A high ammonia nitrogen autotrophic denitrification device

An autotrophic denitrification and high ammonia nitrogen technology, applied in biological treatment devices, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of easy sludge loss, high cost of chemical treatment, and large consumption , to achieve the effect of reducing the loss of biomass, improving the efficiency of biotransformation and shortening the doubling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

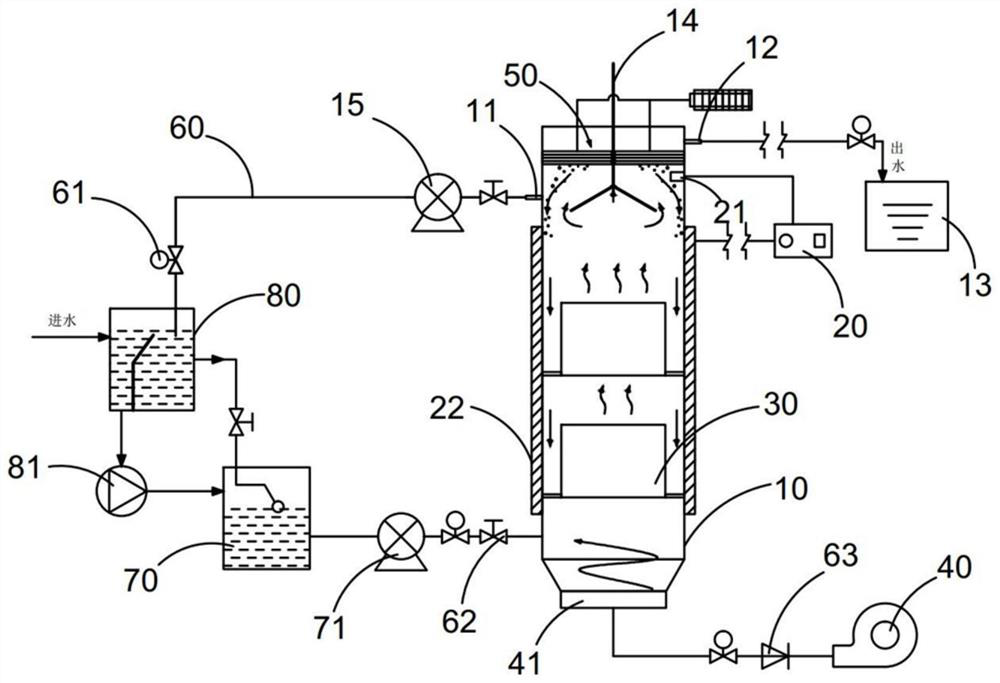

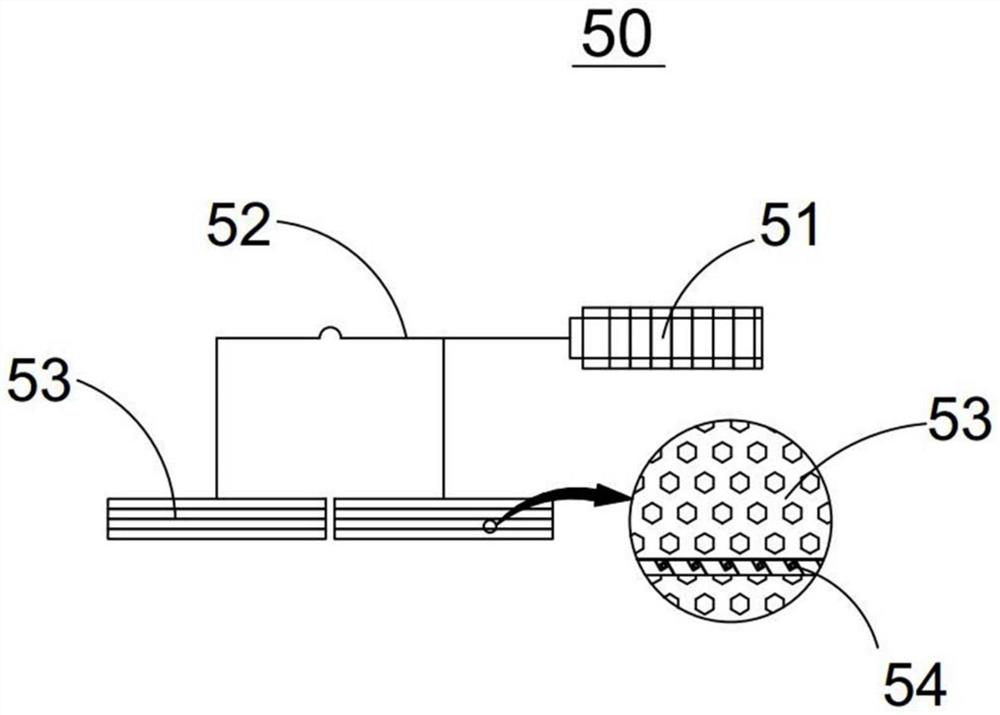

[0033] see Figure 1-7 As shown, a high ammonia nitrogen autotrophic denitrification device, including:

[0034] The reactor main body 10, the reactor main body 10 is a columnar structure, the bottom of which is connected to the third pump body 40 for aeration through the delivery pipe body 60, and the third pump body 40 is connected to the delivery pipe body 60 at the bottom of the reactor main body 10 A flow meter 61 and a check valve 63 are provided. The reactor main body 10 is made of plexiglass. The flow meter 61 is used to count the input oxygen flow, and the check valve 63 is set to prevent the backflow of oxygen or water. The oxygen supply mode is intermittent aeration mode, which is used to inhibit NOB (nitrite oxidizing bacteria). The whole process is carried out under micro-aerobic conditions. The ammonium oxidizing bacteria provide a substrate and provide an anaerobic environment to inhibit the growth of NOB. The reactor main body 10 used in this embodiment is a p...

Embodiment 2

[0049] The difference from Example 1 is:

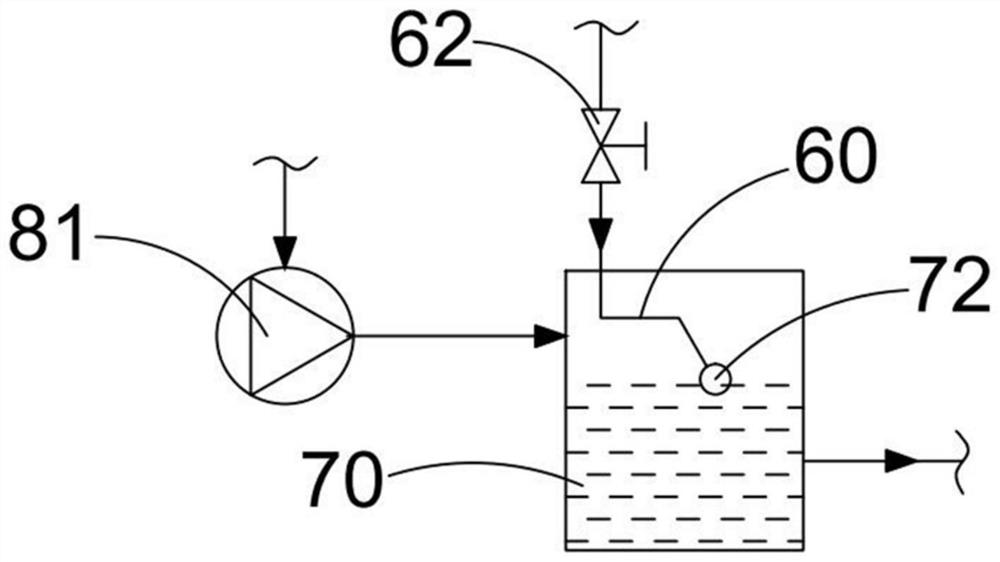

[0050] See attached Figure 7 , the delivery pipe body 60 that the return pipe 11 is connected with the pretreatment box 80 is provided with a denitrification treatment box 82, and denitrification bacteria are cultivated in the denitrification treatment box 82. A small amount of nitrate will be produced during the anaerobic ammonium oxidation reaction process, and the total TN concentration of the effluent can be further reduced through the reflux treatment process and the denitrification treatment tank 82, so as to improve the denitrification efficiency of the system, and an electric heater is installed in the water inlet tank 70 90. It is used to heat the water body. The cultured microorganisms have different active reactions at different water temperatures. In order to treat sewage with different water temperatures, the electric heater 90 is used to control the temperature of the water entering the reactor main body 10 to ensure th...

Embodiment 3

[0052] In this embodiment, a kind of high ammonia nitrogen autotrophic denitrification device of embodiment 1 is used for sewage treatment operation, as follows:

[0053] Inoculated sludge: The sludge inoculated in the reactor main body 10 is nitrosation (flocculent) sludge and anaerobic ammonium oxidation (granular) sludge. In the middle stage of the reactor start-up, the secondary sludge of the traditional urban sewage treatment plant is added to the reactor. Activated sludge in sedimentation tanks.

[0054] Wastewater treatment: the quality of influent water is wastewater with high ammonia nitrogen and low carbon to nitrogen ratio, such as sludge dehydration liquid of urban sewage treatment plants. An external temperature controller is connected with the heating jacket 22 to assist in controlling the water temperature.

[0055] The whole reaction process is avoided to run, specifically, black light-shielding material is used for shielding, and sampling tubes are used for s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com