Method for measuring molybdenum content in molybdenum waste residues

A determination method and waste residue technology, applied in the field of analytical chemistry, can solve the problems of not meeting the needs of rapid determination of molybdenum waste residues, the detection range cannot cover molybdenum waste residues, and the experience requirements of inspectors are high, so as to meet product quality supervision and inspection, promotion and application value. Great, reduce the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In the embodiment of the present invention, the inductively coupled plasma optical emission spectrometer is an Agilent 5110.

[0042] 1. Digestion and preparation of molybdenum waste residue samples

[0043] 1. Put the sample in an agate mortar and grind it by hand, pass through an 80-mesh sieve, take 10g-20g of the sieved sample according to the quartering method, put it in a 500ml glass beaker, and keep it in a drying oven at 110°C for 2 hours. Drying, place the dried sample in a desiccator to cool to room temperature;

[0044] 2. Configure anhydrous sodium carbonate and borax mixed solvent (according to the mass ratio of 2.5:1);

[0045] 3. Weigh 0.10 g of molybdenum waste slag cooled to room temperature in step 1, place it in a platinum crucible filled with 2.0 g of mixed flux in advance, and then cover with 1.5 g of mixed flux. Place the platinum crucible in a high-temperature furnace and heat it up to 920°C for 20 minutes. Take out and cool to room temperature....

Embodiment 2

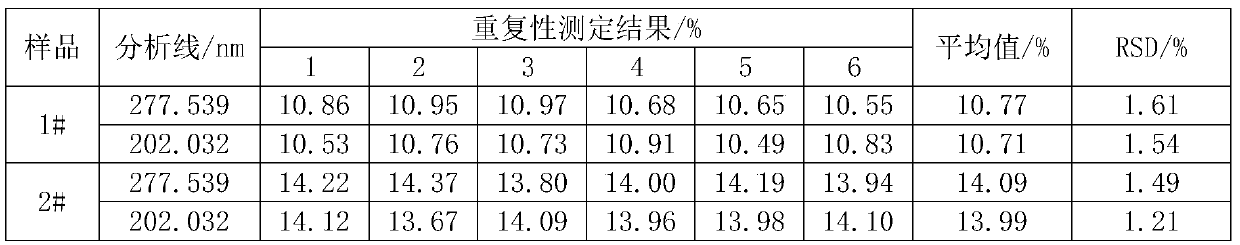

[0055] Embodiment 2 precision test

[0056] Two molybdenum waste slag samples were respectively prepared and analyzed for 6 independent detection sample solutions, and the results of the 6 measurements were statistically processed, and the precision of the present invention was evaluated according to the relative standard deviation (RSD%). The measurement results are shown in Table 2.

[0057] Table 2: Analytical method precision (n=6)

[0058]

[0059] It can be seen from Table 2 that the RSD (relative standard deviation) is not more than 2.0%, indicating that the present invention has good precision. It can be seen in Table 2 that the determination results of the two analytical lines of molybdenum element for the same sample are basically the same.

Embodiment 3

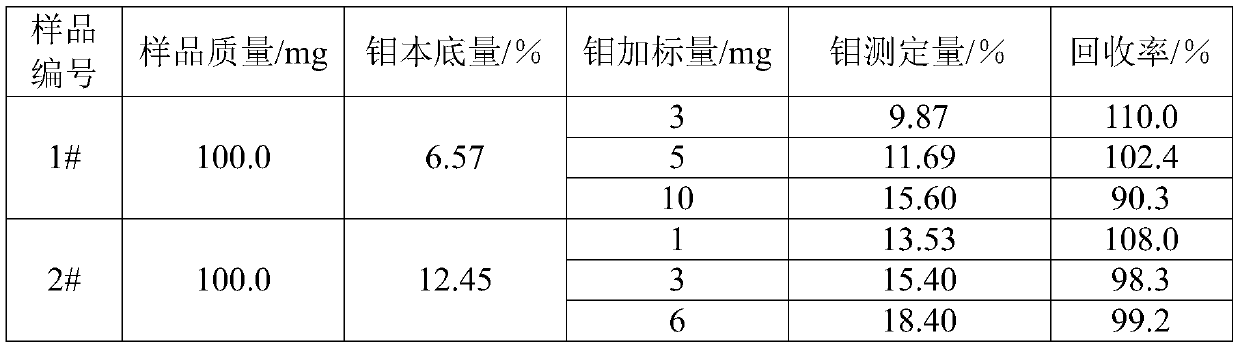

[0060] The recovery rate of standard addition of embodiment 3 method The recovery rate is the important index of characterizing the accuracy of the method, in two molybdenum content known molybdenum waste residue samples (content is respectively 6.57% and 12.45%), add the molybdenum standard solution of different content to carry out Spike recovery test. According to the experimental method, three parts of 0.10 g of a molybdenum waste slag sample were weighed for high-temperature melting, and three kinds of molybdenum standard solutions (1 mg / mL) with different content gradients were added before constant volume. During instrumental analysis, input the sample mass on the software, measure the molybdenum content of the spiked mixture, and calculate the spiked recovery rate. The test results are listed in Table 3.

[0061] Table 3: Spike recoveries for methods

[0062]

[0063] As can be seen from Table 3, the recovery rate of the method established by the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com