Genetically engineered bacterium for producing lipase by using methanol and xylose co-substrate and application of genetically engineered bacterium

A technology of genetically engineered bacteria and lipase, applied in the field of bioengineering, can solve the problem of high cost of producing lipase, and achieve the effect of reducing production cost, great significance and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

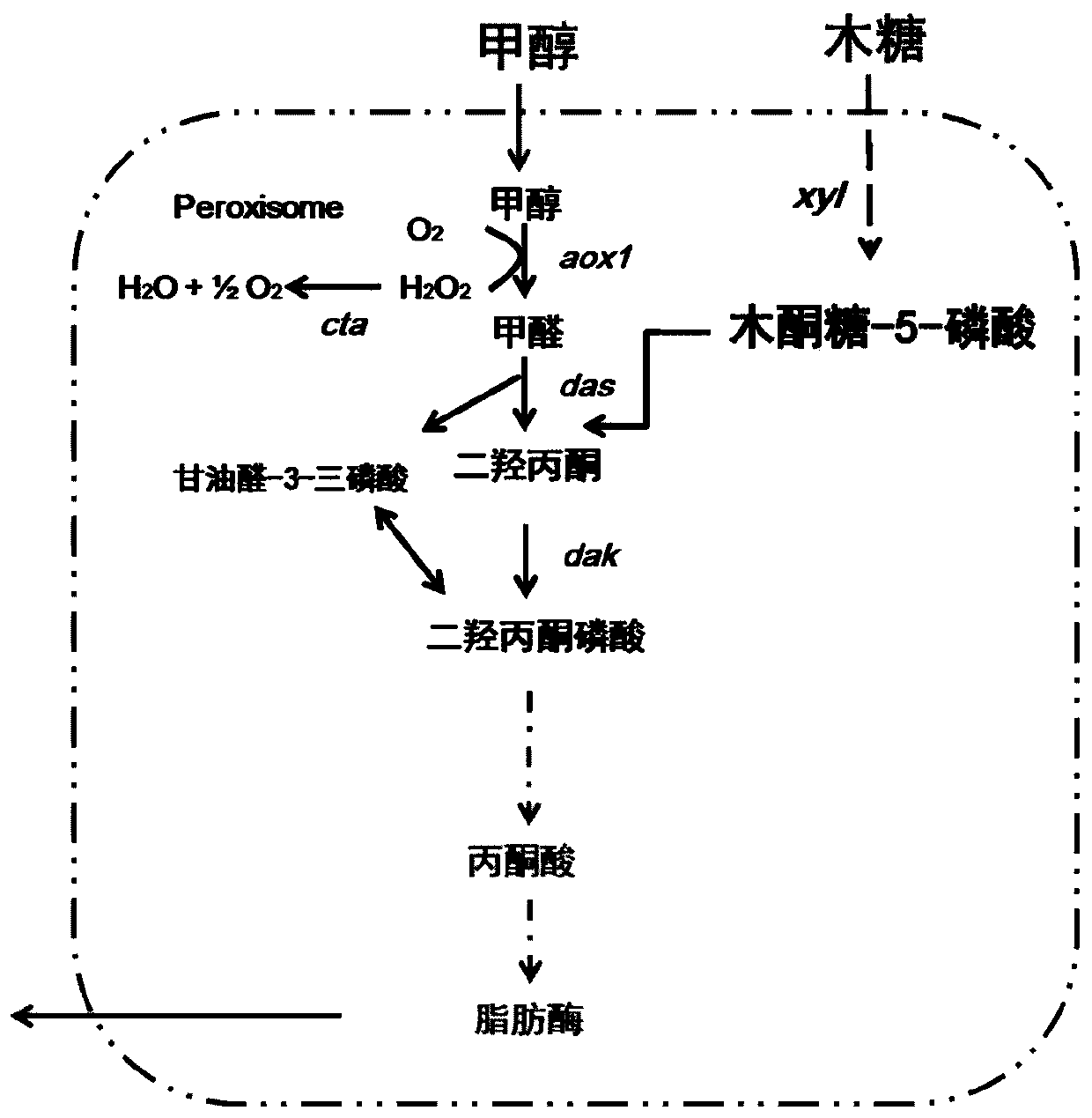

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Obtaining expressed genes

[0038] Pichia pastoris Pichia pastoris Using the genome as a template, design primers to amplify methanol oxidase aox 1. Dihydroxyacetone synthase gene das , catalase gene cta , dihydroxyacetone kinase gene dak .

