Biosynthesis method of FeS-coated rGO composite material

A technology for biosynthesis and composite materials, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of harsh reaction conditions, environmental pollution, high energy consumption of chemical synthesis methods, and achieve high selectivity, Easy to operate and easy to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

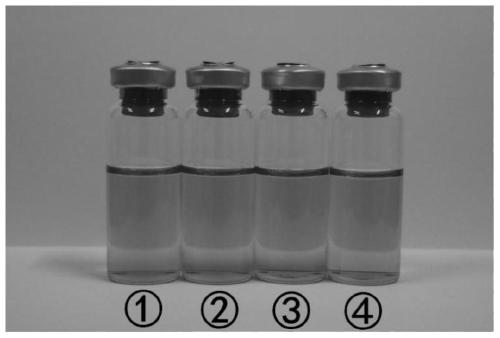

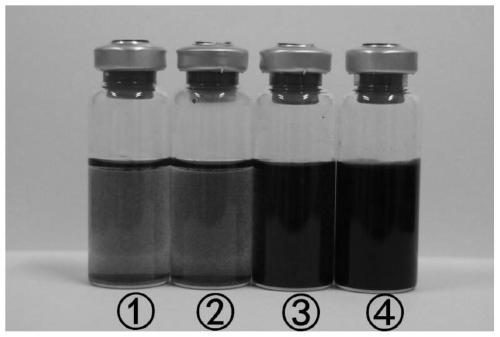

[0031] (1) Cultivation of Shewanella: select strain Oneida Shewanella ( Shewanella oneidensis MR-1), purchased from ATCC American Type Culture Collection, strain number ATCC700550; add 200 mL of LB medium (containing yeast extract 5 g / L, tryptone 10 g / L and sodium chloride 5 g / L L, pH=7) was inserted into Shewanella species, cultured at a temperature of 30 °C and a shaking speed of 200 rpm for 12 h to obtain a bacterial liquid;

[0032] (2) Construction of the buffer system: its specific components include Na 2 HPO 4 12H 2 O 17.8 g / L, KH 2 PO 4 3 g / L, NaCl 0.5 g / L, NH 4 Cl 0.5g / L, 18 mM sodium lactate, CaCl 2 0.1 mM, MgSO 4 1 mM, GO 50 mg / L;

[0033] (3) GO is converted into rGO; the cultured Shewanella is taken out, and the concentration is controlled at OD according to the concentration conversion 600=0.5, centrifuge the bacteria sludge and disperse it into the mixed system in step (2). The conditions of constant temperature shaking culture are controlled at a t...

Embodiment 2

[0046] It is basically the same as in Example 1, only the final concentration of the added ferric chloride and sodium thiosulfate is controlled to 1 mM, and the FeS@rGO composite material is obtained, which is marked as ②; XRD is carried out on the FeS@rGO prepared in this example characterization.

Embodiment 3

[0048] It is basically the same as in Example 1, only the final concentration of the added ferric chloride and sodium thiosulfate is controlled to 5 mM, and the FeS@rGO composite material is obtained, which is marked as ③; XRD is carried out on the FeS@rGO prepared in this example characterization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com