Sunscreen composition and application thereof

A technology of composition and extract, which is applied in the field of daily chemical products, can solve the problems of coenzyme Q10 instability, poor skin nourishing effect, and unutilized cistanche, and achieve the effect of reducing types and dosage, broad application prospects, and significant sunscreen effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1: sunscreen composition of the present invention

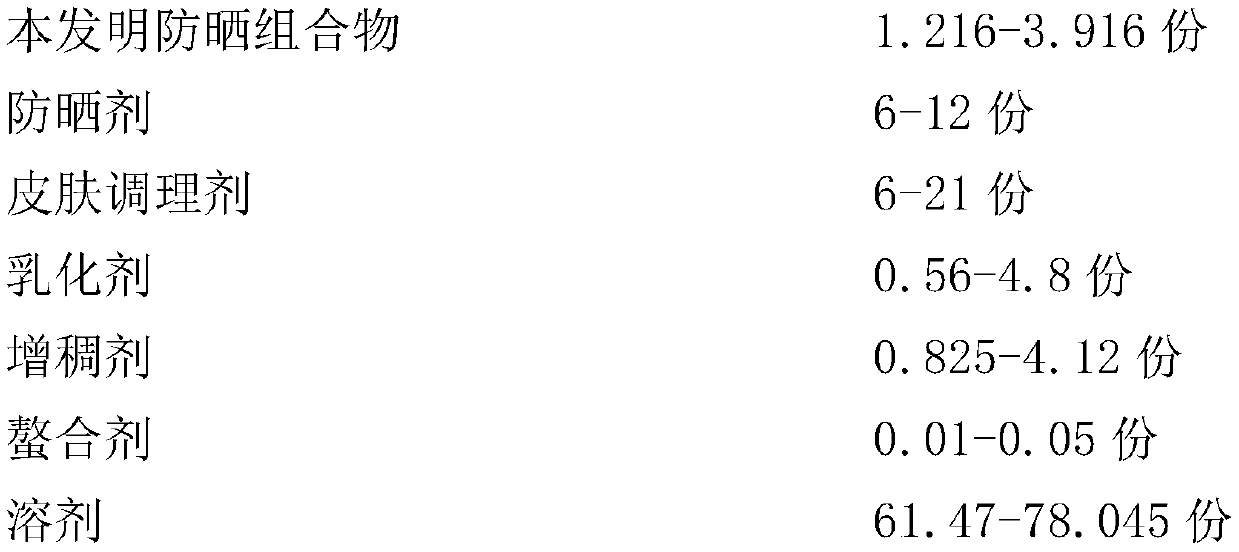

[0066] 1. Formula

[0067] Table 2

[0068]

[0069] 2. Comparative example

Embodiment 2

[0074] Embodiment 2: Contrastive test of sunscreen and whitening, moisturizing and anti-wrinkle effects

[0075] 1. Sunscreen effect test

[0076] Prepare blank emulsion, including oil phase: 3 parts of cetearyl alcohol, 2 parts of glyceryl stearate, 6.5 parts of white oil, 0.1 part of propylparaben; water phase: 0.1 part of xanthan gum, potassium lauryl phosphate 1.5 parts, 5 parts of glycerin, 0.15 parts of methylparaben, and 81.65 parts of water.

[0077] Select formula 1-5 in Example 1, control sample is comparative example 1-3, take 98 parts of blank emulsion, add 2 parts of test composition respectively. According to the "Safety and Technical Specifications for Cosmetics" (2015 Edition) Sunscreen Cosmetics SPF Test Method (Human Method) to test the sunscreen effect of the product, the test method is as follows:

[0078] Sun protection factor (SPF): Also known as the sun protection factor, it indicates the level of sun protection that sun protection products can exert. ...

Embodiment 3

[0092] Embodiment 3: Preparation of daily chemical product sunscreen

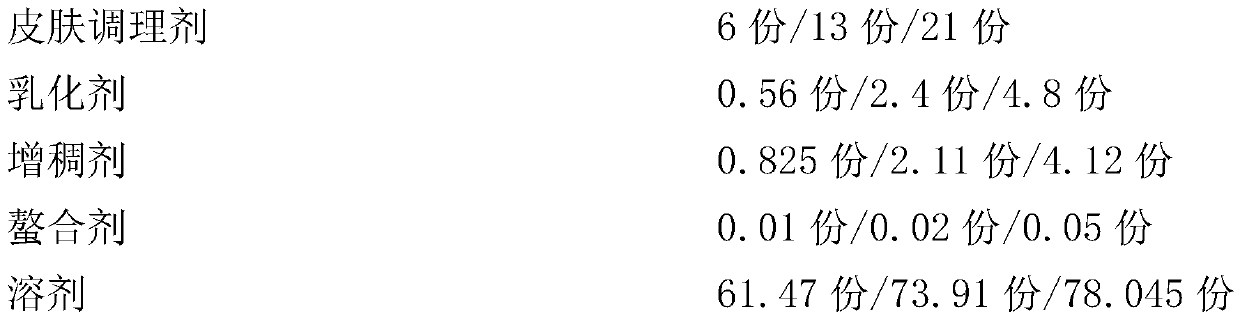

[0093] 1. Formula

[0094] table 5

[0095]

[0096] 2. Preparation method (if the formula does not contain a certain ingredient, the ingredient will not be added during the preparation process)

[0097] Step 1. Titanium dioxide, ethylhexyl methoxycinnamate, zinc oxide, ethylhexyl salicylate, C12-15 alcohol benzoate, caprylic / capric triglyceride, aluminum stearate, Mix and stir polyhydroxystearic acid, stearic acid, and aluminum oxide until transparent, and heat to 88°C to form an oil phase;

[0098] Water, butylene glycol, 1,2-hexanediol, 1,2-pentanediol, sodium stearyl glutamate, silica, polyester-5, polyacrylate crosspolymer-6, hydroxypropyl Add methylcellulose stearyl ether, ammonium acryloyldimethyl taurate / VP copolymer, and disodium EDTA into an emulsifier, stir and mix evenly, and heat to 88°C to form a water phase;

[0099] Step 2. Pump the oil phase into the water phase for homogeneous emuls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com