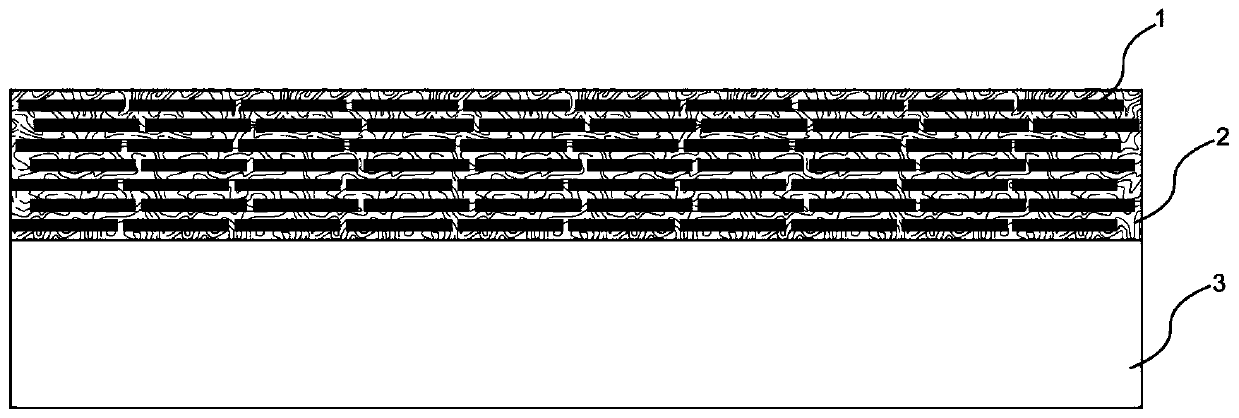

High-barrier polyimide composite film with shell-like dense structure and preparation method and application thereof

A technology of polyimide film and polyimide, which is applied in semiconductor/solid-state device manufacturing, coating, electrical components, etc., can solve the problems of not meeting OLED packaging requirements, and achieve improved gas barrier performance and good barrier performance , excellent barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

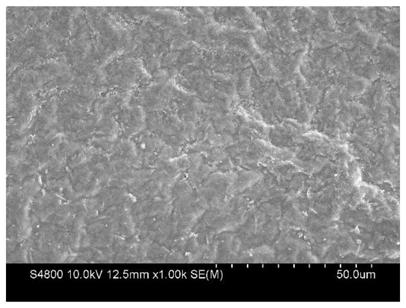

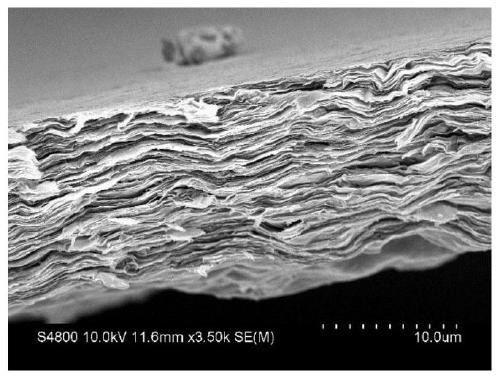

[0038] This example is a preparation example of a high-barrier polyimide composite film imitating a shell-like layered dense structure, and the high-barrier polyimide composite material imitating a shell-like layered dense structure is prepared according to the following steps:

[0039] (1) Preparation of nano-montmorillonite colloid: take 6g of sodium-based montmorillonite and 500mL of ultrapure water in a 1000mL single-mouth bottle, stir it with a mechanical stirrer at 800rpm for 24 hours, and separate the suspension obtained by a high-speed centrifuge The montmorillonite that has not been peeled off into a single layer is taken out (the set speed of the centrifuge is 9000rpm, and the centrifugation time is 6min), the supernatant is collected in a 500mL eggplant-shaped bottle, and part of the water is evaporated by rotary evaporation, and finally the concentration Be the montmorillonite colloid of 3.3% (mass fraction);

[0040] (2) Preparation of polyamic acid solution: Take...

Embodiment 2

[0046] This example is a preparation example of a high-barrier polyimide composite film imitating a shell-like layered dense structure, and the high-barrier polyimide composite material imitating a shell-like layered dense structure is prepared according to the following steps:

[0047] (1) Preparation of nano-montmorillonite colloid: Take 6g of sodium-based montmorillonite and 500mL of ultrapure water in a 1000mL one-mouth bottle, and use high-power ultrasound (900W) to continue ultrasonication for 50min. The resulting suspension was separated by a high-speed centrifuge to separate the montmorillonite that was not peeled off into a single layer (the set speed of the centrifuge was 9000rpm, and the centrifugation time was 6min). Part of the water is evaporated to finally obtain the montmorillonite colloid with a concentration of about 3.3% (mass fraction);

[0048] (2) Preparation of polyamic acid solution: Take 1.9044g (9.5112mmol) of ODA and 35mL of N,N'-dimethylformamide DM...

Embodiment 3

[0054] This example is a preparation example of a high-barrier polyimide composite film imitating a shell-like layered dense structure, and the high-barrier polyimide composite material imitating a shell-like layered dense structure is prepared according to the following steps:

[0055] (1) Preparation of nano-montmorillonite colloid: Take 6g of sodium-based montmorillonite and 500mL of ultrapure water in a 1000mL one-mouth bottle, and use high-power ultrasound (900W) to continue ultrasonication for 50min. The resulting suspension was separated by a high-speed centrifuge to separate the montmorillonite that was not peeled off into a single layer (the set speed of the centrifuge was 9000rpm, and the centrifugation time was 6min). Part of the water is evaporated to finally obtain the montmorillonite colloid with a concentration of about 3.3% (mass fraction);

[0056] (2) Preparation of polyamic acid solution: Take 1.9044g (9.5112mmol) of ODA and 35mL of N,N'-dimethylformamide DM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com