Embodiment 2

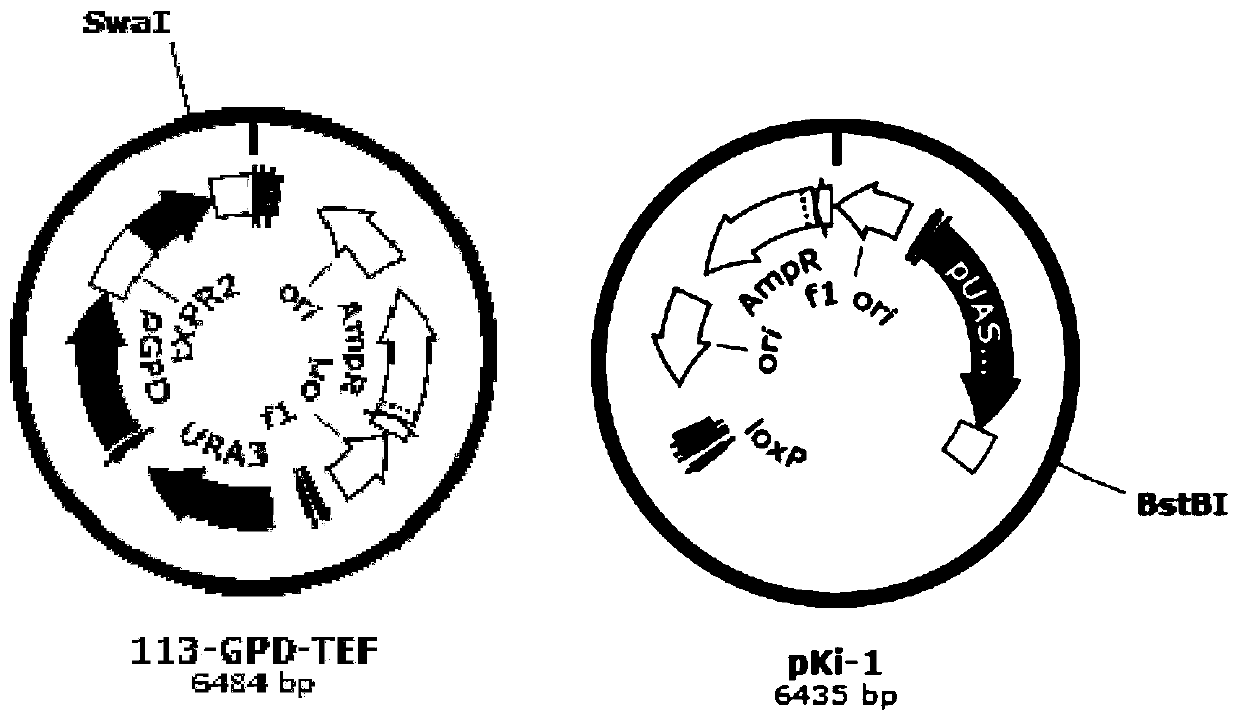

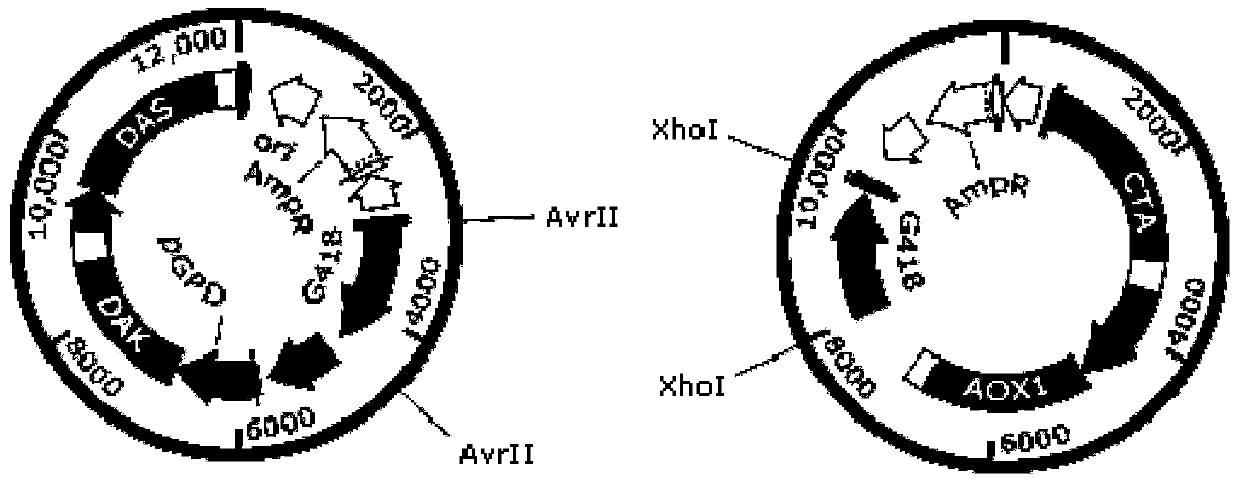

[0039] Embodiment 2: Utilize the method construction of synthetic biology Candida - aox 1- das - cta - dak

[0040] In order to quickly and effectively realize the co-expression of multiple genomes and ensure the stability of gene expression, the gene expression cassette was integrated into the Candida antarctica genome by using the method of DNA assembly.

[0041] (1) Design primers for amplification, add promoter and terminator homology arms at both ends of each gene, design upstream and downstream primers, and obtain expression cassettes. The gene and primer sequences are shown in Table 1.

[0042] Table 1 Gene and primer sequences

[0043]

[0044] (2) Perform multi-fragment cloning to form a promoter-gene-terminator expression cassette TEF- aox 1-CYC1t, TEF- das -tCYC1, PDC1p- cta -TDH2t, pGPD- dak - TXPR2; the expression cassette of the above-mentioned promoter-gene-terminator is to combine and connect the indicated genes to form an expression fragment b...

Embodiment 3

[0059] Embodiment 3: the fermentation experiment of recombinant bacterial strain

[0060] (1) Test tube seed culture: inoculate recombinant Candida antarctica at 1% (v / v) inoculation amount from the cryopreservation tube into the test tube seed medium, the liquid volume in the test tube is 5 mL, and cultivate aerobically at 24°C for 18-22 h, to obtain the test tube seed culture solution.

[0061] Wherein, the formula of the seed medium is as follows: peptone 6 g / L, hydrolyzed casein 4 g / L, yeast powder 3 g / L, beef extract 1.5 g / L, glucose 1 g / L.

[0062] (2) Shake flask seed culture: Inoculate the test tube seed culture solution from the test tube culture medium to the shake flask seed culture medium according to the inoculum amount of 1% (v / v). The liquid volume in a 250 mL Erlenmeyer flask is 50 mL, and cultivate aerobically at 24 °C After 18-22 hours, the shake flask seed culture solution was obtained.

[0063] (3) Production of lipase by fermentation: Inoculate the shake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com