Polyacrylamide/chromium gel normal-temperature static gel breaker and preparation method thereof

A technology of polyacrylamide and gel breaker, which is applied in the fields of chemical instruments and methods, earthwork drilling, wellbore/well parts, etc. It can solve the problems of short lasting effect, difficult gel breaking effect, and immature use, etc., and achieves Increase the radius of action, improve the effect of breaking the glue, and the effect of breaking the glue faster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

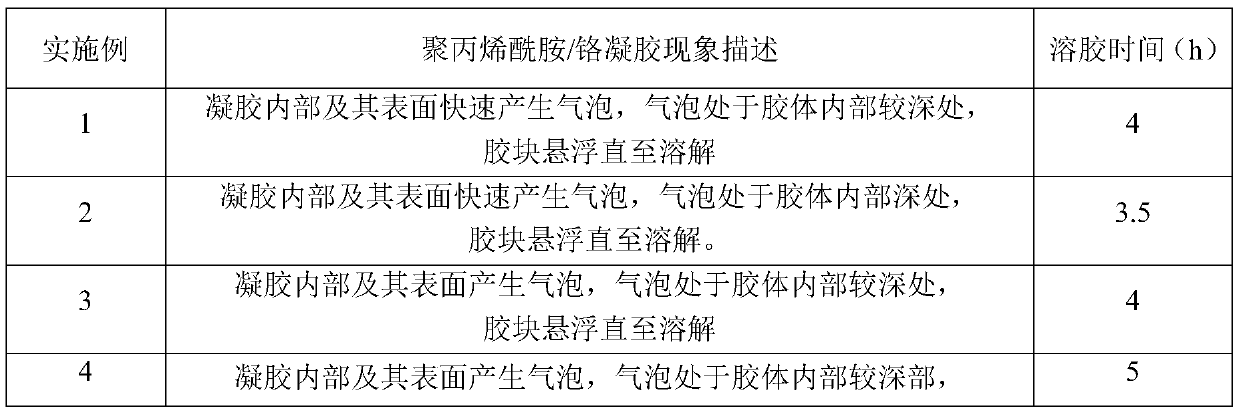

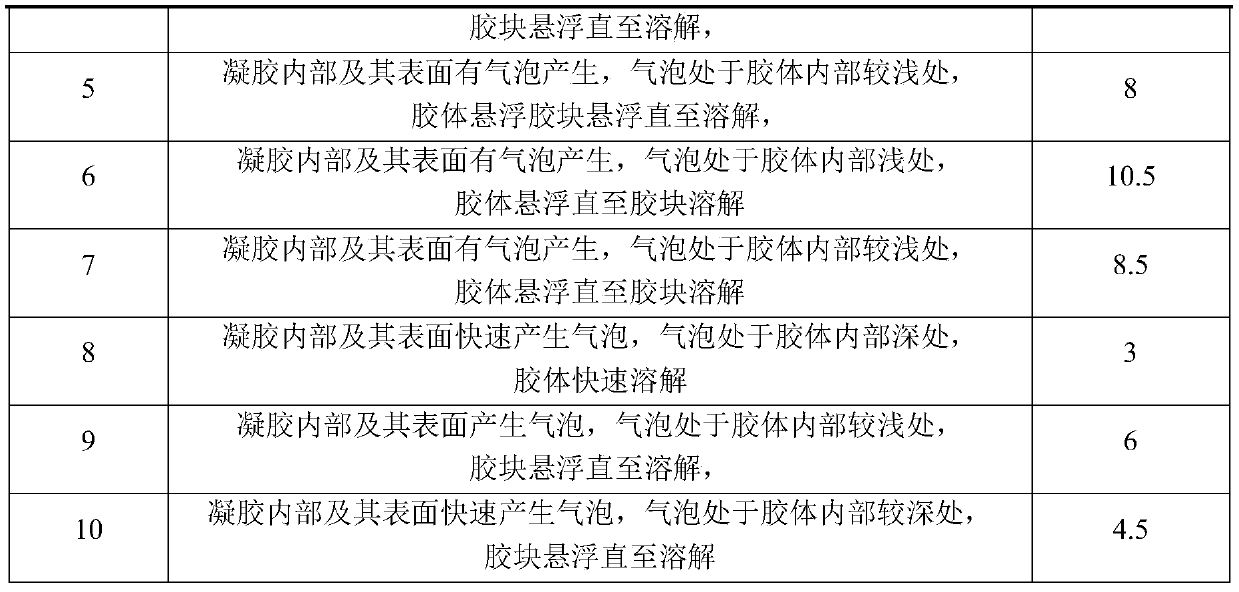

Examples

Embodiment 1

[0025] A polyacrylamide / chrome gel room temperature static breaker, comprising the following raw materials in mass percentage: 2% sodium hydroxide, 0.01% saturated cardanol polyoxyethylene ether (ethylene oxide n=5), 20% hydrogen peroxide, 0% polyether, and the balance is water; wherein the hydrogen peroxide is an aqueous hydrogen peroxide solution with a mass fraction of 27.5%.

[0026] The preparation method of the above-mentioned polyacrylamide / chromium gel room temperature static breaker comprises the following steps: adding water, alkaline substances, surfactants and polyether in proportion to the reactor in sequence, and when the solution is cooled to room temperature , add peroxide, and stir for 30min to 60min; in this embodiment, water, sodium hydroxide, and saturated cardanol polyoxyethylene ether are added in proportion to the reactor in sequence, and when the solution is cooled to room temperature, hydrogen peroxide is added, Stir for 30min to 60min.

[0027] The m...

Embodiment 2

[0029] A polyacrylamide / chrome gel room temperature static breaker, comprising the following raw materials in mass percentage: 1% sodium hydroxide, 0.05% saturated cardanol polyoxyethylene ether (ethylene oxide n=13), 20% Hydrogen peroxide, 10% polyol type polyether (glycerol ethylene oxide-propylene oxide block polyether), balance is water; Wherein said hydrogen peroxide is the hydrogen peroxide that mass fraction is 27.5% aqueous solution.

[0030] The above-mentioned polyacrylamide / chromium gel room temperature static breaker, except for the different components and contents, the preparation and use methods are the same as in Example 1.

Embodiment 3

[0032] A preparation method of polyacrylamide / chrome gel room temperature static breaker, comprising the following raw material composition in mass percentage: 0.75% sodium hydroxide, 12.5% saturated cardanol polyoxyethylene ether (ethylene oxide n=13) , 10% hydrogen peroxide, 5% ethylene oxide-propylene oxide block polyether, and the balance is water; wherein the hydrogen peroxide is an aqueous hydrogen peroxide solution with a mass fraction of 27.5%.

[0033] The above-mentioned polyacrylamide / chromium gel room temperature static breaker, except for the different components and contents, the preparation and use methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com