Acid diffusion inhibitor with ester bonds, preparation method thereof and photoresist composition

An acid diffusion and inhibitor technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of aminohydroxy compounds, etc., can solve the mismatch of mutual solubility of polymer compounds, brittle cracking of photoresist films, and poor film-forming ability and other problems, to achieve the effect of improving resolution and line width roughness, improving film forming ability, and improving distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

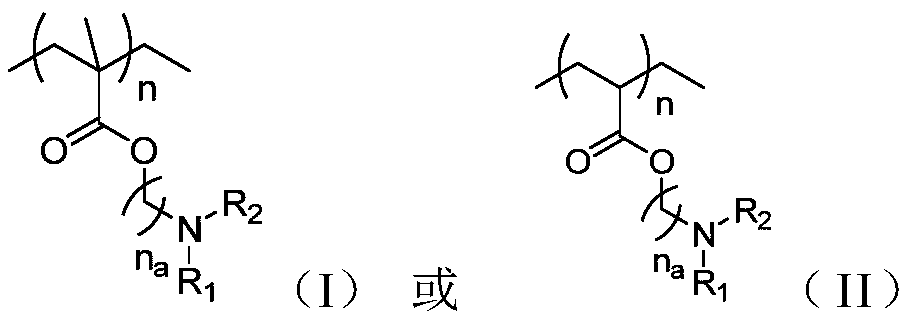

Method used

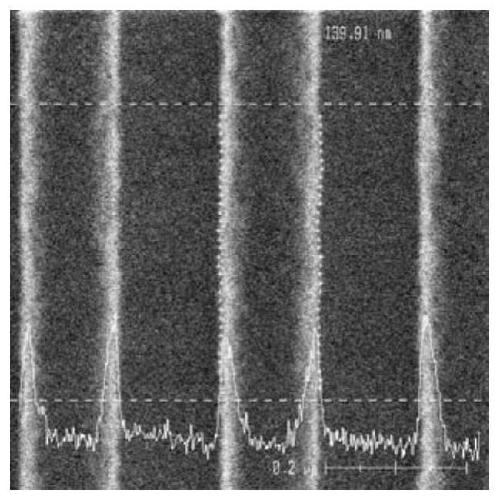

Image

Examples

preparation example Construction

[0068] The preparation method of the acid active film-forming resin is as follows: the comonomer is prepared by polymerizing in a solvent in the presence of a free radical initiator. In the polymerization reaction of acid active film-forming resin, initiator is the free radical initiator of azo initiator, peroxide, preferred azo initiator is azobisisobutyronitrile or azobisisoheptanonitrile, preferred The free radical initiator of peroxide is tert-butyl peroxypivalate, tert-butoxyhydroperoxide, benzoic acid hydroperoxide or benzoyl peroxide etc.; The amount of initiator is the total mass of comonomer 0.3% to 15% of the initiator; the way of adding the initiator is to add the monomer and part of the solvent first, then heat to the polymerization temperature, and then add the initiator solution dropwise. The temperature of the polymerization reaction is controlled between 40-90° C. according to the solvent and the initiator used, and the polymerization time is also controlled be...

Embodiment 1

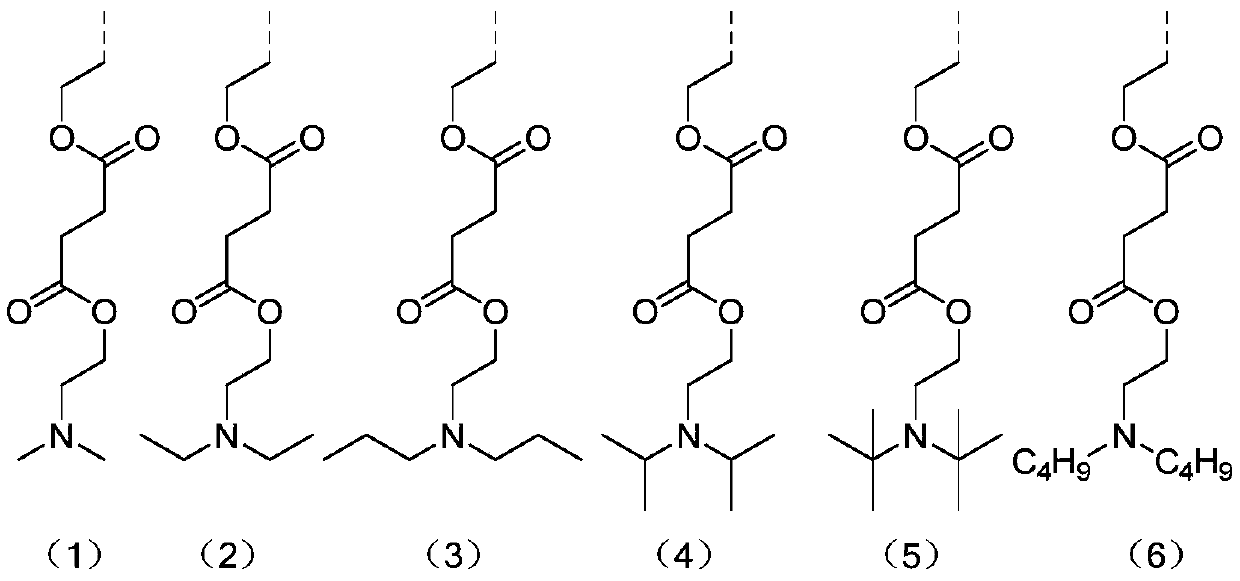

[0082] A preparation of (meth)acrylates with basic groups:

[0083]

[0084] The preparation method is as follows: In a round-bottomed flask equipped with cooling, add 20g of basic long-chain compounds containing ester bonds, 13g of triethylamine and 150g of dichloromethane, and cool the mixture to 0°C. Then, 11 g of (meth)acryloyl chloride was added dropwise with stirring, and a large amount of solids were precipitated. After adding, continue to stir for 2h. Then the reaction liquid was slowly raised to room temperature, washed twice with saturated aqueous sodium carbonate solution, 200 mL each time; then washed twice with 150 mL pure water; finally washed once with 150 mL saturated brine. The organic phase was dried over anhydrous sodium sulfate, concentrated, and distilled to obtain 25 g of N,N-dimethylethanol (meth)acrylate, with a yield of 82%. NMR results: 1 H NMR (CDCl 3 , δ) 2.11, s, 3H; 2.90, s, 6H; 2.63-2.75, m, 4H; 3.31, m, 2H; 4.30-4.41, m, 6H; 5.5, s, 1H; 6.5...

Embodiment 2

[0086] An acid diffusion inhibitor with an ester bond is prepared from the following comonomers under the condition of the presence of a free radical initiator by heating for copolymerization:

[0087]

[0088] The preparation method is as follows: add 50g of basic methacrylic acid monomer and 300g of methyl ethyl ketone into a 500mL four-necked bottle equipped with a heated electromagnetic stirrer, condenser, and thermometer, stir for 10 minutes under nitrogen, and then heat to 65-70 ℃. Then add 2.5g of azobisisobutyronitrile (AIBN) and 50g of methyl ethyl ketone solution dropwise to the reaction system within 10 minutes, continue to react and reflux for 8-12h after the addition, and then cool to room temperature to obtain a mixture; Precipitate in electronic grade n-hexane, filter with suction, take the filter residue, dissolve it with 200g electronic grade acetone, and then place it in electronic grade n-hexane to precipitate again, filter, take the filter residue, dry, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com