Preparation method of large-size lath-shaped artificial ruby crystal

A lath-shaped ruby technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of slow ruby crystal speed, poor uniformity, and high growth cost, and achieve the suppression of Cr3+ ion volatilization , Crystal physical properties are excellent, the effect of improving crystal utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

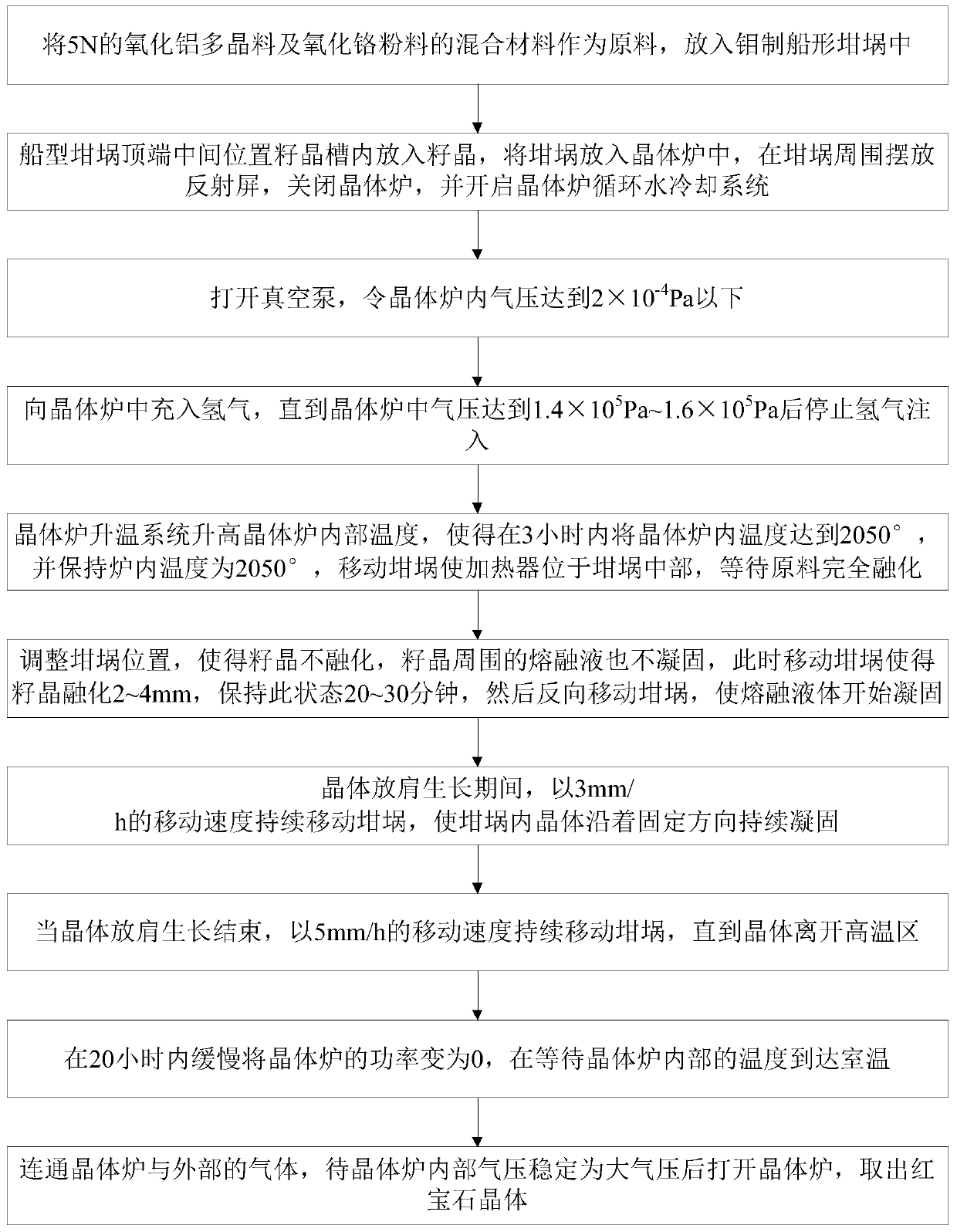

[0031] The invention provides a method for preparing a large-size lath-shaped artificial ruby crystal, comprising the following steps:

[0032] A: The mixed material of 5N alumina polycrystalline material and chromium oxide powder is used as a raw material and put into a molybdenum boat-shaped crucible;

[0033] B: Put the seed crystal in the seed crystal tank at the middle position on the top of the boat-shaped crucible, put the crucible into the crystal furnace, place a reflective screen around the crucible, close the crystal furnace, and turn on the circulating water cooling system of the crystal furnace;

[0034] C: Turn on the vacuum pump to make the air pressure in the crystal furnace reach 2×10 -4 Below Pa;

[0035] D: Fill hydrogen into the crystal furnace until the air pressure in the crystal furnace reaches 1.4×10 5 Pa~1.6×10 5 Stop hydrogen injection after Pa;

[0036] E: The crystal furnace heating system increases the internal temperature of the crystal furn...

Embodiment 1

[0048] In this example, a piece of ruby crystal with a size of 200×95×32 mm and a color of darker red pigeon’s blood red was prepared, and the preparation method included:

[0049] Select 2156.00g of 5N polycrystalline alumina and 44.00g of 5N chromium oxide powder, and put them into a boat-shaped molybdenum crucible with a size of 200×100×40mm;

[0050] Put the crucible containing the raw materials into the horizontal directional crystal growth furnace, place a heat shield around it, close the crystal furnace, turn on the circulating water, and evacuate to 2×10 -4 Pa, close the vacuum;

[0051] Fill in hydrogen to make the pressure in the crystal furnace reach 1.5×10 5 Pa, stop hydrogen filling, start to heat up;

[0052] Raise the temperature in the crystal furnace to about 2050 °. The power of the crystal furnace used in this embodiment is 31 kilowatts at this time. At this time, it is found that the powder melts, and obvious liquid streamlines appear near the seed crys...

Embodiment 2

[0060] In this embodiment, a light red ruby crystal with a size of 220×120×40 mm and a lighter color is prepared, and the preparation method includes:

[0061] Select 3193.60g of 5N polycrystalline alumina and 6.40g of 5N chromium oxide powder, and put them into a boat-shaped molybdenum crucible with a size of 220×120×40mm;

[0062] Put the crucible containing the raw materials into the horizontal oriented crystal growth furnace, put a heat shield around it, close the crystal furnace, turn on the circulating water, and evacuate to 1×10 -4 Pa, close the vacuum;

[0063] Charge hydrogen to make the pressure in the crystal furnace reach 1.55×10 5 Pa, stop hydrogen filling, start to heat up;

[0064] When the temperature was raised to 31 kW, it was found that the powder melted, and obvious liquid streamlines appeared near the seed crystal. The crucible was moved to bring the seed crystal close to the high temperature area and observed, and it was found that the edge of the see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com