Flexible graphene heating film and preparation method thereof

An ene heating film and flexible graphite technology, applied in the field of nanomaterials, can solve the problems of difficult to guarantee heating uniformity, poor high-voltage breakdown force, service life discount, etc., to achieve excellent electronic conduction performance, stable heating resistance, and extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

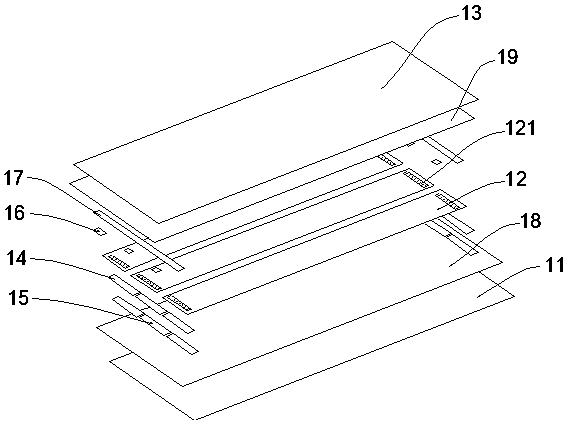

[0076] The preparation method of flexible graphene heating film of the present invention comprises the following steps:

[0077] Step 1: Provide a carrier and print graphene slurry on both ends of the carrier, continue to lay electrode strips on the graphene slurry, and after the graphene slurry solidifies, prepare the carrier and the graphene strips and electrodes connected to the carrier strip.

[0078] The second step: arrange palladium quantum dots doped graphene-based conductive ink on the carrier with graphene strips and electrode strips by scraping, spin coating, direct writing, screen printing or inkjet printing, and obtain graphene heating after curing coating;

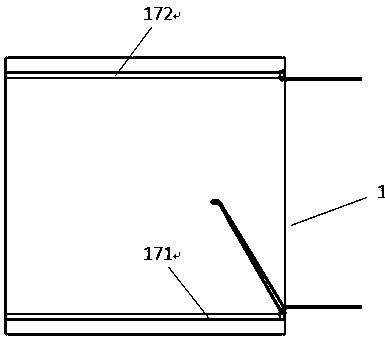

[0079] The third step: the electrode connecting section and the electrode current-carrying bar are arranged at the two ends of the above-mentioned graphene heating coating, wherein, an electrode connecting section is respectively provided at the two ends of any graphene heating coating, in other embodiments,...

Embodiment 1

[0083] Preparation of graphene oxide acetone dispersion: 500 mg of graphite powder was provided, and graphene oxide (Graphene Oxide, GO) was prepared by a modified Hummers method. In order to further obtain few-layer graphene oxide, place graphene oxide in an ice-water bath, use an ultrasonic disperser to sonicate for 10 minutes at a power of 250W, repeat once, take the supernatant, centrifuge, and resuspend in acetone to obtain a thickness ranging from 12 to Graphene oxide acetone dispersion liquid with 20 layers and lateral dimension of 700-1000nm. Concentrate by centrifugation as required to adjust the concentration of the graphene oxide acetone dispersion to 150 mg / ml.

[0084] Preparation of palladium quantum dot-doped graphene dispersion: take 50ml of the graphene oxide acetone dispersion prepared above and add 0.05g of phosphomolybdic acid to it, stir at 600rpm for 10h, centrifuge at 15000rpm for 30min, and collect the first precipitate at the bottom of the centrifuge t...

Embodiment 2

[0090] Preparation of graphene oxide acetone dispersion: 500 mg of graphite powder was provided, and graphene oxide (Graphene Oxide, GO) was prepared by a modified Hummers method. The prepared graphene oxide was further transferred to a high-temperature carbonization furnace for high-temperature carbonization for 30 s. The high-temperature carbonization furnace was filled with nitrogen gas, and the temperature of the high-temperature carbonization furnace was 1200° C. In order to further obtain few-layer graphene oxide, place the graphene oxide expanded at high temperature in an ice-water bath, use an ultrasonic disperser to sonicate for 20 minutes at a power of 250W, repeat once, take the supernatant, centrifuge, and resuspend in acetone. A graphene oxide acetone dispersion liquid with a thickness ranging from 8 to 15 layers and a lateral dimension of 700 to 1000 nm. Concentrate by centrifugation as required to adjust the concentration of the graphene oxide acetone dispersion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com