glycol methyl ether acetate and 20 parts of deionized water and mix well, then add 8 parts of organic modified nano powder, and disperse evenly , to obtain component B; finally, component A and component B are stirred and mixed, and matured to obtain the above-mentioned anti-radiation anticorrosion coating; wherein, the organic modified nanometer powder is first mixed with 1 part of three-dimensional flower-shaped Cobalt tetroxide is mixed with 7 parts of helical nano carbon fiber to obtain nano powder, and then 2 parts of polyaniline are loaded on the surface of nano powder.

[0049] The thickener ...

Embodiment 3

[0064] A preparation method of anti-radiation anticorrosion paint, in parts by weight, first stir and mix 0.7 parts of thickener and 12 parts of deionized water, then add 100 parts of melamine formaldehyde resin, and disperse evenly to obtain component A; then 2.5 parts 1 part of dispersant, 0.25 part of defoamer, 85 parts of arachidonic acid modified epoxy resin, 6 parts of propylene glycol methyl ether acetate and 15 parts of deionized water are mixed evenly, and then 9 parts of organic modified nano powder are added to disperse evenly , to obtain component B; finally, component A and component B are stirred and mixed, and matured to obtain the above-mentioned anti-radiation anticorrosion coating; wherein, the organic modified nanometer powder is first mixed with 1 part of three-dimensional flower-shaped Cobalt tetroxide is mixed with 6 parts of helical nano-carbon fibers to obtain nano powder, and then 2.5 parts of polyaniline are loaded on the surface of the nano powder.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com