Force-induced responsive hybrid cross-linked dynamic polymer

A technology of hybrid cross-linking and polymers, applied in the field of Lizhi responsive hybrid cross-linking dynamic polymers, which can solve the problems of difficult to meet the needs of material development, difficult to reflect responsiveness and dynamics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

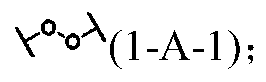

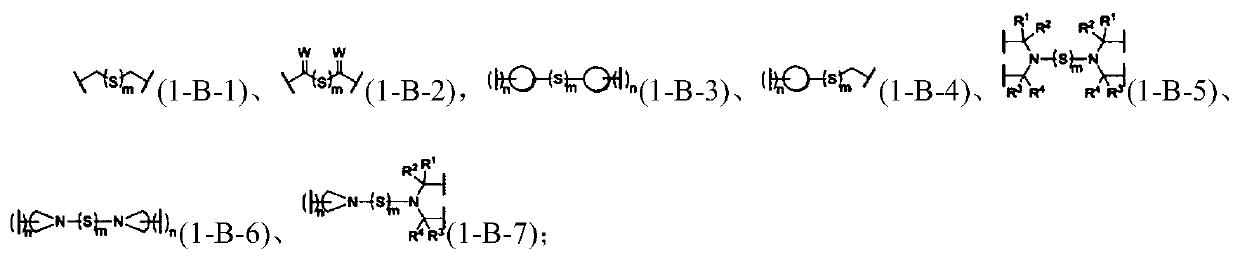

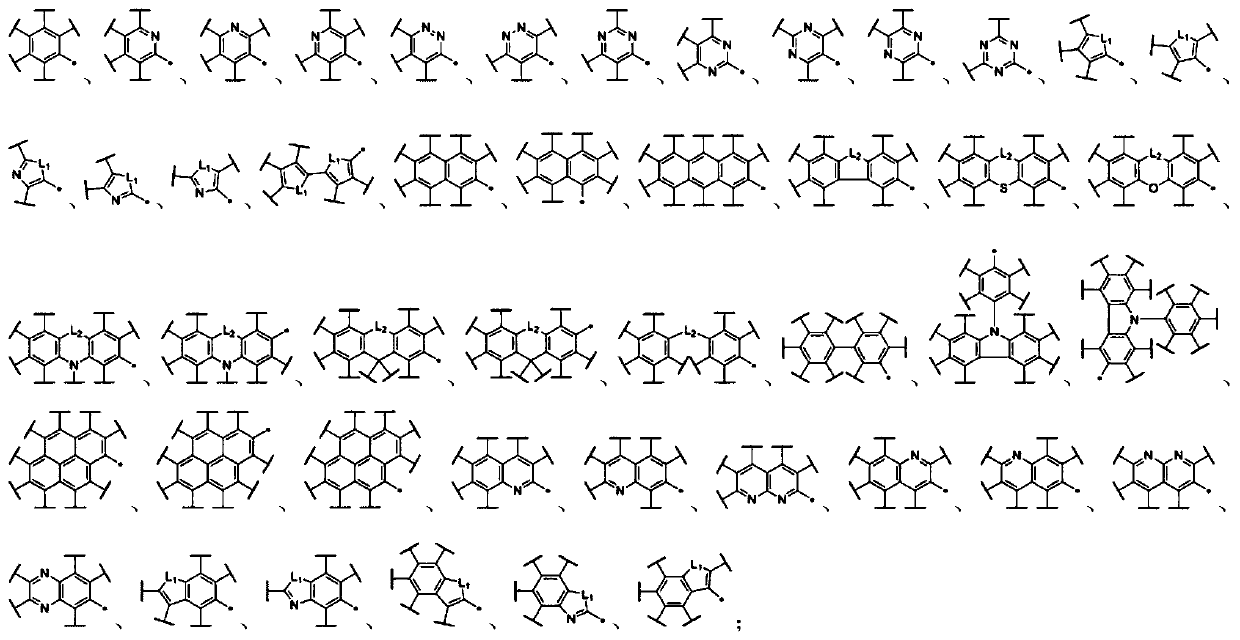

Method used

Image

Examples

Embodiment approach

[2104] In the present invention, the dynamic polymer may have one, two or more than two glass transition temperatures, or may not have a glass transition temperature. Among them, in a preferred embodiment of the present invention, at least one of the glass transition temperatures of the dynamic polymer is higher than 100°C, more preferably all of them are higher than 100°C, the dimensional stability, mechanical strength, Good high temperature resistance, suitable for energy absorption scenarios with high requirements for stress bearing and rigidity; in another preferred embodiment of the present invention, at least one of the glass transition temperatures of the dynamic polymer is between 25°C and 100°C between 25°C and 100°C, more preferably between 25°C and 100°C, which facilitates the preparation of polymer products in the form of ordinary solids, foams, and gels above room temperature, and is suitable for energy-absorbing situations that require high mechanical strength and...

Embodiment 1

[2142]

[2143] Using dicumyl peroxide as an initiator, graft-modified low-molecular-weight polyethylene with maleic anhydride through melt grafting reaction to obtain graft-modified polyethylene, wherein the mass of dicumyl peroxide and maleic anhydride The ratio is 1:10; then, using p-toluenesulfonic acid as a catalyst, 1-aminoethylboronic acid is used to prepare boric acid graft modified polymer (b) through melt grafting reaction. Get 50g boric acid graft modified polyethylene (b), 15g ethylene-vinyl alcohol copolymer, 9g dioctyl phthalate, 15g compound (a), 6.2g stearic acid, 5.4g tribasic basic sulfuric acid Lead, 1.6g of di-n-butyltin dilaurate, and 1.2g of dimethyl silicone oil are mixed evenly, then added to a small internal mixer and kneaded for 10 minutes, then added 10g of carbon fiber and continued to knead. After completion, the kneaded material was taken out and cooled. , placed in a twin-roller machine at 150°C, pressed into thin sheets, cooled at room temper...

Embodiment 2

[2145]

[2146] Dissolve 15.2g of 2-(aminomethyl)phenylboronic acid and 15.4g of 4-amino-1,3-benzenedimethanol in 300mL deionized water / THF mixed solvent, heat to 50°C for 2h stirring and dissolving reaction, remove solvent to obtain 27.3 g of compound (b). An isocyanate-terminated prepolymer was prepared by reacting 25 g of MDI with 100 g of polyether polyol. Mix and dissolve 1 molar equivalent of compound (a) and 1 molar equivalent of compound (b) in toluene, add 0.01 molar equivalent of triethylamine, stir and heat to 80°C, slowly add 2 molar equivalents of isocyanate-terminated prepolymer, and then The reaction was continued for 2 h, and then methanol was added for capping. After the reaction was complete, the solvent was removed to obtain product 1. 1 molar equivalent of hydrogen-containing silicone oil (average molecular weight is about 20000, the molar ratio of repeating units containing silicon hydrogen to repeating units not containing silicon hydrogen is about 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com