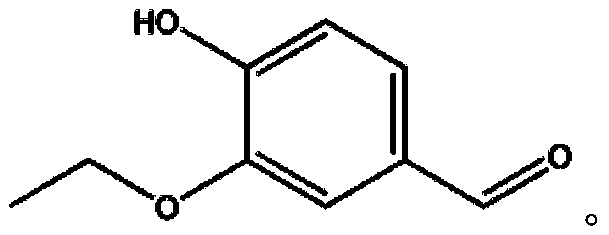

Method for preparing ethyl vanillin from sassafras oil

A technology of ethyl vanillin and sassafras oil, which is applied in the field of preparing ethyl vanillin from sassafras oil, can solve the problems of difficult product purification, urgent improvement of yield, and long reaction cycle, and achieves mild process conditions and improved Utilization rate, the effect of less usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 sassafras oil prepares ethyl vanillin

[0031] 1. Raw materials: sassafras oil, KOH, methanol, diethyl sulfate, ethanol, sulfuric acid, acetic anhydride, sodium carbonate, ozone, sodium pyrosulfite, liquid caustic soda, concentrated hydrochloric acid

[0032] 2. Preparation process:

[0033] (1) Put 100g of sassafras oil, 100g of methanol, and 100g of potassium hydroxide into the reaction flask, raise the temperature to 130°C for 1 hour, then distill methanol under normal pressure, and raise the temperature while steaming methanol until the temperature reaches 150- Between 160°C, the duration is about 6h. Wait until the content of safrole <1%, that is judged as the end of the reaction, stop heating. When the reaction solution is cooled to 90°C, slowly add 200g of water and mix well. Then the reaction solution was poured into a separatory funnel, allowed to stand for phase separation, and the lower alkali aqueous phase was separated, and 320 g of the uppe...

Embodiment 2

[0039] The preparation of embodiment 2 ethyl vanillin

[0040] 1. Raw materials: sassafras oil, KOH, methanol, diethyl sulfate, ethanol, sulfuric acid, acetic anhydride, sodium carbonate, ozone, sodium pyrosulfite, liquid caustic soda, concentrated hydrochloric acid

[0041] 2. Preparation process:

[0042] (1) Put 500g of sassafras oil, 400g of methanol, and 400g of potassium hydroxide into a reaction flask, raise the temperature to 120-140°C for 1 hour, then distill out methanol under normal pressure, and raise the temperature while distilling methanol until the temperature reaches Between 150-160°C, the duration is about 6h. Wait until the content of safrole <1%, that is judged as the end of the reaction, stop heating. When the reaction liquid is cooled to 90°C, slowly add 800g of water and mix well. Then the reaction solution is poured into a separatory funnel, left to separate phases, the lower alkali aqueous phase is separated, and 1500 g of the upper layer potassium ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com