Preparation method of slow-release carbon source hollow rod

A technology of carbon source hollowing and hollowing rods, which is applied in chemical instruments and methods, special compound water treatment, water/sludge/sewage treatment, etc., and can solve problems such as different denitrification speeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

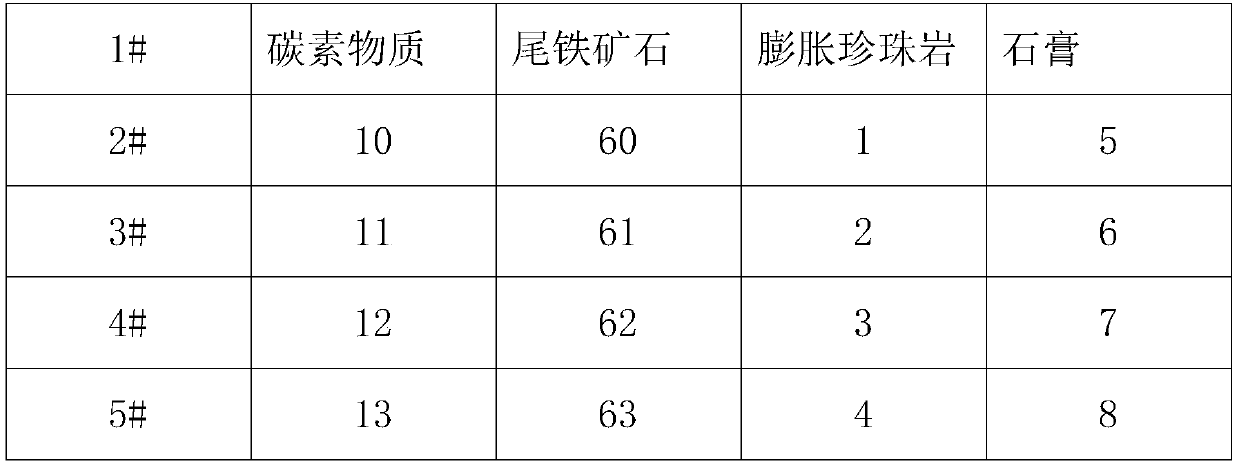

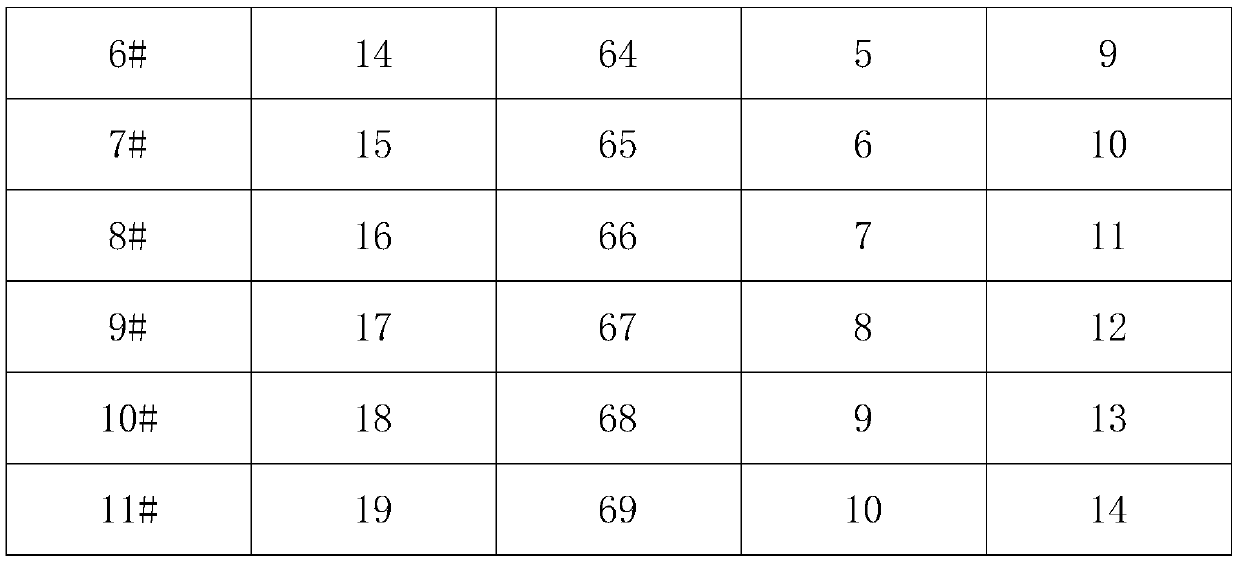

[0029] S1: Take the carbonaceous material that is 10-20 parts by mass, the tail iron ore that is 60-70 parts by mass, the expanded perlite that is 1-10 parts by mass and 5-15 parts by mass Parts of gypsum are ground to a particle size of less than 10 cm and mixed evenly;

[0030] S2: Heating the mixture in step S1 to 110-130° C. in a vacuum state, drying for 1.5-3 hours; then rapidly raising the temperature to 850-1000° C., and roasting for 3-5 hours;

[0031] S3: cooling the mixture in step S2 to 85-95°C and adding 1-5 parts by mass of K 2 O and 0.0009-0.01 part of Ce are stirred evenly, and are finely ground by the inner side of the ball mill. At this temperature, the purity of the mixture in step S1 can be guaranteed to be higher after the reaction, and the oxidation of the iron element can also be avoided when the temperature is too high. Compared with cooling to room temperature Reduced cooling water consumption.

[0032] S4: Add binder to the mixture after step S3 grin...

Embodiment 2

[0050] In step S2, the mixture in step S1 is heated to 115-130°C under vacuum, dried for 1.5-2.5 hours, then rapidly heated to 900-1000°C, roasted for 3.5-4.5 hours, and taken out of the high-temperature heating equipment by a vacuum pump To avoid the rapid combustion reaction of oxygen in the subsequent air with carbon, resulting in a large loss of carbon and ablation.

Embodiment 3

[0052] In step S2, the mixture in step S1 is heated to 115-120° C. under vacuum, dried for 1.5-2 hours, then rapidly heated to 900-950° C., and calcined for 3.5-4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com