Preparation of porous hetero-element modified two-dimensional carbon material and application of porous hetero-element modified two-dimensional carbon material in chloroethylene synthesis reaction

A technology of two-dimensional carbon materials and heteroelements, which is applied in the direction of hydrogen halide addition preparation, catalyst activation/preparation, chemical instruments and methods, etc., to achieve the effects of low production cost, high specific surface area, and rich pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

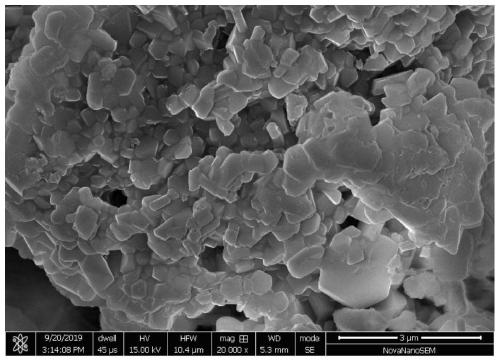

[0048] 1) Add 24.6g of 1-butyl-3-methylimidazolium tetraphenyl borate to 20g of graphene, microwave digestion frequency 300MHz, processing time 1h, so that heterogeneous elements are evenly distributed on the surface of graphene;

[0049] 2) Pass the above mixture into diborane for gas pre-adsorption for 2 hours at a temperature of 200°C;

[0050] 3) Put the above mixture in a plasma furnace with a nitrogen atmosphere, apply an electric field of 100V / m, and use the ions generated by the ionization of the working gas to further etch the defect and modify the material for 1 hour.

[0051] 4) washing the above-mentioned material with deionized water, and drying at 80° C. for 4 hours to obtain the porous heteroelement-doped porous two-dimensional graphene material;

[0052] 5) Evaluation of acetylene hydrochlorination reaction on a fixed bed reactor device: the effects of temperature and space velocity on the catalytic performance of the catalyst were investigated respectively, an...

Embodiment 2

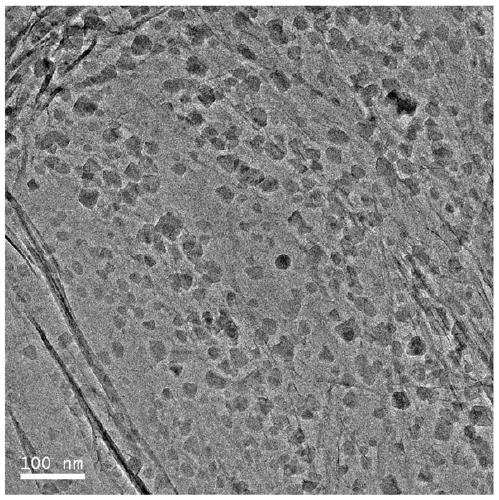

[0054] 1) Add 17.5g of N-ethylpyridine dinitrile amine salt to 16g of graphene, microwave digestion frequency 800MHz, processing time 2h, so that heterogeneous elements are evenly distributed on the surface of graphene;

[0055] 2) Pass the above mixture into ammonia gas for gas pre-adsorption for 3 hours at a temperature of 300°C;

[0056] 3) Put the above mixture in a plasma furnace with a nitrogen atmosphere, apply an electric field of 500V / m, and use the ions produced by the ionization of the working gas to further etch the defect and modify the material for 1.5 hours.

[0057] 4) washing the above material with deionized water, and drying at 90° C. for 8 hours to obtain the porous heteroelement-doped porous two-dimensional graphene material;

[0058] 5) Evaluation of acetylene hydrochlorination reaction on a fixed bed reactor device: acetylene hydrochlorination reaction at 180°C, acetylene space velocity 40h -1 , under the condition of hydrogen chloride: acetylene = 1:1,...

Embodiment 3

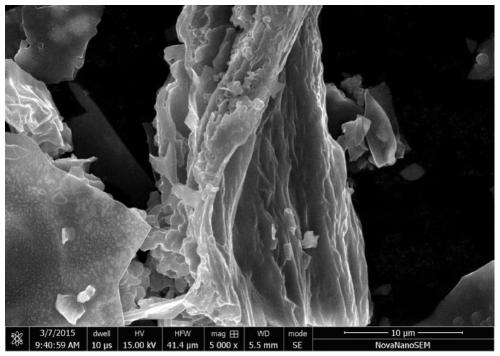

[0060] 1) Add 15.2g N-picoline thiocyanate to 12g graphene alkyne, microwave digestion frequency 1200MHz, processing time 3h, make heterogeneous element evenly distribute on the graphene surface;

[0061] 2) Pass the above mixture into hydrogen sulfide for gas pre-adsorption for 4 hours at a temperature of 500°C;

[0062] 3) Put the above mixture in a plasma furnace with a nitrogen atmosphere, apply an electric field of 700V / m, and use the ions generated by the ionization of the working gas to further etch the defect and modify the material for 2 hours.

[0063] 4) washing the above material with deionized water, and drying at 120° C. for 12 hours to obtain the porous heteroelement-doped porous two-dimensional graphene material;

[0064] 5) Evaluation of acetylene hydrochlorination reaction on a fixed bed reactor device: acetylene hydrochlorination reaction at 180°C, acetylene space velocity 40h -1 , hydrogen chloride: acetylene = 1:1.1 conditions. The reaction conversion ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com